Aquarius21

Well-Known Member

- Joined

- May 26, 2009

- Messages

- 63

- Reaction score

- 1

Hi, while watchng MIT's great machine shop video on drilling (#2) the instructor

mentioned the concern about a regular steel drill grabbing brass while drilling.

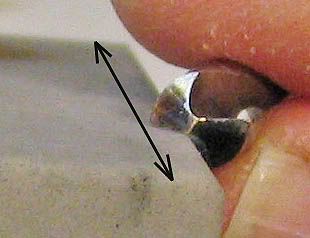

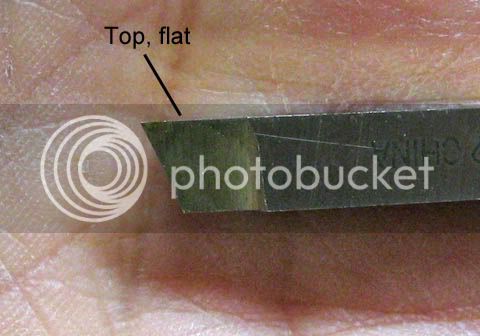

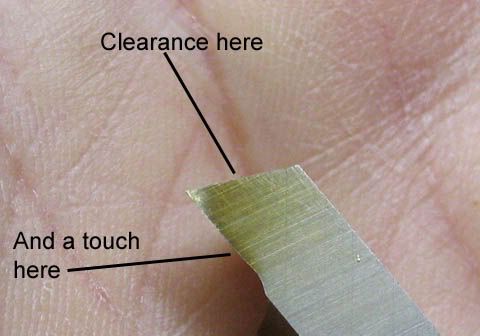

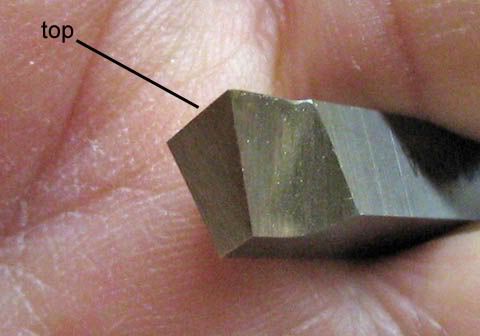

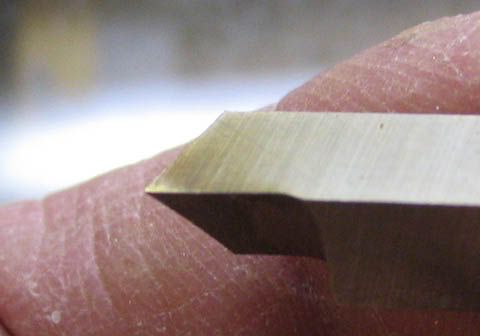

One internet suggestion was to file a flat on the flute to reduce grabbing.

Any suggestions as I would rather not toast a drill either. Do people buy

a separate set of drills for brass? Does one bolt the vise to the drill table?

Drill in a lathe? Your advice is welcomed as the cost of messing up a block

of brass to make the cylinder block for the rotary valve 2 cylinder engine

would be disenheartening ( and to fetch another piece of brass would mean

a hour drive to the city as there are no local suppliers.)

Thanks for helping in this, Quincy, Nova Scotia

mentioned the concern about a regular steel drill grabbing brass while drilling.

One internet suggestion was to file a flat on the flute to reduce grabbing.

Any suggestions as I would rather not toast a drill either. Do people buy

a separate set of drills for brass? Does one bolt the vise to the drill table?

Drill in a lathe? Your advice is welcomed as the cost of messing up a block

of brass to make the cylinder block for the rotary valve 2 cylinder engine

would be disenheartening ( and to fetch another piece of brass would mean

a hour drive to the city as there are no local suppliers.)

Thanks for helping in this, Quincy, Nova Scotia