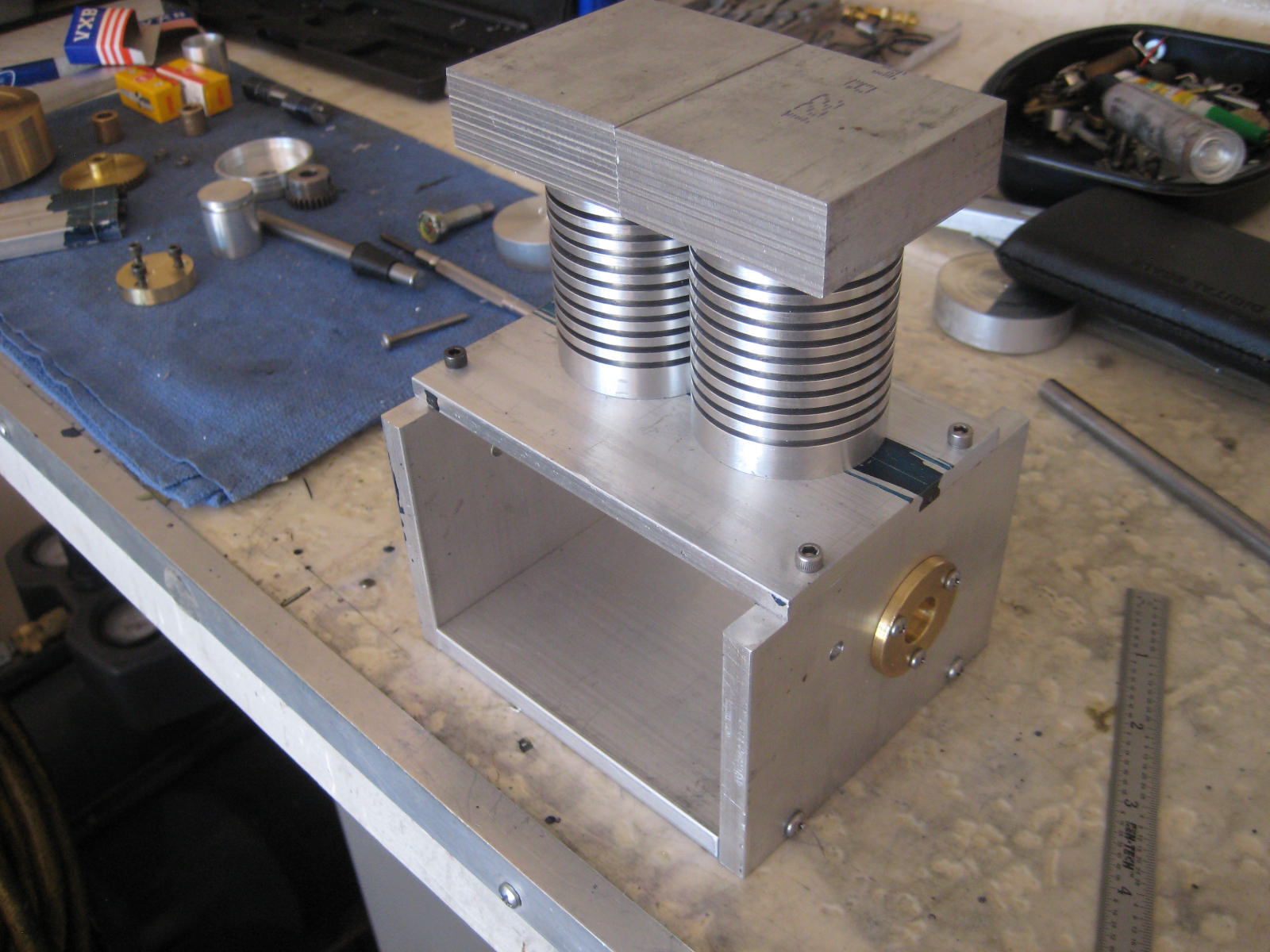

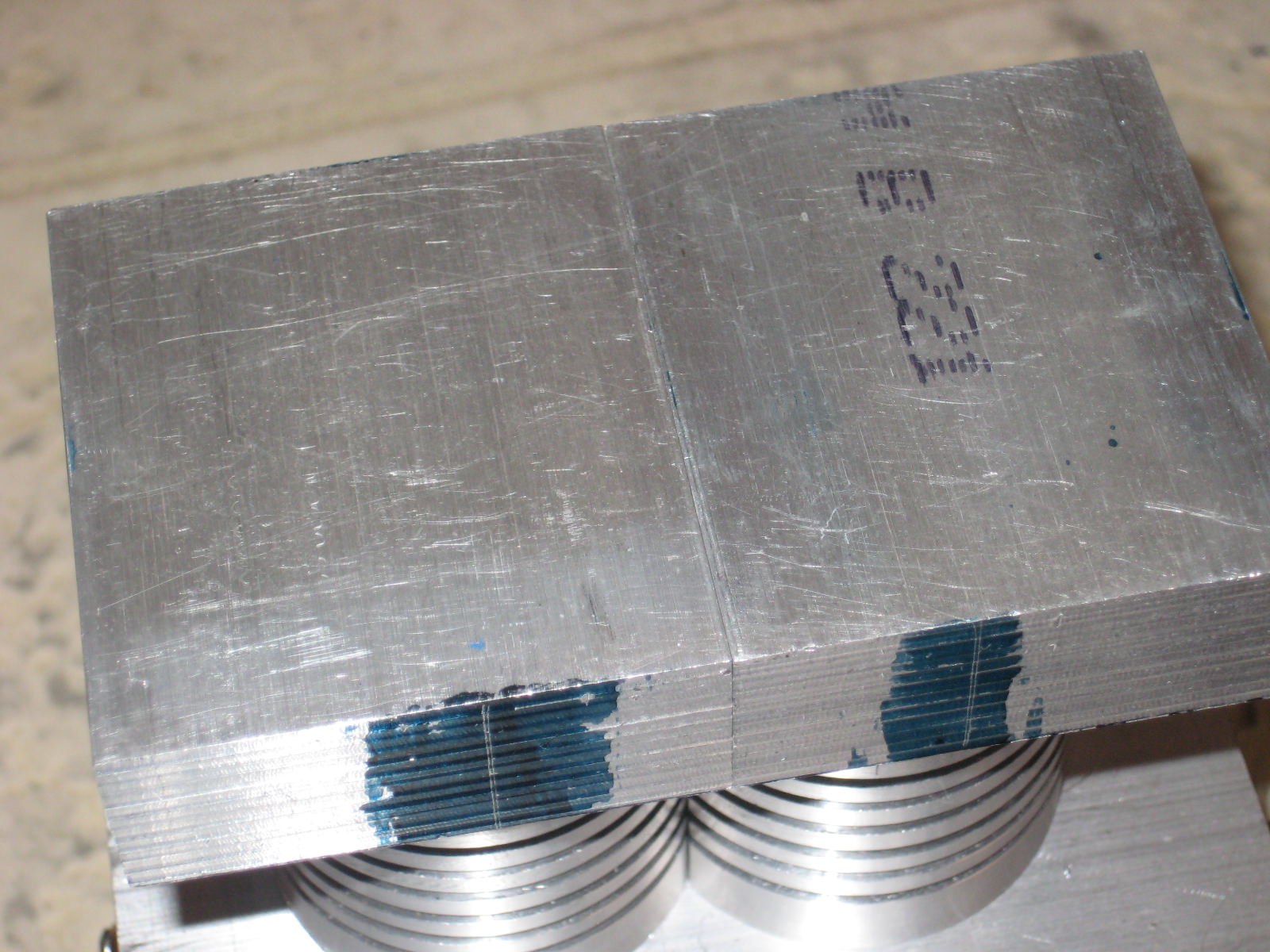

