lazylathe

Well-Known Member

- Joined

- Aug 27, 2009

- Messages

- 1,285

- Reaction score

- 6

Hi All,

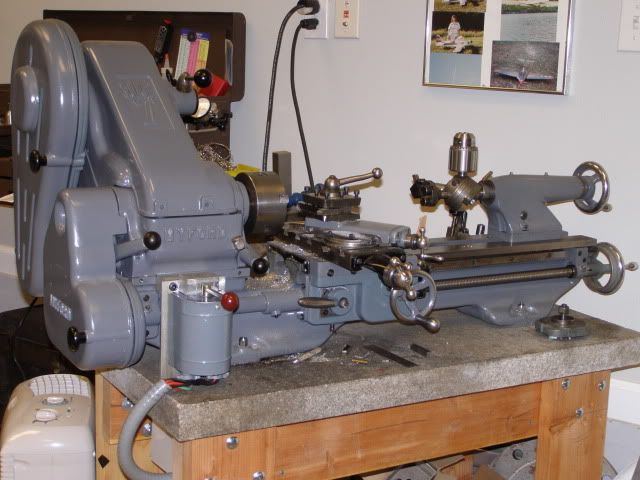

In a few weeks i will be getting my new toy! A Myford ML7!

In the interim i need to make a suitable bench for it.

It will come with a metal chip tray so that will provide some protection for the bench from oil etc.

I have searched the forum and seen a lot of wooden benches.

Are they dimensionally stable? And what is the best type of wood to make them from?

I have a lot of woodworking tools so throwing one together carefully is not an issue.

The metal ones i have seen cost a fortune!

And buying a pair of cast iron legs gets very expensive quickly!

I read a lot about benches and how the wooden ones will swell with temperature changes, humidity changes and just weather in general.

To me it seems that metal is the ideal choice, but not so when looking around machining forums.

What are good options to add to a bench?

Levelling system for the legs?

Drawers and storage space is essential.

Don't really want a backboard or peg board, just a clean lined bench.

Any suggestions or tips would be greatly appreciated!

Thanks in advance!

Andrew

In a few weeks i will be getting my new toy! A Myford ML7!

In the interim i need to make a suitable bench for it.

It will come with a metal chip tray so that will provide some protection for the bench from oil etc.

I have searched the forum and seen a lot of wooden benches.

Are they dimensionally stable? And what is the best type of wood to make them from?

I have a lot of woodworking tools so throwing one together carefully is not an issue.

The metal ones i have seen cost a fortune!

And buying a pair of cast iron legs gets very expensive quickly!

I read a lot about benches and how the wooden ones will swell with temperature changes, humidity changes and just weather in general.

To me it seems that metal is the ideal choice, but not so when looking around machining forums.

What are good options to add to a bench?

Levelling system for the legs?

Drawers and storage space is essential.

Don't really want a backboard or peg board, just a clean lined bench.

Any suggestions or tips would be greatly appreciated!

Thanks in advance!

Andrew