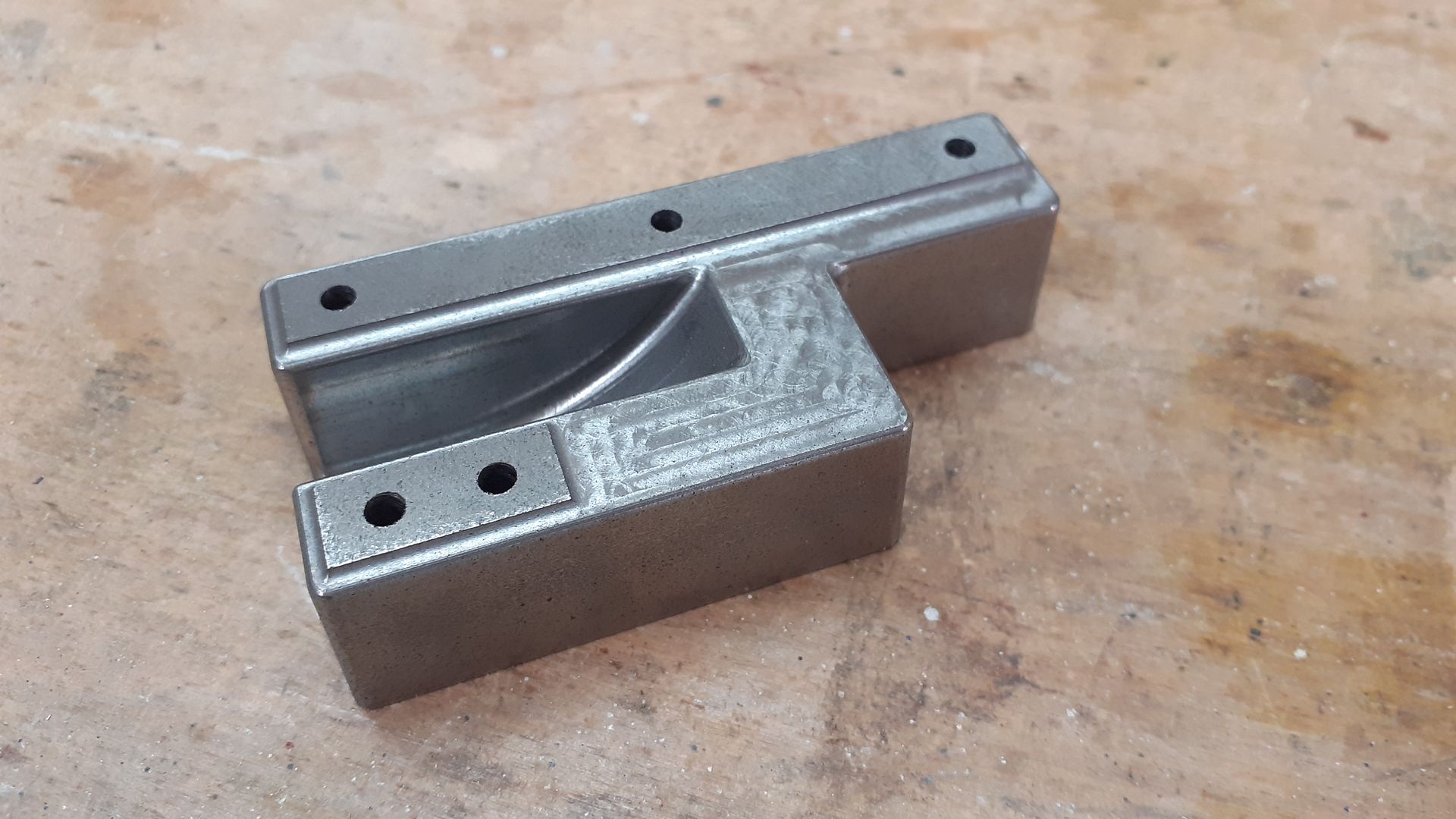

I have seen a few builds across the interwebs that have a very slick flywheel clearance machined into their bases.

I have been racking my brain trying to figure a setup to machine a feature like this on a manual mill or lathe.

Obviously the easy way is to just hog it out to constant depth, but I have seen the feature and cannot figure out

how they did it. Can someone clue me in?

I have been racking my brain trying to figure a setup to machine a feature like this on a manual mill or lathe.

Obviously the easy way is to just hog it out to constant depth, but I have seen the feature and cannot figure out

how they did it. Can someone clue me in?