You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maryak 10

- Thread starter Maryak

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Phil,

Welcome back from your real life : and thanks for your support and interest. :bow:

and thanks for your support and interest. :bow:

A little more progress as another week commences. Made a start on the spray bar as follows.

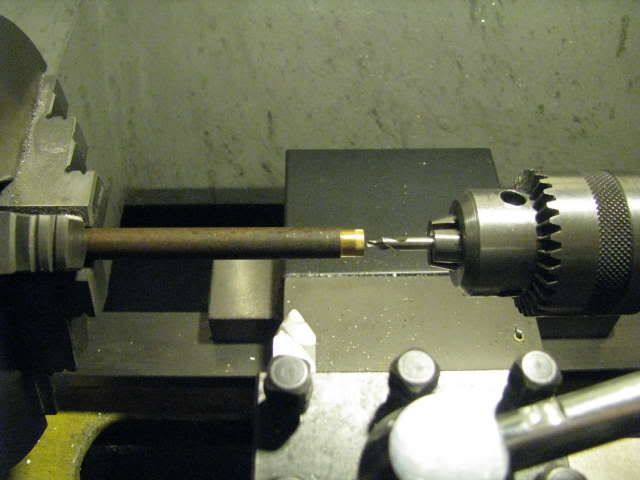

Some brass for the spray bar.

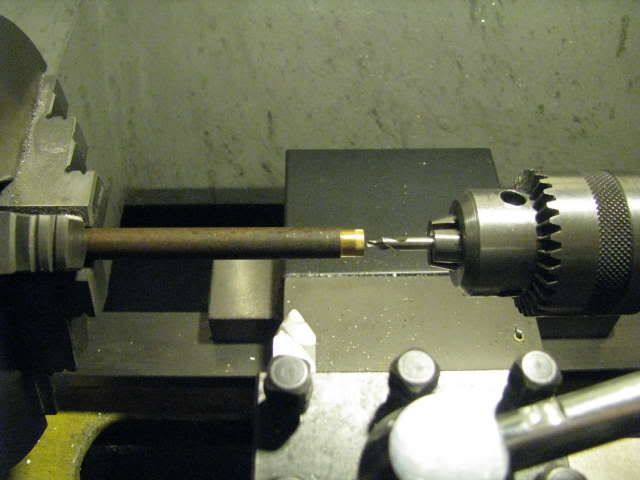

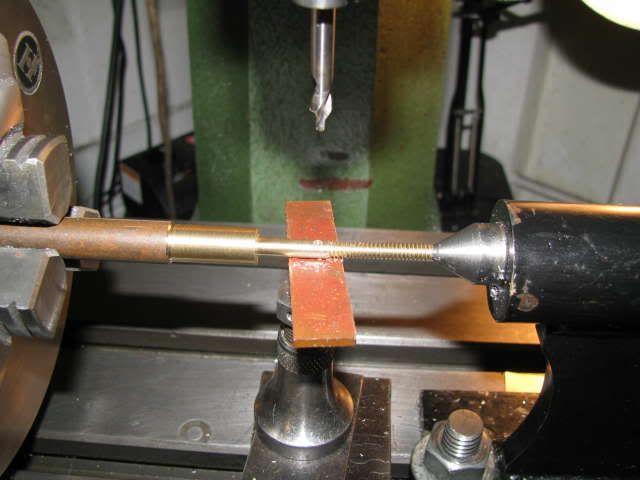

Fiddling with the change wheels to gash the thread before running the die over it.

