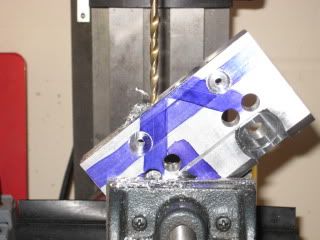

The radiators where flat milled and butted up against each other installed on the deck of a new angle frame. Still plenty of room for the o-ring gaskets.

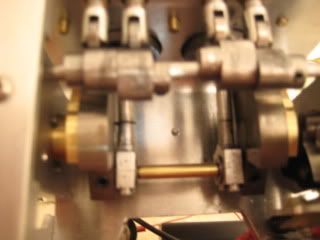

Back to where I was now, the new crankshaft configuration turns easily by hand with the end plates drawn tight to frame and crank throw pin locked in the webs. The flywheel side bearing carrier now sports an Oilite bushing in place of the three R1810ZZ bearings which remain in the crankshaft nose bearing carrier.

The muffler shown here was soldered to the head pipes, after a few minutes running the bond failed. A new larger diameter muffler stuffed with stainless pot scrubber material was secured using a flanged threaded collar and sounds better.

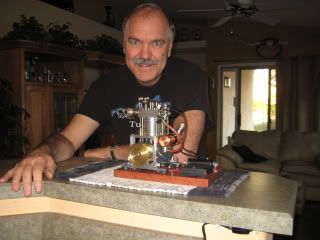

The intake is 5/8in. Delrin to independent intake ports and supplied by a TRAXXAS carb. Just like automotive practice where they use moulded intakes to keep fuel systems cooler, the carb never gets hot in running.

The slab side of angle frame. You can hang a couple of spare tires here......maybe a life boat. :big: But we all know the fuel tank resides here! Gemini dances on four rubber feet from Ace Hardware.

Crankshaft thrust control is with bushings up against the roller bearrings. If the crank "walks", it will cock your con rods causing binding up in the piston and stall the motor. A brass pulley for accessory drive finishes off the crank nose.

Come back tommorrow for the conclusion, the beauty shots and see GEMINI run! Thm:

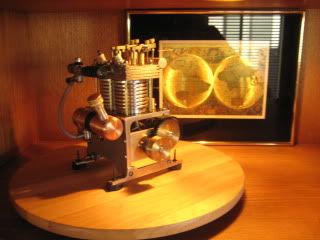

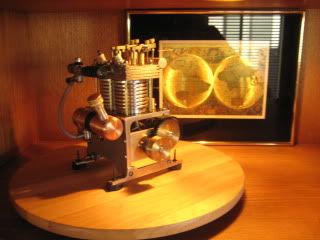

I have a couple single cyl. I/C's and wanted to advance up to a muti-cyl. engine. 2 cylinders is a basic step, let me have at it! With ideas starting up, I went to Windows paint ( the poor mans CAD) and layed out a few basic 2D drawings. The GEMINI twin is the result.

I have a couple single cyl. I/C's and wanted to advance up to a muti-cyl. engine. 2 cylinders is a basic step, let me have at it! With ideas starting up, I went to Windows paint ( the poor mans CAD) and layed out a few basic 2D drawings. The GEMINI twin is the result.

An open 360 crank design of 20 CC's its first run was Nov. 27th. Some disapointments in the journey. Along the way I had to remake the crank webs and cyl. head and I learned alittle bit more from the experiance. The GEMINI story starts this weekend.

An open 360 crank design of 20 CC's its first run was Nov. 27th. Some disapointments in the journey. Along the way I had to remake the crank webs and cyl. head and I learned alittle bit more from the experiance. The GEMINI story starts this weekend.