- Joined

- Jul 8, 2007

- Messages

- 628

- Reaction score

- 14

I will be able to use it but its just no fun to machine. A little 110vac smithy does not like it.

I got the outboard side done nice but Im not going to do much extra cutting on the side against the engine frame.

At my brothers shop most anything large is in flatbar and needs flamecut or is 4140. I did not see any good soft steel in the 2.500 size range.

I did get some 6" peices of 3/16",1/4",5/16",3/8",1/2" of 1018 and the 3/8" is some type of stainless.

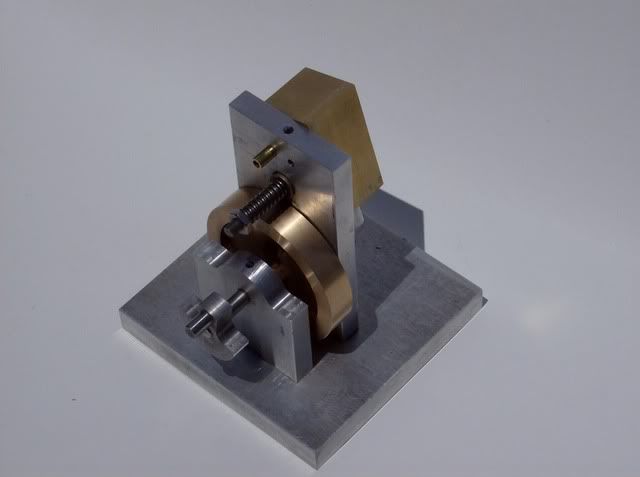

One cool deal is a friend was there who works at a screw machine shop is going to round me up a bundle of brass bar ends from 1/4" - 1-1/4" round at work and give them to me.

I will load up on softer metals every chance I get from now on.

I got the outboard side done nice but Im not going to do much extra cutting on the side against the engine frame.

At my brothers shop most anything large is in flatbar and needs flamecut or is 4140. I did not see any good soft steel in the 2.500 size range.

I did get some 6" peices of 3/16",1/4",5/16",3/8",1/2" of 1018 and the 3/8" is some type of stainless.

One cool deal is a friend was there who works at a screw machine shop is going to round me up a bundle of brass bar ends from 1/4" - 1-1/4" round at work and give them to me.

I will load up on softer metals every chance I get from now on.