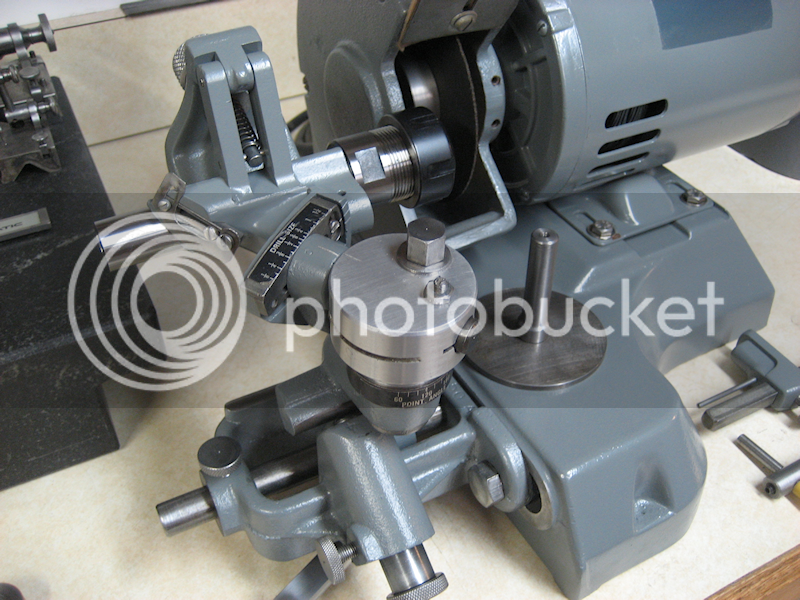

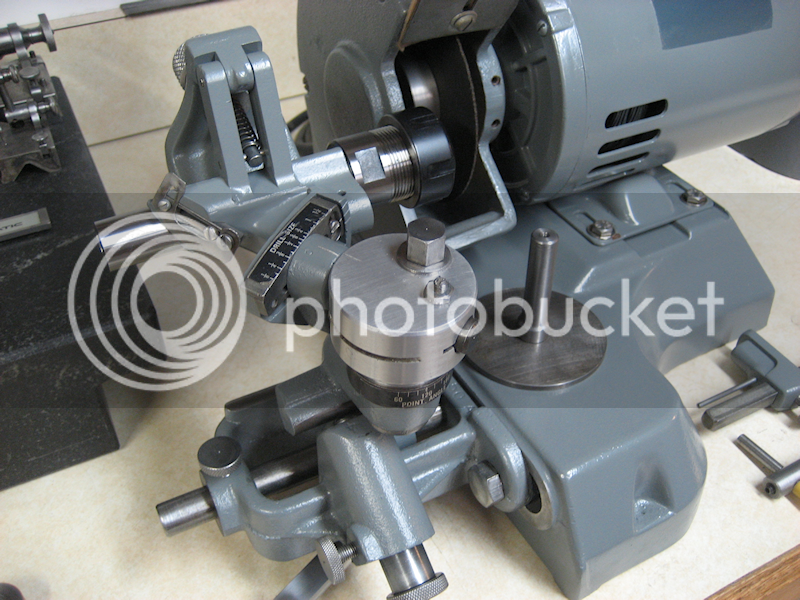

My brother-in-law had given me a Lisle 91000 drill grinder that was pretty neglected. I was able to clean it up and make some modifications to make it more usable and wanted to share with everyone.

The first mod was to drill out the pin that held in the drill holder and replace it with a tapered pin, so I could remove it when I did not need it. It really sticks out there and makes it hard to store.