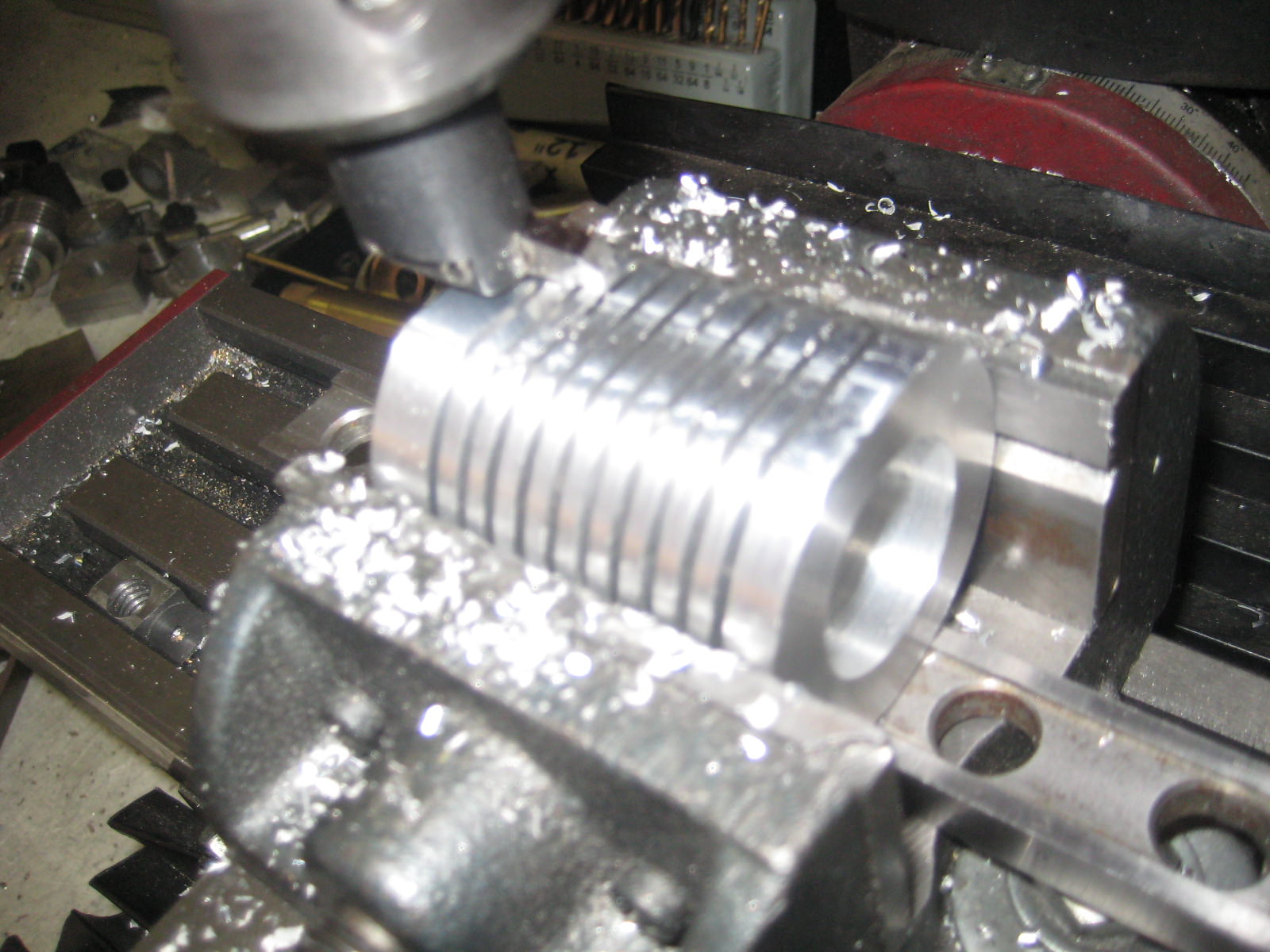

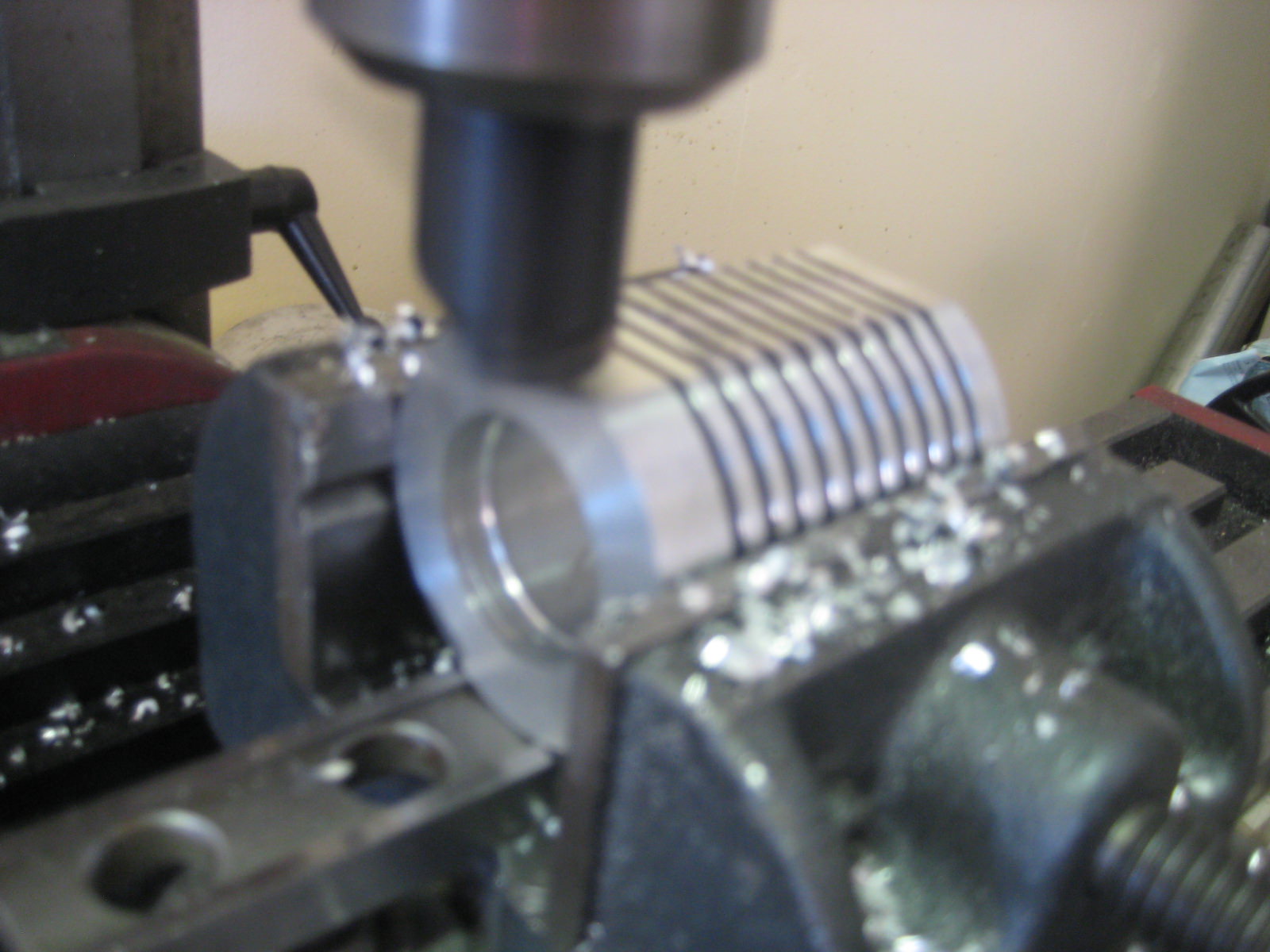

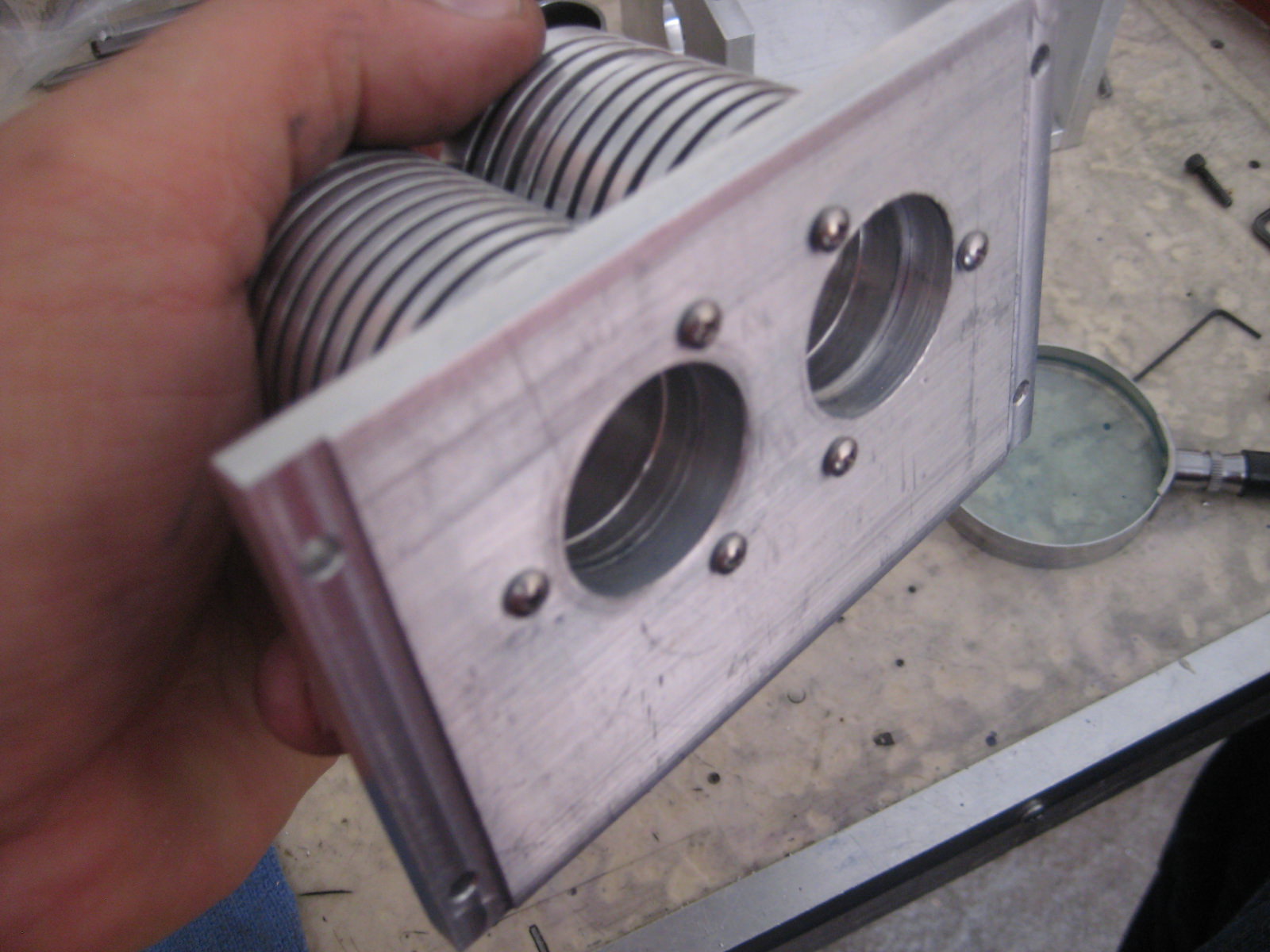

