Jereon (& others)

Thanks for your kind words. Thm:

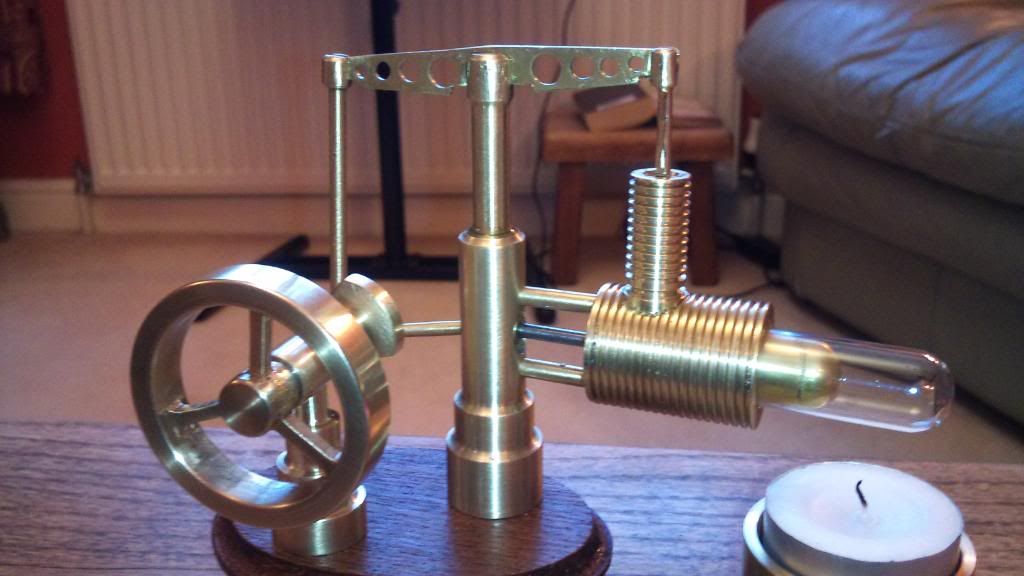

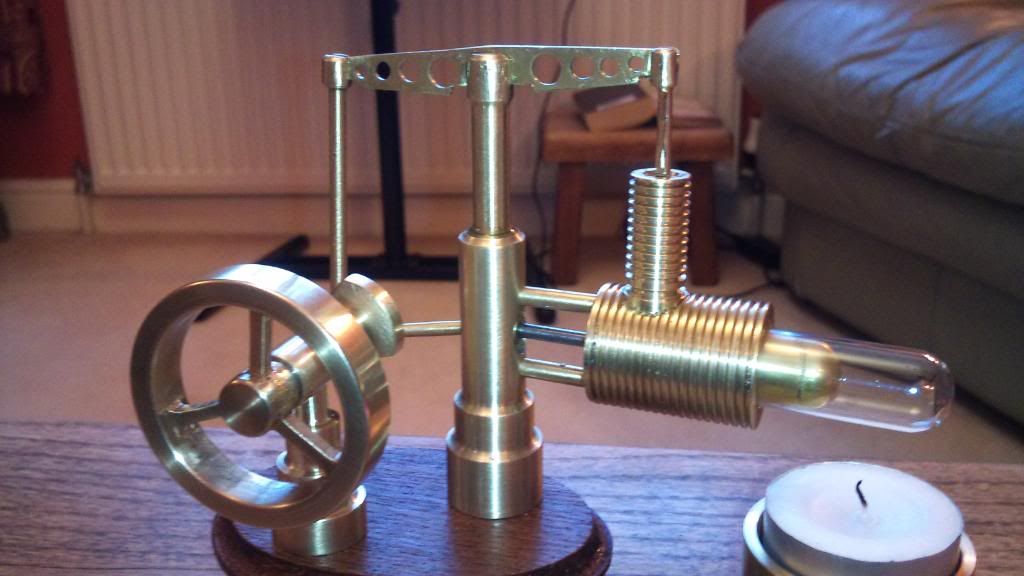

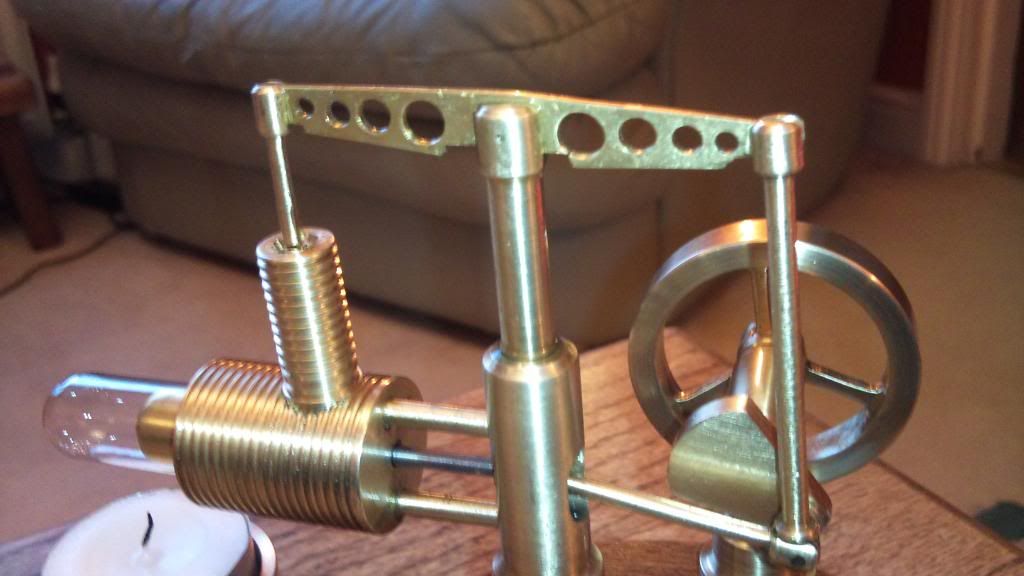

This was only my 3rd small engine build, following a Stuart 10H and a 1.5 scale Gerry's Beam Engine.

Thanks to your plans, the build itself was quite straightforward. The plans, as others have noted, miss two linkages but I found that the best with these was to build the rest and then accurately measure what was required to connect it all up. :idea:

I only have minimal tools, the majority of the work being done on my Myford ML7 (I don't have a milling machine - any milling is done on the ML7)

The build was done over 5 days during Christmas, with another 3 days spent getting it running.

For others thinking about this engine, the difficult areas are:

