I finally took delivery of my lathe yesterday and at the moment its precariously balanced on a plank of plywood over my wheel barrow so tomorrow I plan on fixing the cabinet to the floor and with the help of my neighbour (If he is home) fitting the lathe onto it.

I'm wondering how much space everyone leaves around their lathe as obviously space is precious in a small workshop but proper access around the lathe is important too.

I was thinking of leaving a gap from the gearbox to the wall equal to the size of the gearbox cover swinging out plus about 20cm, about 45cm out from the wall and around 50cm clear from the end of the lathe.

Does this seem enough space or should I leave more?

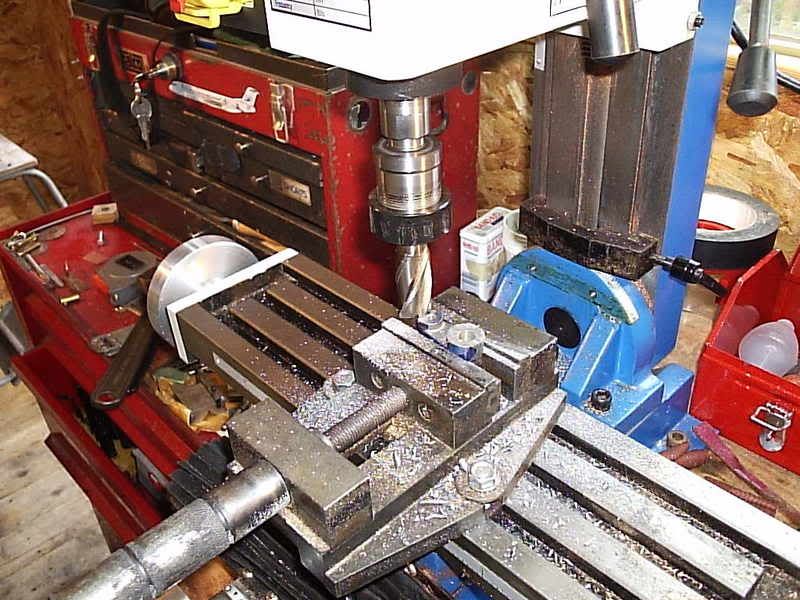

For those interested here is my lathe as it is at the moment.

The faceplate, 4 jaw chuck and toolbox resting on the stand

The tailstock, travelling and fixed steady

I'm wondering how much space everyone leaves around their lathe as obviously space is precious in a small workshop but proper access around the lathe is important too.

I was thinking of leaving a gap from the gearbox to the wall equal to the size of the gearbox cover swinging out plus about 20cm, about 45cm out from the wall and around 50cm clear from the end of the lathe.

Does this seem enough space or should I leave more?

For those interested here is my lathe as it is at the moment.

The faceplate, 4 jaw chuck and toolbox resting on the stand

The tailstock, travelling and fixed steady