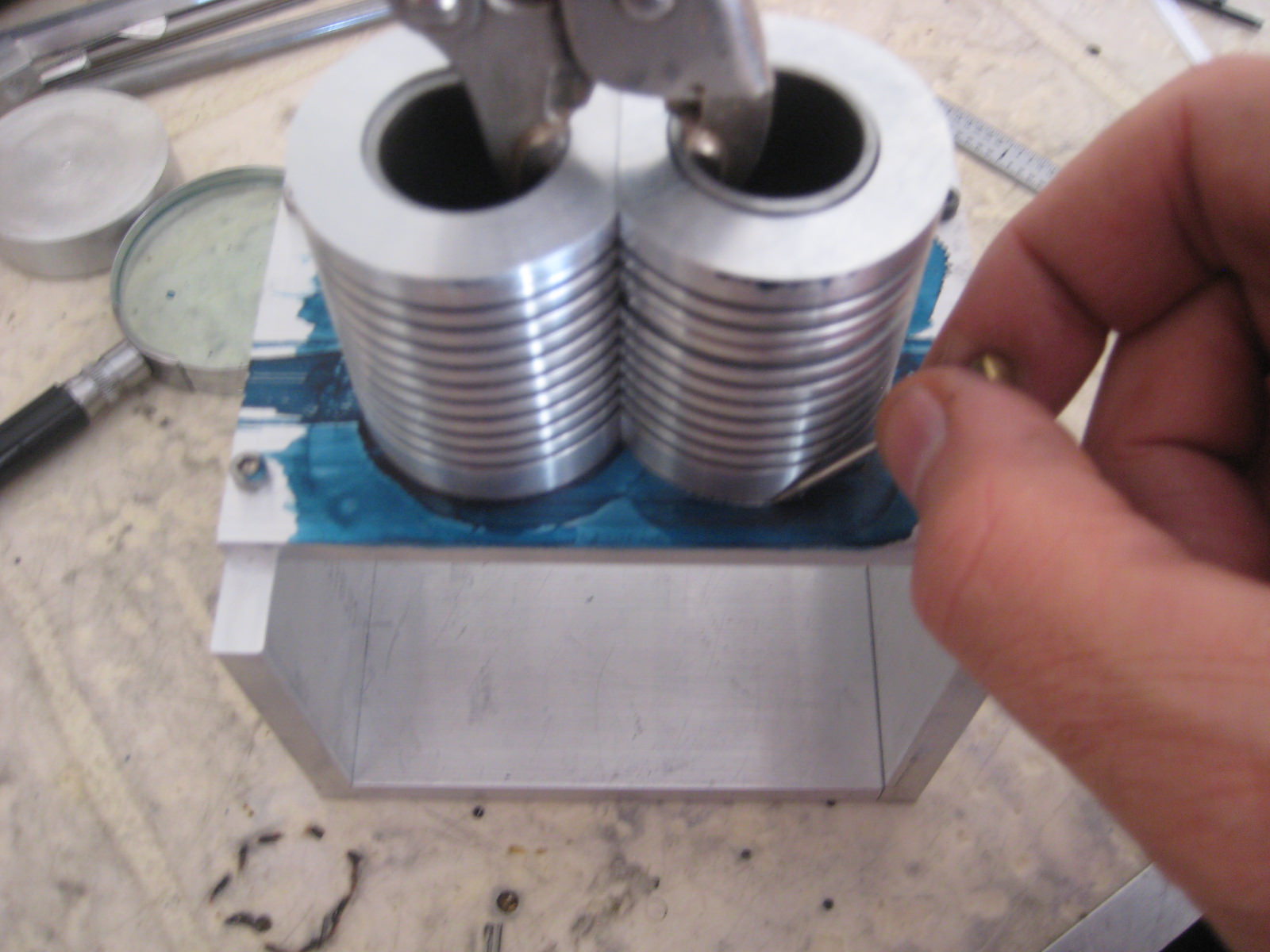

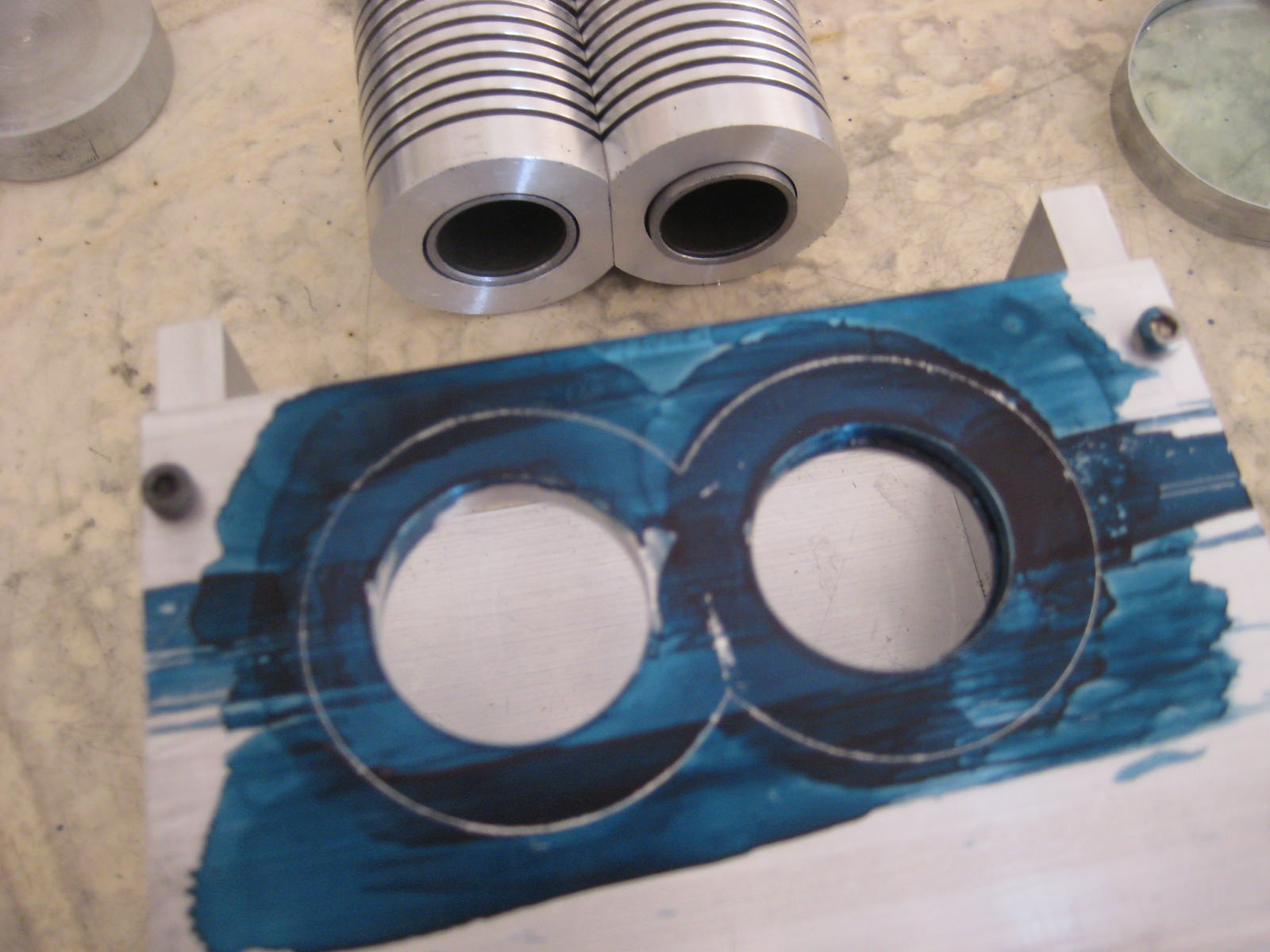

