- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

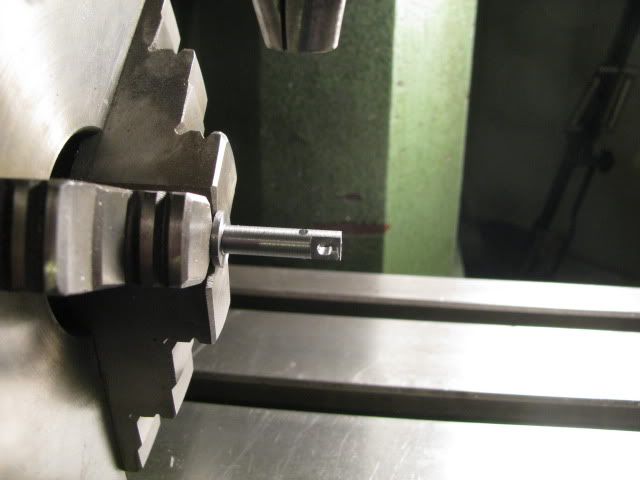

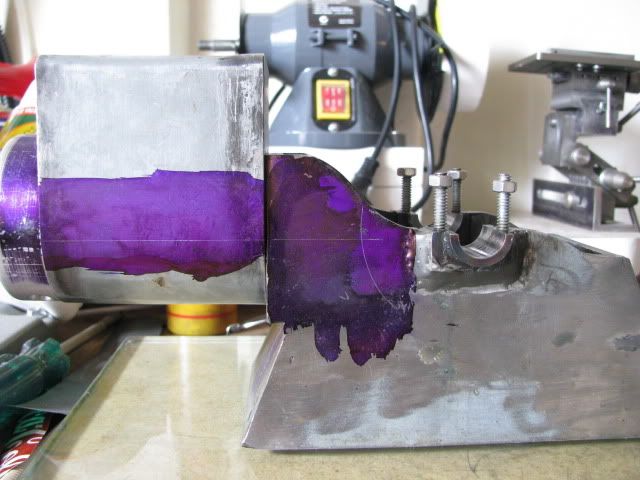

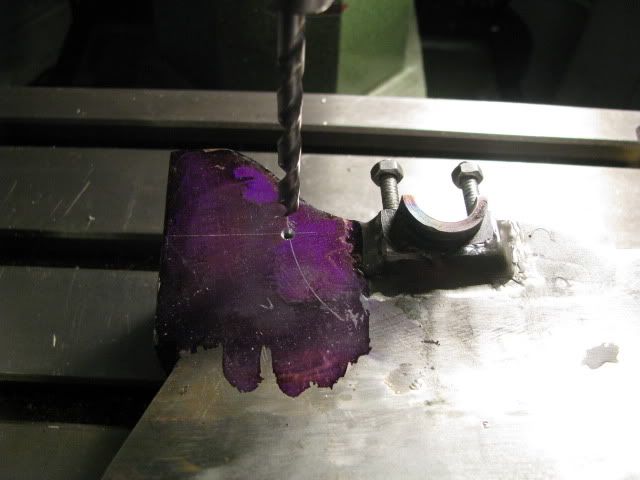

Thanks for the lesson, Bob. Now I know the first step in making a boring bar cutter. What's next?

Jerry

Jerry

Captain Jerry said:Thanks for the lesson, Bob. Now I know the first step in making a boring bar cutter. What's next?

Jerry

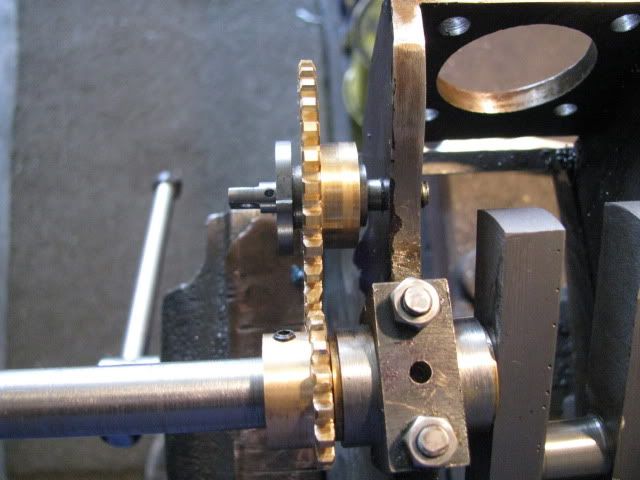

arnoldb said:And I saw another tool for my to-do list :

Enter your email address to join: