I have two sets of indexable turning tools. They are surprisingly similar. Both use CCMT inserts (diamond shaped), which I really like. One is a 3/8" made by Glanze. I got it from Grizzly, but I don't think they carry them any more. Glanze are made in India, and they're about. Someone here mentioned having a Glanze set.

My second set was a Micro100. I got them in 1/2", which (barely) fit my AXA holders. They're much more rigid and use the same inserts. Wholesale Tool offers them:

http://www.wttool.com/product-exec/product_id/39819/nm/7_Pc_Indexable_Insert_Holder_Set

I got them on sale, but I can't remember where. I know they weren't $200, but they were not cheap either.

I have the Plastool model as well. It's handy sometimes, but I don't think the insert style performs as well as the CCMT's.

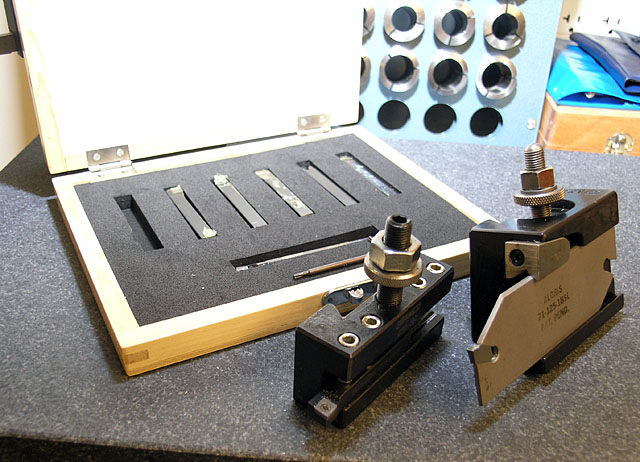

Here are the Glanze tools along with my Aloris cutoff tool:

BTW, there is a trick to finding the "right" CCMT's for small lathes too. This is very important! I've tried lots of inserts, and this is the ticket. I got the tip from a pro who had come across these inserts somewhere.

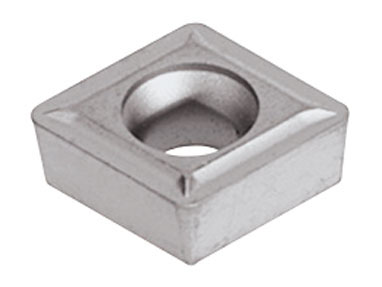

Here is the standard CCMT:

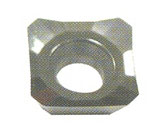

Now here are the "good" inserts:

See how they look like a "little crown"? It's that shape that is the key. They have a lot of positive rake, which is good for small lathes. For a time they were called "CCGT" on eBay, but that's a misnomer. These days I insist on seeing a picture of the insert before I'll buy. The little crowns cut way better and leave a finer finish to boot. It is amazing how much the different insert styles matter on these things.

One last point. The boring bars I've gotten in these turning sets have always been extremely poor. Boring is a demanding job. Look for solid carbide bars from good names. I like Circle bars when I find them cheap enough on eBay.

Cheers,

BW