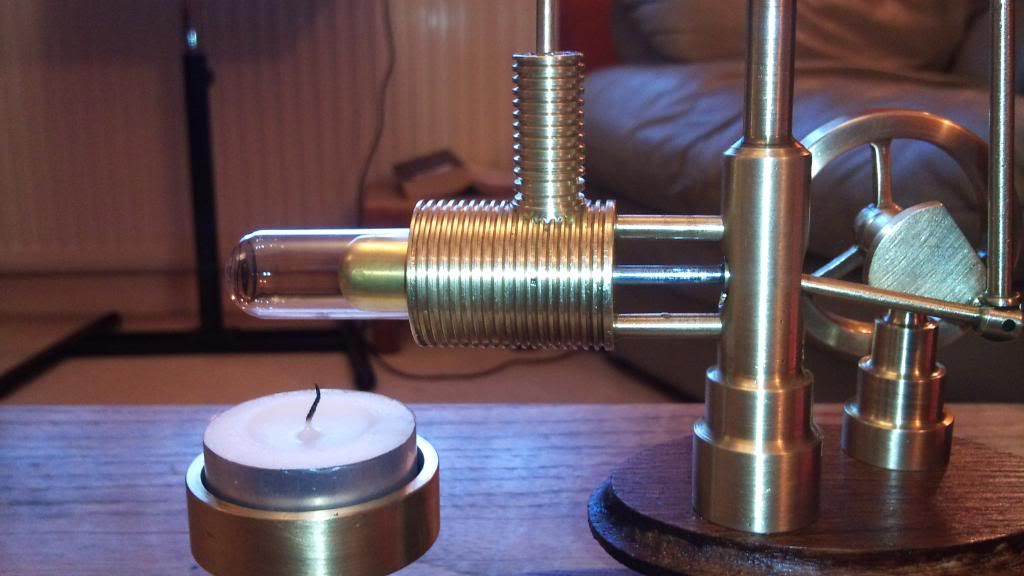

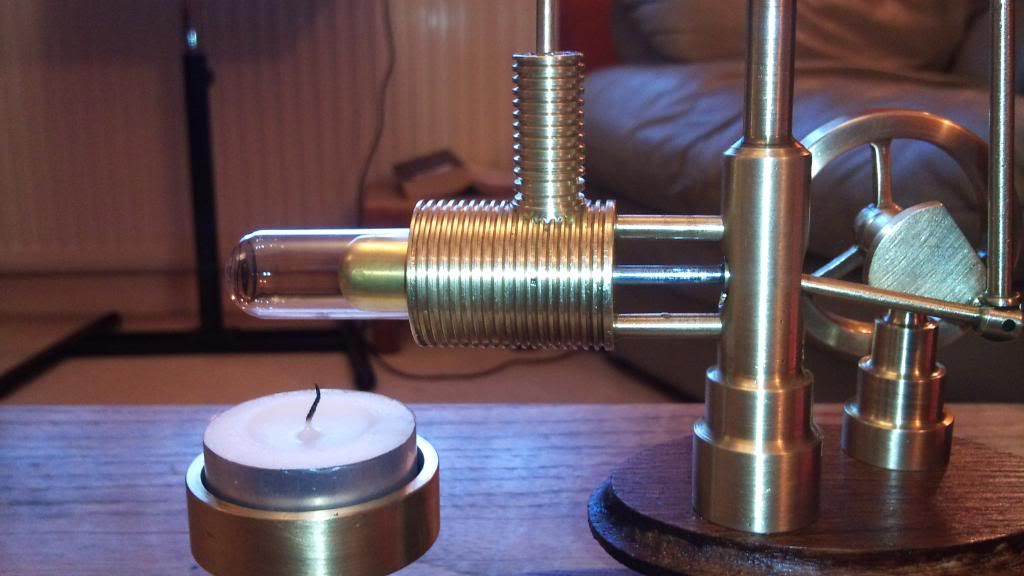

Cutting the test tube! - I got through 7 using various methods, ending fairly successfully with a small triangular file, basically filing around until it finally snapped. Frustrating but tubes are quite cheap off ebay so not a great problem. scratch.gif

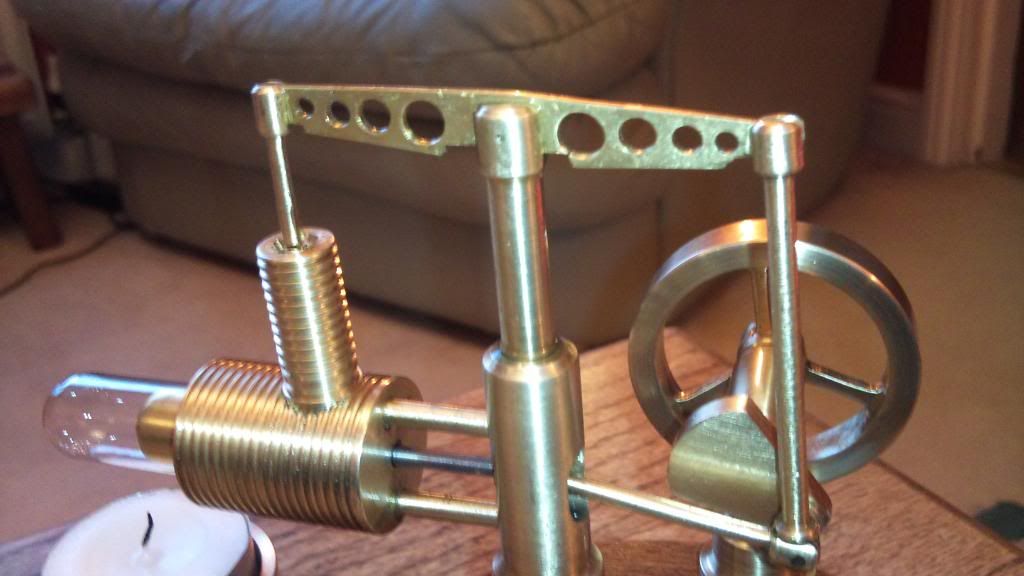

Displacer bearing was another part which caused me some grief. I tried Graphite but this turned out to be too brittle (maybe the wrong type of graphite??). I ended up with a simple brass one (displacer rod is silver steel)

Once together, it was all still too stiff. A while running it driving the flywheel with the lathe loosened it up enough. Despite your words, light oil on the displacer rod does help!

As I put earlier, it will run from the tea light but I need to put the flame right against the tube which soots it up. Running from a 'Mamod' parafin tablet is clean but a bit too hot - the whole thing heats up too quick and stops running after 5 mins or so. No big issue.

What would I do different? - two things, the flywheel axle bearing mount onto it's stand is only pushfit/loctite. I would thread this as it keeps coming apart (only using superglue probably doesn't help).

similarly, the displacer rod end could be threaded to ease assembly/disassembly to get to the displacer bearing. Otherwise build to plan and it works!!

Again thanks to you Jeroen for doing the hard work to get this sorted and drawn to start with. :bow:

Next project? probably the Jan Ridders Thermo Pulse Mobile - looks straightforward but I expect it to be a challenge... :wall:

Thanks again guys

Dave