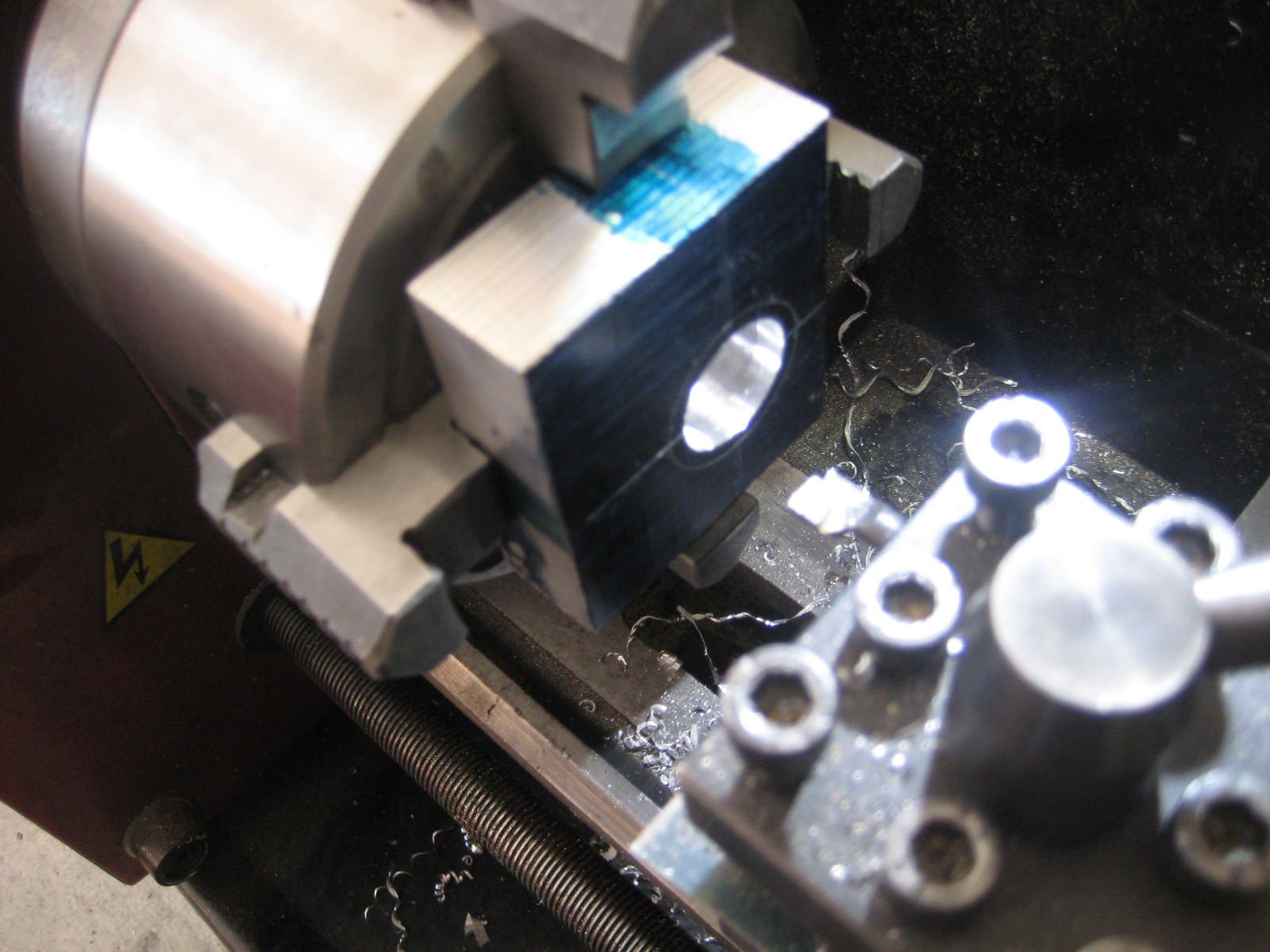

About 3 yrs. since I built my first I/C twin engine. My "GEMINI" is a good start but I want another crack at an inline twin to address a couple of shortcomings in its build. Can I make improvements in service, durability and add a new feature using basic machine shop know how and NO PLANS  in the same scale? scratch.gif .....The story of "OVERTIME" starts this weekend!

in the same scale? scratch.gif .....The story of "OVERTIME" starts this weekend!

Last edited: