canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

I agree with Brian. If you haven't used CAD before, start with 2D. This will be VERY beneficial when you move to 3D.

In 3D modeling, the first thing created is the 2D sketch & is the basis of the 3D geometry. If you have a sloppy 2D

Sketch (unconstrained, bad dimensioning scheme..) this "simple" 2D sketch can create many problems further

down the road in your model. (You might have to change a Dim in that sketch & it may not give you the results

You want)

John

I must disagree on this one John.

I started my 'drawing career' learning AutoCAD 12 (2D) For me it was a never ending learning process..! . I was not busy drawing a part on my computer, no I was busy drawing lines on a screen. I got nuts drawing lines...!

Until someone proposed to try Inventor 7. Starting Inventor 7 was kind of a revelation. After a few minutes I had opened the program I drew my first 3D parts. There were a gazillion fewer conventions to work with the program compared with AutoCAD, Inventor is easy to learn, intuitive.

The most important issue about Inventor (and other 3D software) : while drawing 3D parts, your 2D drawings are automatically generated out of that 3D part....!

Putting these 2D drawings 'on paper' takes you literal a few seconds. You click and there is your front view, click again and you have an additional view, left, right, upper, you name it, only seconds to do that. Add some figures to the drawings and your done.

And of course larger companies still use 2D software. They have a long life licenses (and support) to deal with. Not one new company will invest in 2D software anymore.

cant agree with you more AutoCAD LT2007 was users freindly, since then it's a hide and seek where they hide the ICONComplexity and user friendliness was all downhill from there... and I followed along with many AutoCAD releases to finally settle into AutoCAD LT 2007. Of course, AutoSketch was seriously limited on the output device side of things... imagine no PDF output.

How about posting drawings of what you have done then let him decide what he really wants? Honestly you wind up starting your drawing in 2d with any cad program, then just extrude it. so you are learning 2d cad as well. But the end result is way coolerLOL

