Lew Hartswick

Well-Known Member

- Joined

- Sep 20, 2007

- Messages

- 505

- Reaction score

- 10

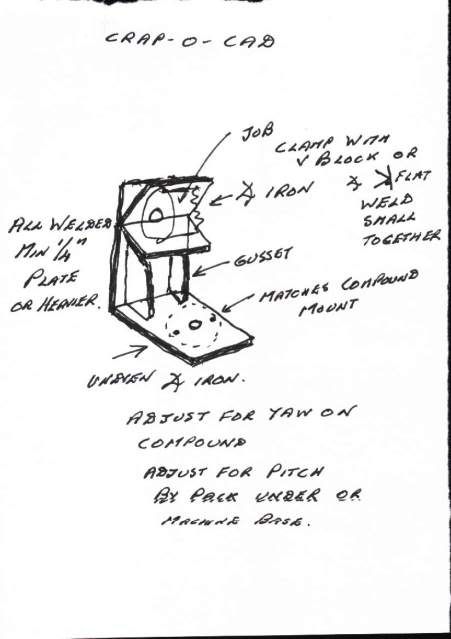

Whatever you call it. The boring bar between the spindle and the tail stock.

I've never seen this done but an application came up at school today (at least I think).

The BIG question Was/is how to hold the work and even more important how to

align the piece in the vertical direction and the pitch yaw degrees of freedom.

If anyone has a few pictures of mounting an object to do this I'd sure like to see them.

I can picture some sort of bull nose centers in the tail stock and maybe another in

the chuck to get the axis aligned but how in the world to then "grab" the work to do

the boring is beyond me at the present. As another part of this, advancing the cutter

in the required small increments may be a little tricky also.

Thanks for any pointers.

...lew...

I've never seen this done but an application came up at school today (at least I think).

The BIG question Was/is how to hold the work and even more important how to

align the piece in the vertical direction and the pitch yaw degrees of freedom.

If anyone has a few pictures of mounting an object to do this I'd sure like to see them.

I can picture some sort of bull nose centers in the tail stock and maybe another in

the chuck to get the axis aligned but how in the world to then "grab" the work to do

the boring is beyond me at the present. As another part of this, advancing the cutter

in the required small increments may be a little tricky also.

Thanks for any pointers.

...lew...