- Joined

- Jan 19, 2010

- Messages

- 1,193

- Reaction score

- 41

Thanks Bob, Kevin, and Dean.

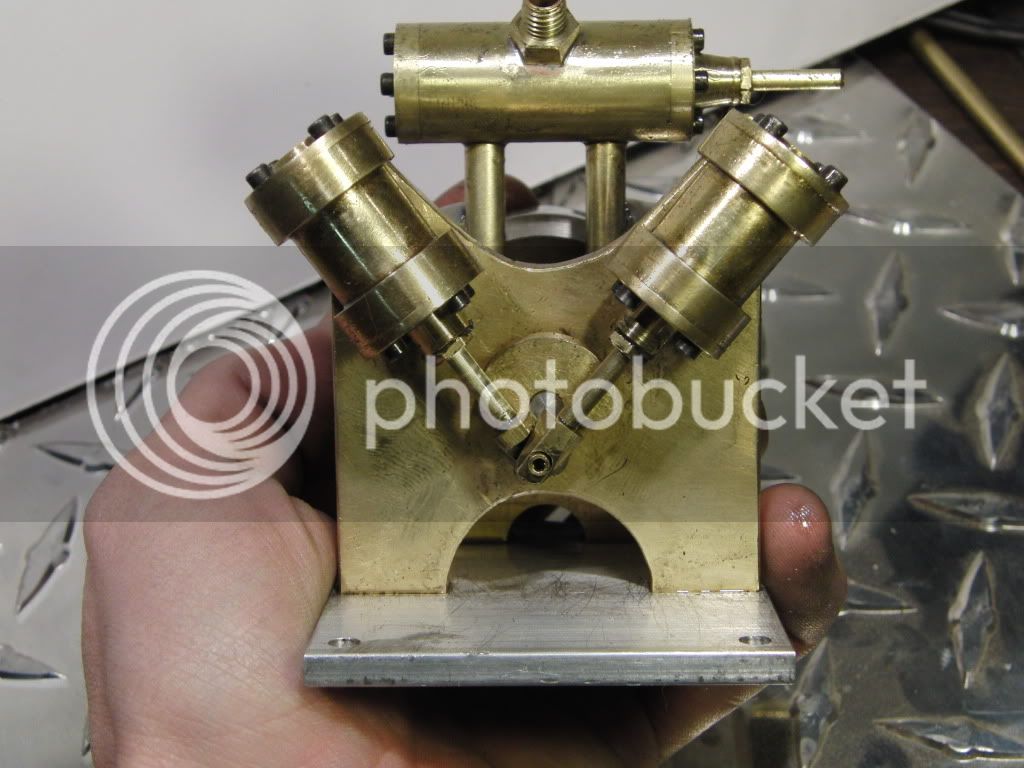

I was very happy when she turned over for the first time without any major fiddling. It has actually been about 5 years in the making, more or less. This was my Third attempt at this engine. 1 complete failure and 1 quasi-failure. The phrase "We learn from our Mistakes" could not be any more true. When it came time to build the parts I already knew what didn't work, so it was just a matter of properly making the little guy.

I guess you could say my rivalry with this engine has finally come to an end............for know.

I am planning on making a boiler for this just like the plans. It is a water tube boiler and pretty straight forward construction. Just a matter of getting all the materials needed for the job. Who knows, the whole boat maybe.

Thanks for lookin

Kel

I was very happy when she turned over for the first time without any major fiddling. It has actually been about 5 years in the making, more or less. This was my Third attempt at this engine. 1 complete failure and 1 quasi-failure. The phrase "We learn from our Mistakes" could not be any more true. When it came time to build the parts I already knew what didn't work, so it was just a matter of properly making the little guy.

I guess you could say my rivalry with this engine has finally come to an end............for know.

I am planning on making a boiler for this just like the plans. It is a water tube boiler and pretty straight forward construction. Just a matter of getting all the materials needed for the job. Who knows, the whole boat maybe.

Thanks for lookin

Kel