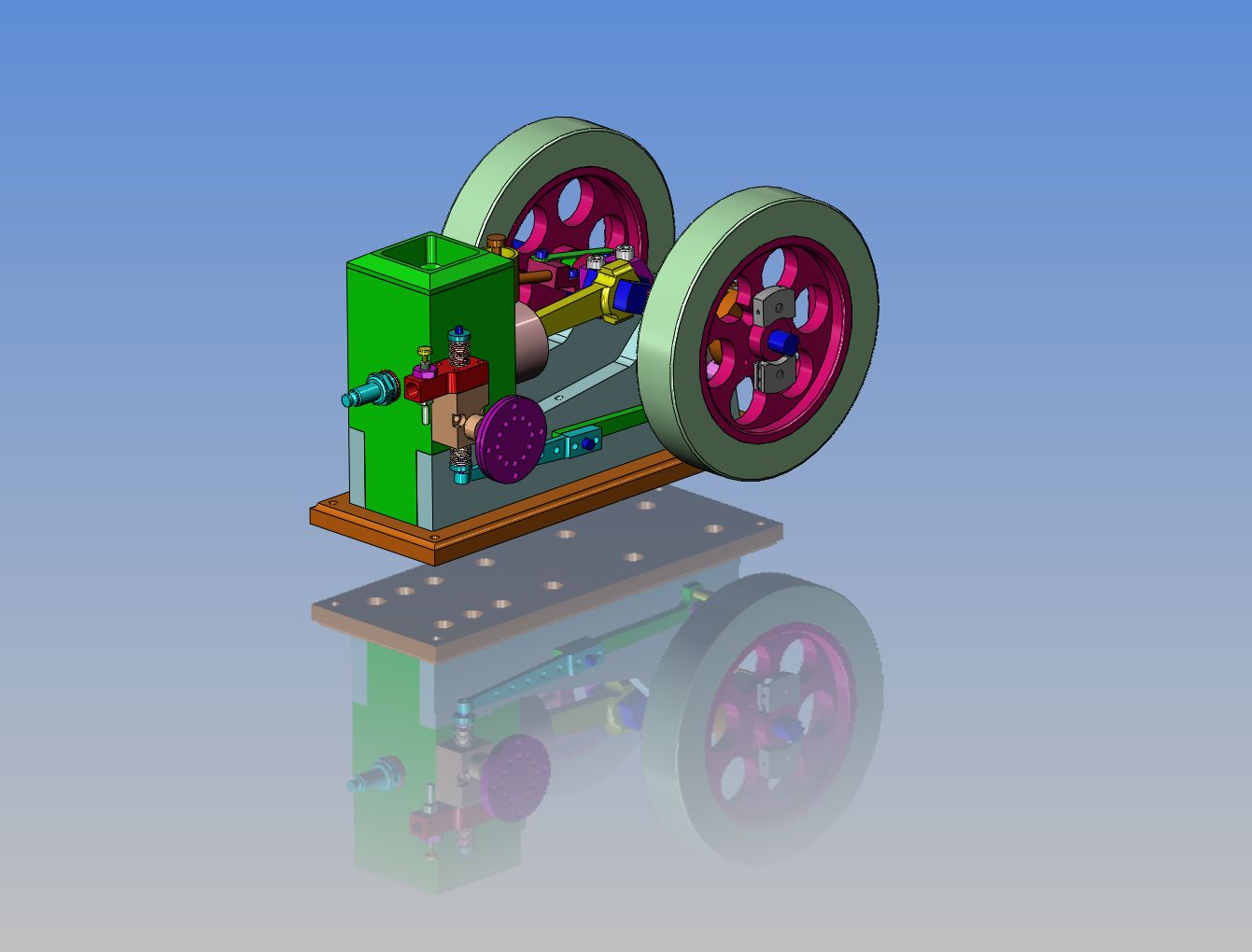

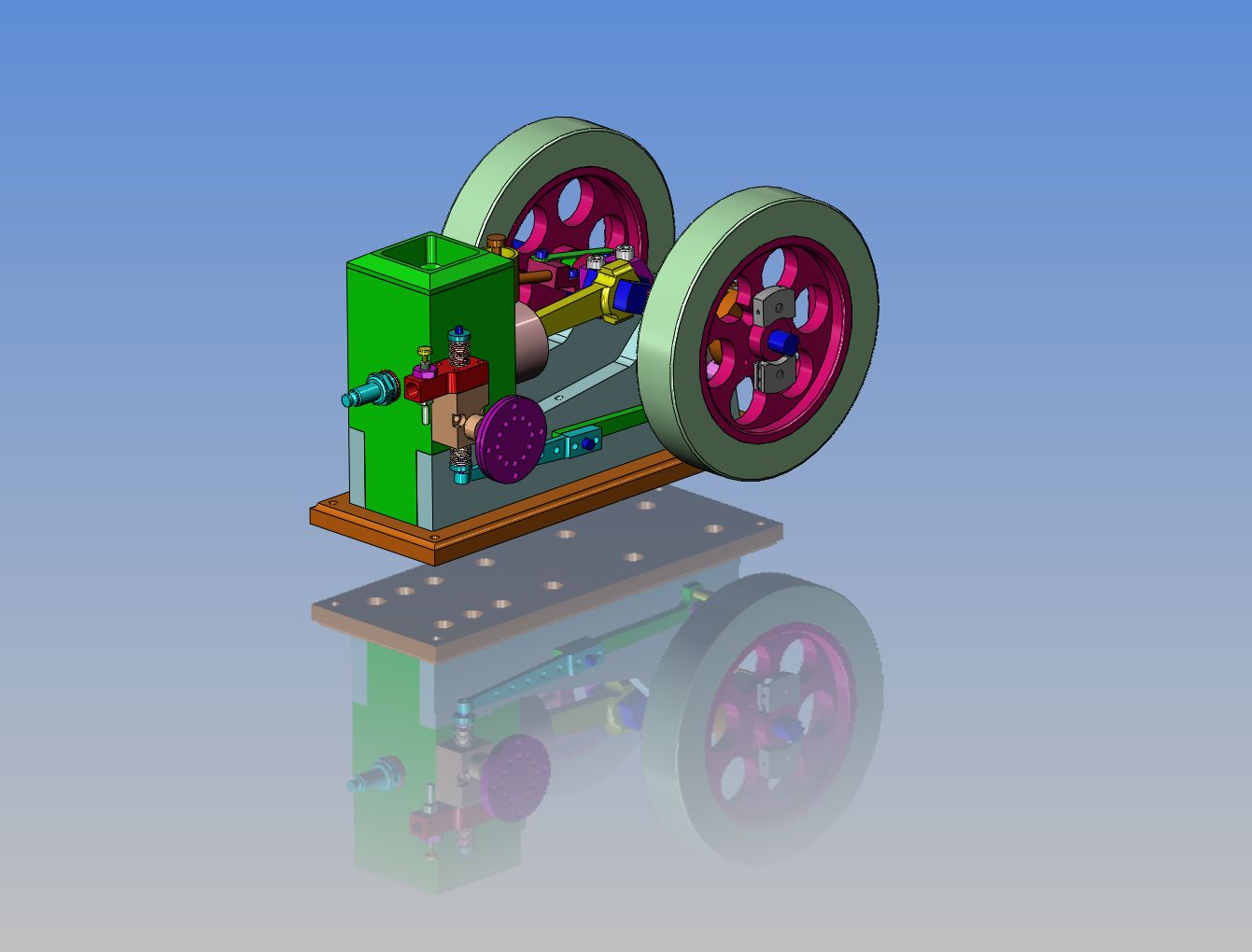

Yes, the 3D cad shurely does make them pretty. But, as I said, every part in the model started with a 2D dimensioned sketch. Given that there are some really great free 2D packages, and NO free 3D packages, I still recommend starting with 2D. Find your way around in it, then move to 3D if you want to make pretty models. Just remember---No matter how pretty and impressive the 3D models are, its still 2D drawings that get issued to the shop floor for machinists to work from, and its still mainly 2D .dxf files that go to the shop for cnc programming. For many people who are hobby machinists, thats enough.---Brian

I really do appreciate everyones replys, but after wasting 2 hours of Dave Sohlstrom's life last night he has me on track with alibre.. Im drawing up plans and printing them out, nothing to detailed mind you. More detailed drawings will come with practice me hopes lol...Thanks everyone..And mostly you dave !! Thanks a bunch...Bill

It all depends on whether you want to learn CAD in order to do some actual working drawings, or works of art to impress everyone and I'm not talking about any of you guys - I like to see that sort of stuff too! but I'm trying to say that if you are designing and building a project that you only need to satisfy yourself as to how much detail you will need in order to get the job done.

Not of course begrudging anyone having the higher end programs you understand! but with the really great ones, doing really great drawings and renderings often becomes the main focus and the actual engineering often gets shelved!

Sure you can have Solid Works and be a master of graphics (all at great cost), or you can be a practical engineer in your little shed actually desigining and making stuff, in which case you can download a trial version of DESIGN CAD which is perfectly adequate for doing a real job - They (Design Cad) will give you the full version for $80 (or $100 if you didn't download the trial from the IMSI site) when its time has expired, this is for Version 22 with 3D. - that's also much cheaper than Turbocad.

You don't need to be a master draughtsman (draftsman to Americans )in order to design your own engineering project.

This one is quite easy, - every cad program has a steep learning curve of course, but just have patience and it'll all come to you! -like riding a bicycle it will always stay with you - Check it out!

Enter your email address to join: