Hi folks,

It's been a while since I've posted to the forum. I am still saving for the purchase of a mill and a lathe so in the meantime I am trying to keep byself busy with Solidworks. I hope somebody can help with the following...

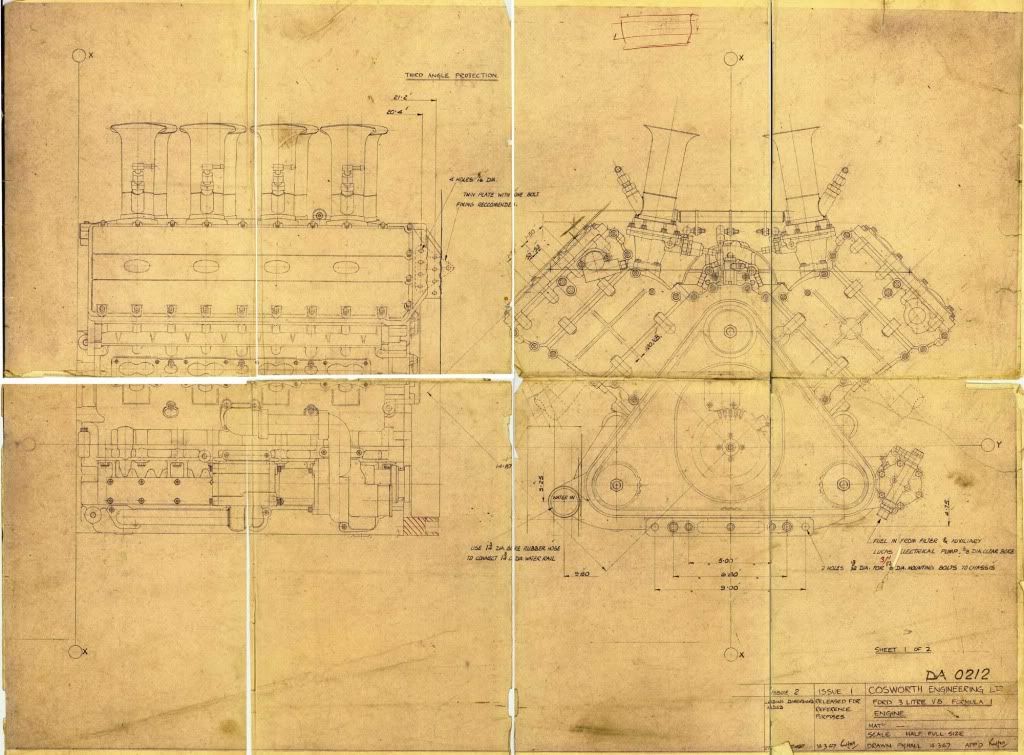

I've got the following information on the Cosworth DFV engine from historicengines.com :

[size=10pt]Crankcase:

Description: 90° V8 crankcase and cylinders cast together in aluminum. Wet cast iron cylinder liners sealed with O-rings. Steel,

coated iron, and nikasil alloy liners were also tried. Nikasil alloy liners saved 8 lb in overall engine weight, and were standard by

1983.

Weight (with clutch): 370 lb / 168 kg

Overall width: 27.0" (686 mm)

Overall length: 21.5" (545 mm)

Bore: 3.373" / 85.674 mm

Stroke: 2.555" / 64.8 mm

Bore spacing: 4.100" / 104.1 mm

Deck height: 6.505" / 165.2 mm (crankshaft centerline to deck surface)

Crankshaft height: 5.23" / 132.8 mm (crankshaft centerline to external sump bottom)

Cylinder stagger: 0.375" / 9.5 mm (left ahead of right)

Materials: Cast aluminum block and head, forged steel crank and rods (earliest DFV cranks were billet), forged aluminum pistons,

cast magnesium covers.

Firing order: 1-8-3-6-4-5-2-7

Compression ratio: 11.0:1 (approx.)