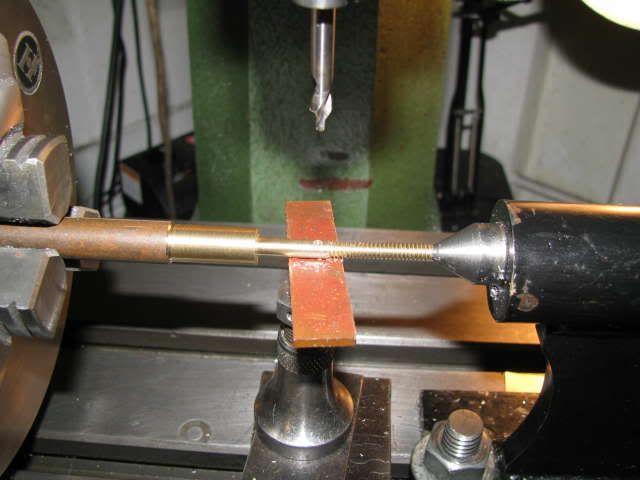

The thread gashed.

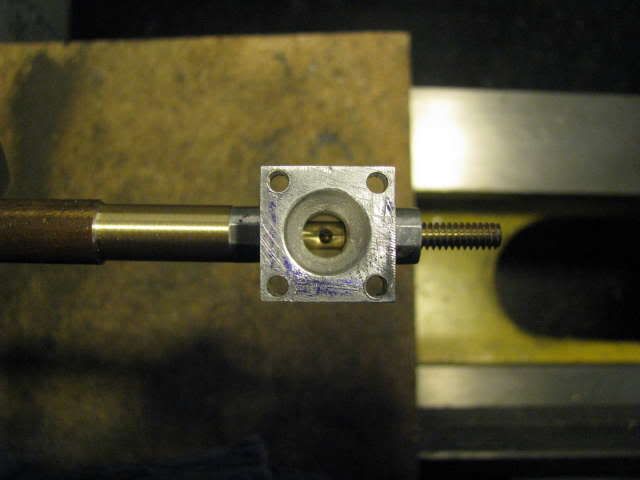

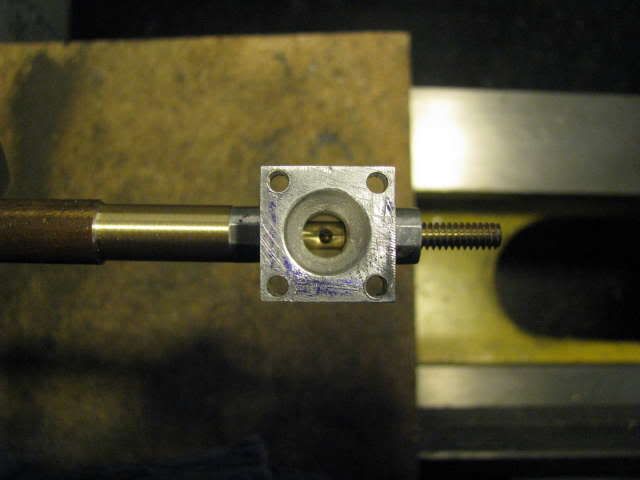

Trial fit of the bar and venturi.

Enough excitement driiling the needle hole I've postponed until tomorrow.

Welcome back from your real life :

A little more progress as another week commences. Made a start on the spray bar as follows.

Some brass for the spray bar.

Fiddling with the change wheels to gash the thread before running the die over it.

The thread gashed.

Trial fit of the bar and venturi.

Enough excitement driiling the needle hole I've postponed until tomorrow.

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Hi All,

Managed to finish the spray bar today now all that is left is the throttle.

Here's what went down.........

Reaming the needle guide using an old needle as the reamer.

Setting up to X drill the fuel outlet hole.

X drilling the outlet hole - As the bar is pretty fragile now, I tried to support it as much as possible.

Seeing is believing - the hole came out in the right place.

Reversed in the lathe and forming the hose tail.

Drilling the needle seat.

Opening out the fuel inlet pipe.

A couple of views of the spray bar assembled in the venturi.

And that's it from him.

Best Regards

Bob

Managed to finish the spray bar today now all that is left is the throttle.

Here's what went down.........

Reaming the needle guide using an old needle as the reamer.

Setting up to X drill the fuel outlet hole.

