RobWilson said:The True North :big: :hDe:

but, Maryak ........ sincere apologies for straying off topic (but it was Rob's fault really) ............

CC

RobWilson said:The True North :big: :hDe:

gjn said:If you need a hand at any stage just yell out, I have MIG, Arc & Oxy and 30+ years of welding behind me and am just up in the hills.

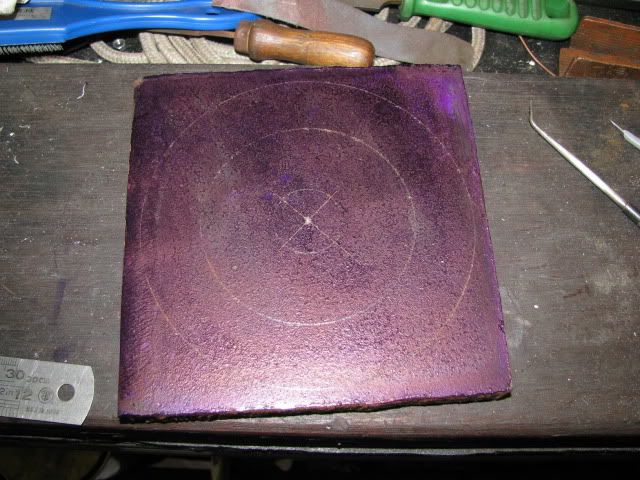

GailInNM said:Really looking good Bob.

Your techniques are quite different from mine in many cases, so I have learned a lot from your threads.

Maryak said:As a born in Lancashire lad I do have some idea of the "True North"

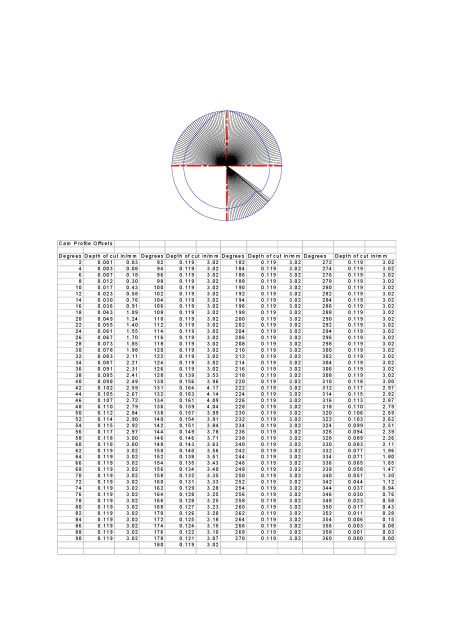

Maryak said:Now all I hope I have to hope for is the concentration powers to be able to make 181 successful cuts as per the spread sheet.

Best Regards

Bob

Enter your email address to join: