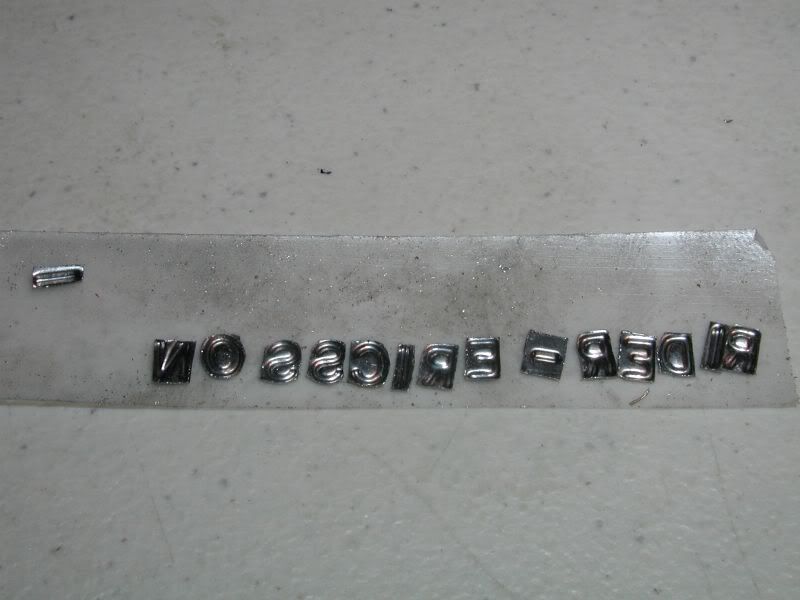

Tried making some raised letters to get that cast look and it seems to work OK.

Having a little homemade cnc mill was able to mill out some mirrored image letters about .040" deep in some 1/16" thick Teflon sheet that was handy. Believe there is a way to have made the same letters using a UV cured rubber and your art work or using a wax instead of the Teflon.

With a scalpel cut a chamfer around the letters, this gave somewhat of a fillet to bottom of the letters when cast. Mixed up some steel filed epoxy and smeared into the letters with some excess.

Was able to wrapped the Teflon sheet around a 1/2" steel shaft by starting at one end and wrap tightly working to far end.

Let set about 12 hours before removing Teflon sheet. With a sharp scalpel went around the letter edges and put a little chamfer on them. The J-B weld epoxy was easy to carve as it had not completely set up. Sanded lightly to make the top surface more uniform in height.

Finished heat exchanger on model of Rudy Kouhoupt's steam tractor.

Question, are the attached pictures too large, should they be a smaller size?

Having a little homemade cnc mill was able to mill out some mirrored image letters about .040" deep in some 1/16" thick Teflon sheet that was handy. Believe there is a way to have made the same letters using a UV cured rubber and your art work or using a wax instead of the Teflon.

With a scalpel cut a chamfer around the letters, this gave somewhat of a fillet to bottom of the letters when cast. Mixed up some steel filed epoxy and smeared into the letters with some excess.

Was able to wrapped the Teflon sheet around a 1/2" steel shaft by starting at one end and wrap tightly working to far end.

Let set about 12 hours before removing Teflon sheet. With a sharp scalpel went around the letter edges and put a little chamfer on them. The J-B weld epoxy was easy to carve as it had not completely set up. Sanded lightly to make the top surface more uniform in height.

Finished heat exchanger on model of Rudy Kouhoupt's steam tractor.

Question, are the attached pictures too large, should they be a smaller size?