X drilling the outlet hole - As the bar is pretty fragile now, I tried to support it as much as possible.

Seeing is believing - the hole came out in the right place.

Reversed in the lathe and forming the hose tail.

Drilling the needle seat.

Opening out the fuel inlet pipe.

A couple of views of the spray bar assembled in the venturi.

And that's it from him.

Best Regards

Bob

It's looking really good, can't wait to see it run - there's an engine run down at the aircraft museum on Sunday - perhaps you could start yours up in competition......

Sorry if it's a dumb question but is there a reason you started the thread on the lathe then finished it with a die?

Sorry if it's a dumb question but is there a reason you started the thread on the lathe then finished it with a die?

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Hi Gavin,

Thanks for your support and interest. :bow: :bow:

No dumb questions - only dumb answers, (hopefully not this time). :

3. reasons:

1. As a metric lathe the change gears I have don't allow for accurate cutting of some imperial threads. e.g. 24 tpi.

2. Because this is a pretty small dia I could not get the threading tool deep enough without removing the dead centre - A risk I didn't want to take and I don't have a half centre, (on my roundtoit list).

3. By gashing the thread I was much more confident that the die would run true.

Hope that solves Bob's convoluted thinking for you. ???

Best Regards

Bob

Thanks for your support and interest. :bow: :bow:

No dumb questions - only dumb answers, (hopefully not this time). :

3. reasons:

1. As a metric lathe the change gears I have don't allow for accurate cutting of some imperial threads. e.g. 24 tpi.

2. Because this is a pretty small dia I could not get the threading tool deep enough without removing the dead centre - A risk I didn't want to take and I don't have a half centre, (on my roundtoit list).

3. By gashing the thread I was much more confident that the die would run true.

Hope that solves Bob's convoluted thinking for you. ???

Best Regards

Bob

Bob

Makes perfect sense, I'll remember that if I need to cut a similar thread, I have the AL320G as well, thus far I've only cut metric threads on it. Off topic slightly if I may - what oil do you use when you change the oil in the gearbox of your AL320G?

Rgds - Gavin

Makes perfect sense, I'll remember that if I need to cut a similar thread, I have the AL320G as well, thus far I've only cut metric threads on it. Off topic slightly if I may - what oil do you use when you change the oil in the gearbox of your AL320G?

Rgds - Gavin

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Gavin,

I used Shell Tellus 68 which is on of their hydraulic oils and is SAE 20. Main reasons are SAE 20 is the correct viscosity, reasonable demulse characteristics, mild EP pack and I obtained it for free, (the true reason :

: ).

).

I also use it as straight cutting oil.

Best Regards

Bob

I used Shell Tellus 68 which is on of their hydraulic oils and is SAE 20. Main reasons are SAE 20 is the correct viscosity, reasonable demulse characteristics, mild EP pack and I obtained it for free, (the true reason

I also use it as straight cutting oil.

Best Regards

Bob

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

I like the trick with the two squares. Now I need to get a second myself.

Any reason you couldn't drill the cross hole before turning it down?

Any reason you couldn't drill the cross hole before turning it down?

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

kvom,

Thanks for your support and interest. :bow:

My main worry was that the shaft would be too weak to handle the threading, whichever way it was done and with the axial hole drilled 1st you know exactly when to stop X drilling.

Best Regards

Bob

Thanks for your support and interest. :bow:

My main worry was that the shaft would be too weak to handle the threading, whichever way it was done and with the axial hole drilled 1st you know exactly when to stop X drilling.

Best Regards

Bob

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Hi Guys,

Not much went down today.

We are off to Harvey Bay Qld in the morning for our 50th re-union of my intake into the RAN, (Jan 1959).

Should be a good bash with lots of tall stories and many many anecdotes. Will be back next Tuesday.