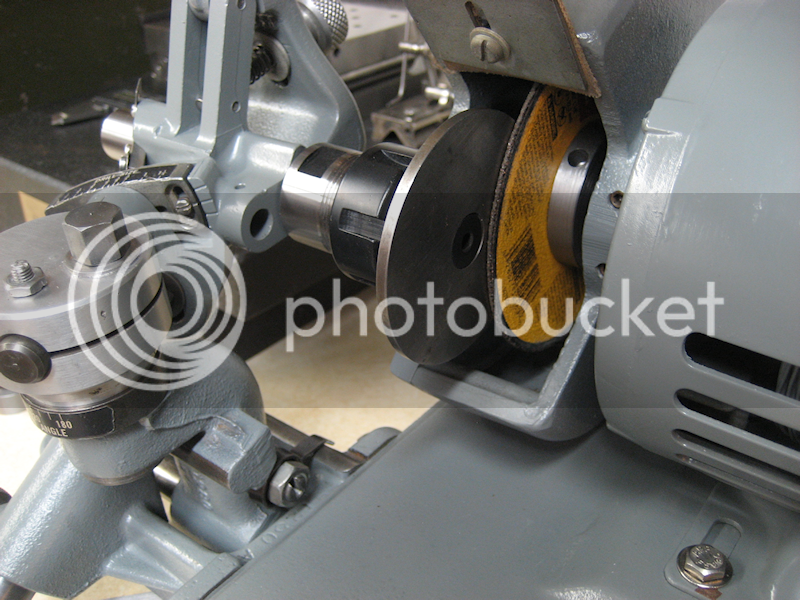

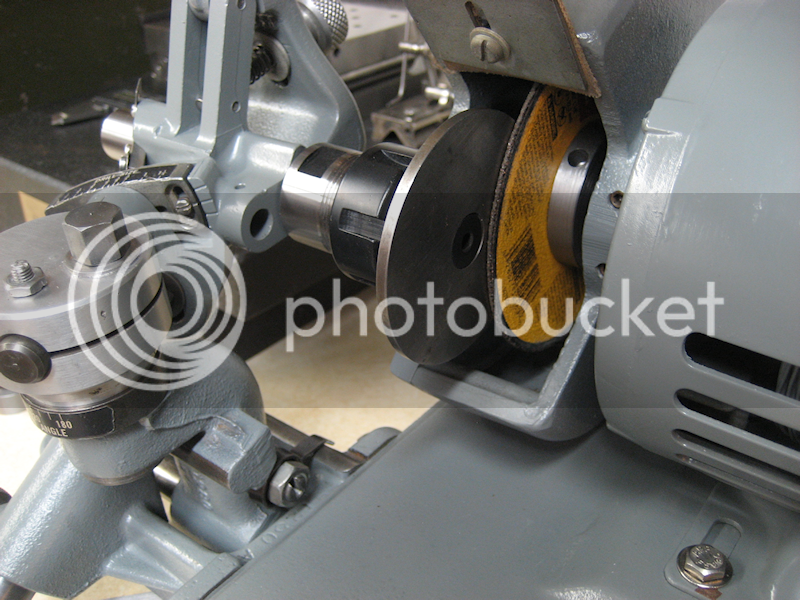

I also made a stop collar for the X axis, so I can control the depth, and a 7/8 arbor for the cutoff wheels with a LH thread.

Lastly, I ordered an ER-25 extension, since I already have a full set of ER-25 collets.

Since my Benchmaster Milling machine uses 2mt collets, I am always having to cut down tooling to fit in them, so now I can use this grinder as a cutoff saw, so I also made a disk that can be used to quickly align the tool holder for this purpose.

Eventually I will add an indexing adapter for the ER-25 extension to fit into so I can touch up the end of end mills, oh and of course for sharpening drills

The first mod was to drill out the pin that held in the drill holder and replace it with a tapered pin, so I could remove it when I did not need it. It really sticks out there and makes it hard to store.

I also made a stop collar for the X axis, so I can control the depth, and a 7/8 arbor for the cutoff wheels with a LH thread.

Lastly, I ordered an ER-25 extension, since I already have a full set of ER-25 collets.

Since my Benchmaster Milling machine uses 2mt collets, I am always having to cut down tooling to fit in them, so now I can use this grinder as a cutoff saw, so I also made a disk that can be used to quickly align the tool holder for this purpose.

Eventually I will add an indexing adapter for the ER-25 extension to fit into so I can touch up the end of end mills, oh and of course for sharpening drills