Fuel: 101 octane (M.M. - motor method) minimum

Rotation: clockwise when viewing front of engine

Crankshaft:

Description: single plane ("flat") common throw (2 rods per crank pin, no offset), forged nitrided steel (earliest cranks were billet

steel), 5 main bearing crankshaft, hollow crank pins, weight 32 lbs / 14.5 kg, thrust taken on #3 main bearing, 8 bolts on flywheel

flange.

Main journal diameter: 2.3755" to 2.3750" / 60.3 mm

Rod bearing diameter: 1.9370 to 1.9375" / 49.2 mm (same as Cosworth FVA: Bearing is Cosworth part number FA0067)

Connecting rod journal diameter: 1.9375" / 1.9370"

Crankshaft: End float: 0.004" / 0.009"

Connecting rod side clearance (big end): 0.006" / 0.012"

Piston :

Description: forged aluminum, 4 valve notches. Full floating wrist pin.

Piston compression height: 1.469 / 37.3 mm

Weight: ~328 grams (with rings, without pin)

Ring width:

top: 0.0315"/0.80 mm

middle: 0.0410"/1.04 mm

oil: 0.160"/4.06 mm

Piston ring gap (all rings): 0.017" to 0.022"

Connecting rod:

Description: forged steel, H-beam, fully machined connecting rods.

Bolts: 3/8" UNF

Connecting rod length: 5.23" (132.842 mm)

Wrist Pin length: 2.500" (63.5 mm)

Wrist pin diameter: 0.812" (20.638 mm)

Wrist pin end float: 0.000" ± 0.001" (retained by clips)

Rod/Stroke ratio: 2.05[/size]