Small amount as follows:-

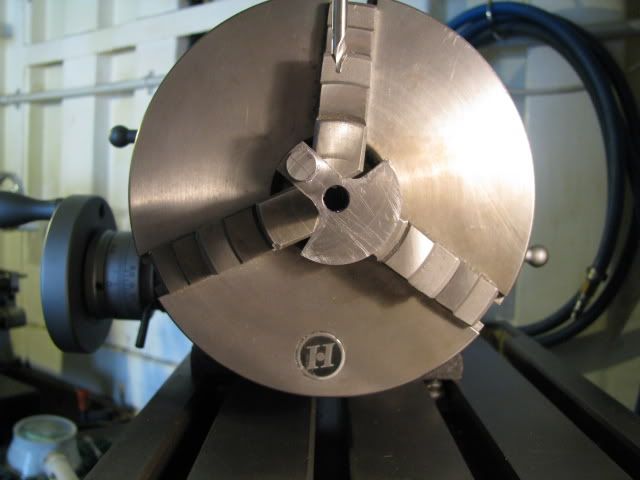

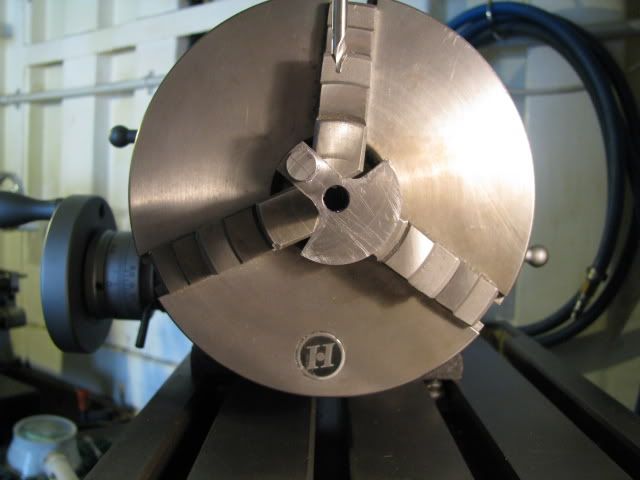

The needle valve holder knurled.

Tapping the holder.

Trial fit on the spraybar.

See yu'all later

Bob

Not much went down today.

We are off to Harvey Bay Qld in the morning for our 50th re-union of my intake into the RAN, (Jan 1959).

Should be a good bash with lots of tall stories and many many anecdotes. Will be back next Tuesday.

Small amount as follows:-

The needle valve holder knurled.

Tapping the holder.

Trial fit on the spraybar.

See yu'all later

Bob

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Hi All,

Finished the spray bar/throttle assembly and drilled the inlet valve hole in the crankshaft.

The spray bar with throttle reamer offered to the engine.

Setting the needle valve prior to soft soldering in position.

The completed carburettor/throttle/spraybar, can anybody think of any more names. ???

Setup for drilling the inlet valve hole in the crankshaft.

Have a great day

Bob

Finished the spray bar/throttle assembly and drilled the inlet valve hole in the crankshaft.

The spray bar with throttle reamer offered to the engine.

Setting the needle valve prior to soft soldering in position.

The completed carburettor/throttle/spraybar, can anybody think of any more names. ???

Setup for drilling the inlet valve hole in the crankshaft.

Have a great day

Bob

Maryak said:The completed carburettor/throttle/spraybar, can anybody think of any more names. ???

Gizmo

Gizmatic

Gizmatron

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

steamer said:I hope Mrs Maryak is not looking in vain for that pack of needles? ;D

Looking good Bob! I can almost hear it running!

Dave

Thanks Dave for your continued support :bow: It almost never pays to needle SWMDBO

stevehuckss396 said:Gizmo

Gizmatic

Gizmatron

Bill Mc said:vaporizer, atomizer,fuel mixing valve

Thanks Steve and Bill :bow:

I Really like GIZMATRON or БЕНЗОКОЛОНКА.

Best Regards

Bob

Similar threads

- Replies

- 115

- Views

- 34K