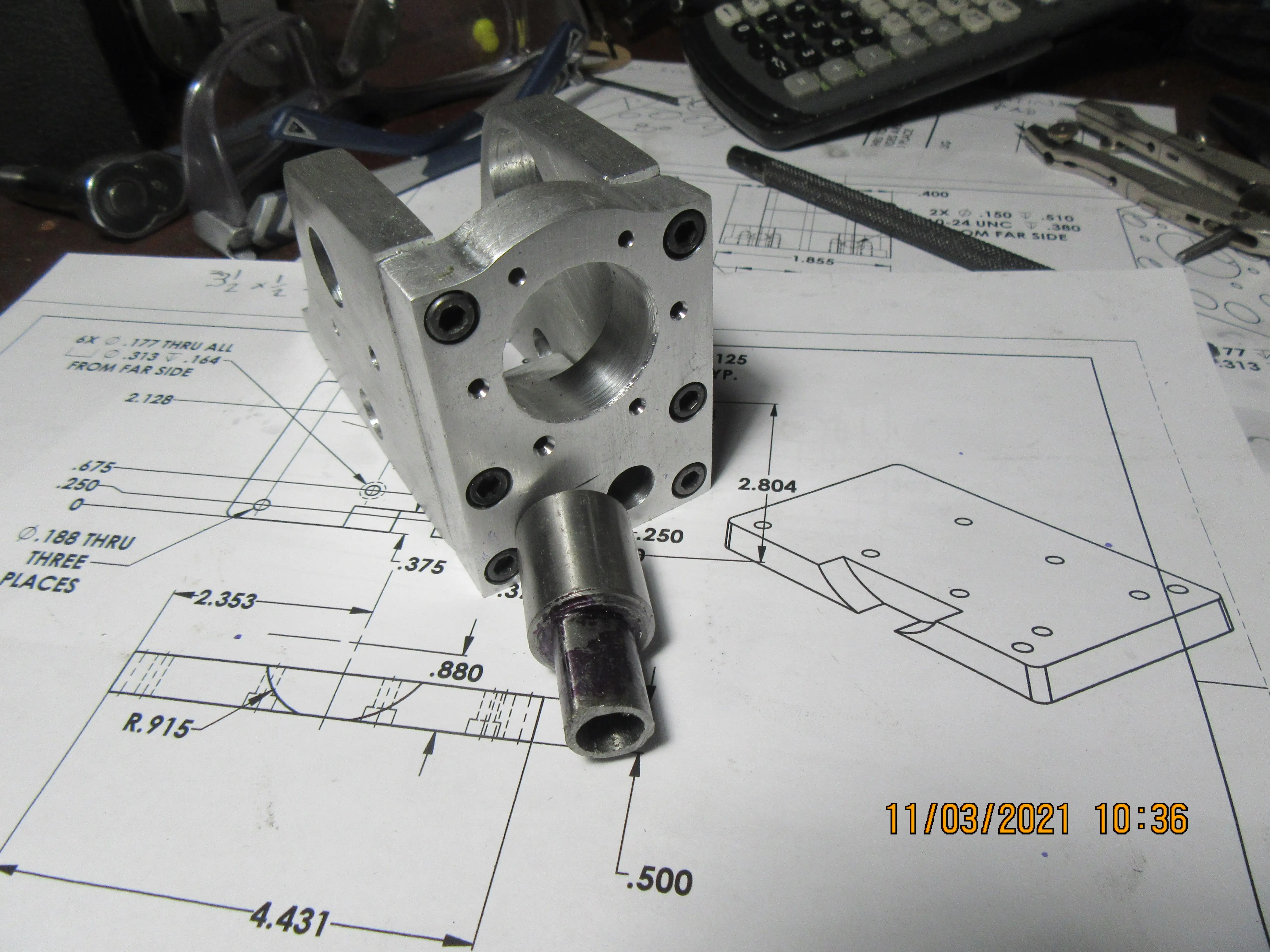

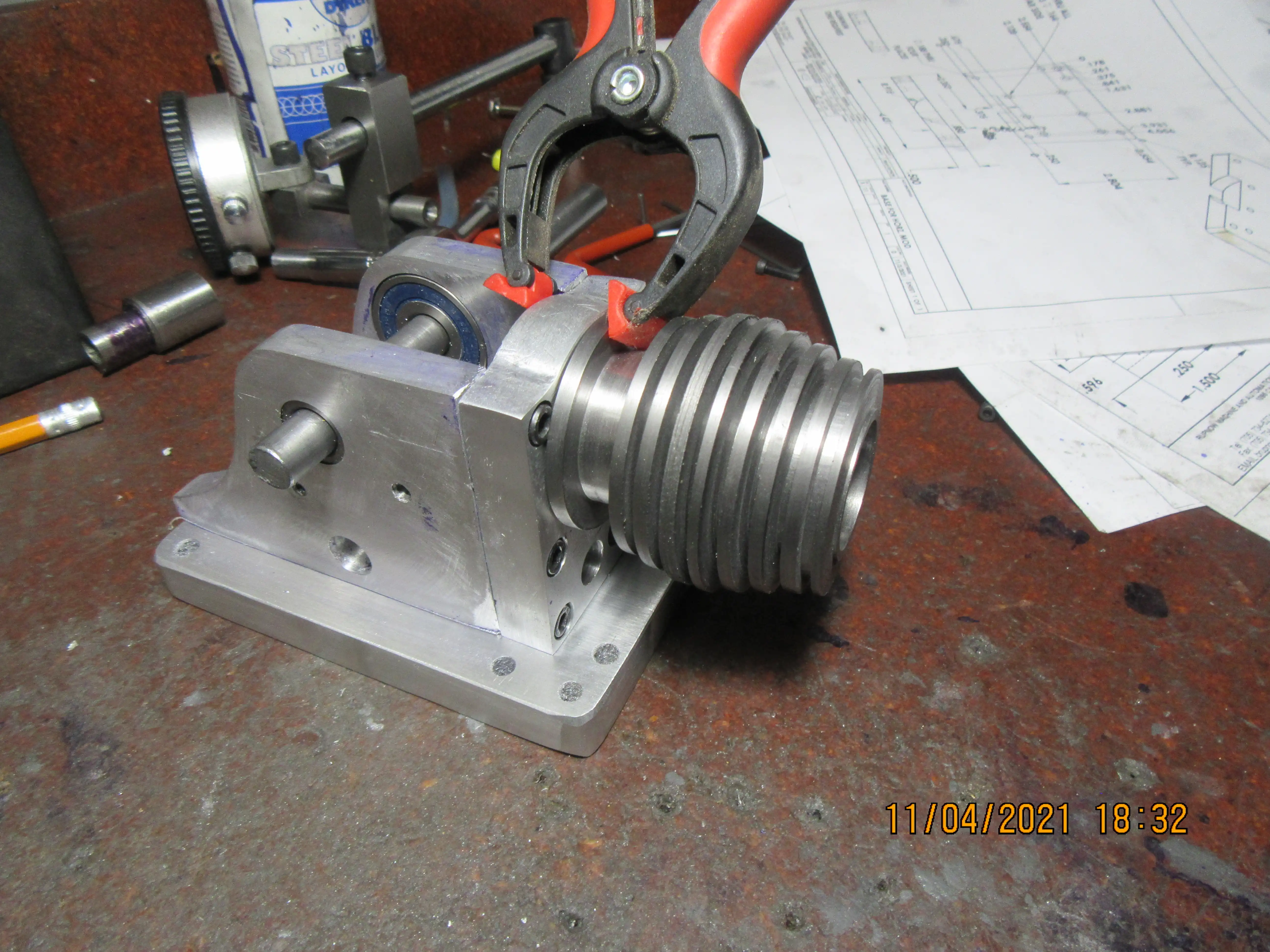

I had a stroke of good luck this morning. After tapping something like 20 holes, and assembling things, I discovered a length of 01 steel with two cams cut on it. The last time I set up to cut cams I decided to cut over-length while I was in the set-up for use on a potential future engine. The future has arrived!!!