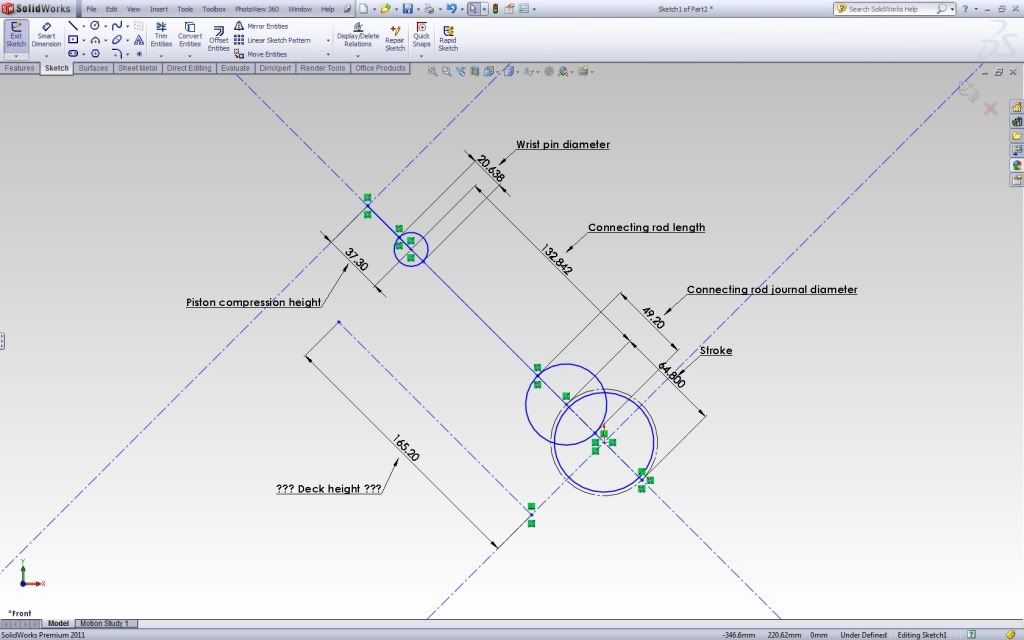

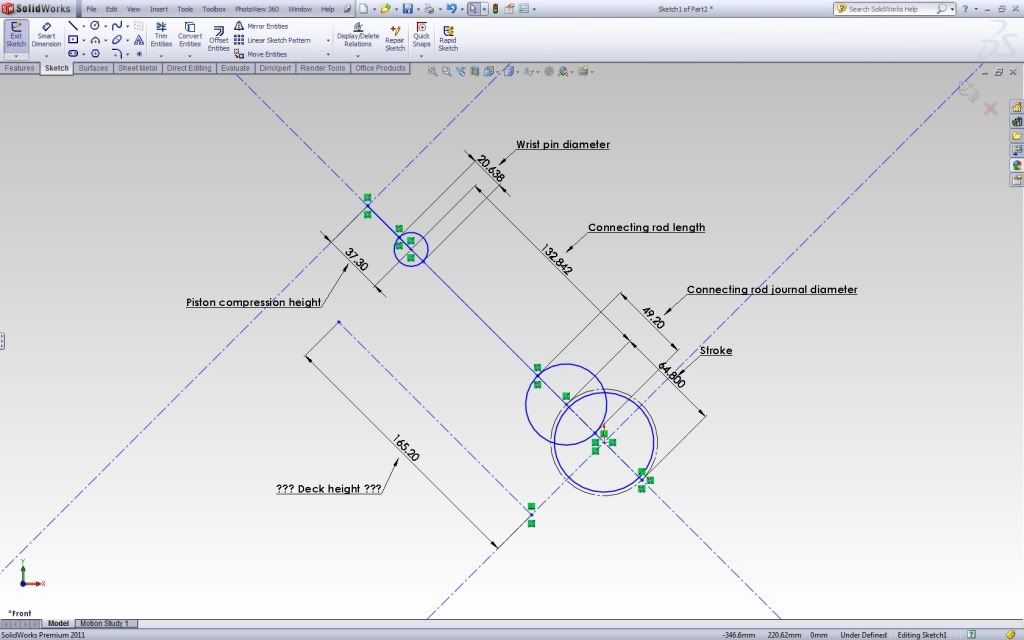

I am attempting to begin modelling in solidworks but I think I am probably going wrong somewhere. Please bear with me as I am still getting my head around a lot of engine terminology. In the following picture I think I have put in all the dimensions properly (I think) but if you look at the Deck Height it does not even clear the center of the wrist pin diameter:

I was not sure about what some terms such as deck height and compression height referred to so I have been using these diagrams that I found online:

The distance the deck height seems short by is curiously close to the dimension for the piston compression height. Anybody any pointers on where I could be going wrong? ???

It's been a while since I've posted to the forum. I am still saving for the purchase of a mill and a lathe so in the meantime I am trying to keep byself busy with Solidworks. I hope somebody can help with the following...

I've got the following information on the Cosworth DFV engine from historicengines.com :

[size=10pt]Crankcase:

Description: 90° V8 crankcase and cylinders cast together in aluminum. Wet cast iron cylinder liners sealed with O-rings. Steel,

coated iron, and nikasil alloy liners were also tried. Nikasil alloy liners saved 8 lb in overall engine weight, and were standard by

1983.

Weight (with clutch): 370 lb / 168 kg

Overall width: 27.0" (686 mm)

Overall length: 21.5" (545 mm)

Bore: 3.373" / 85.674 mm

Stroke: 2.555" / 64.8 mm

Bore spacing: 4.100" / 104.1 mm

Deck height: 6.505" / 165.2 mm (crankshaft centerline to deck surface)

Crankshaft height: 5.23" / 132.8 mm (crankshaft centerline to external sump bottom)

Cylinder stagger: 0.375" / 9.5 mm (left ahead of right)

Materials: Cast aluminum block and head, forged steel crank and rods (earliest DFV cranks were billet), forged aluminum pistons,

cast magnesium covers.

Firing order: 1-8-3-6-4-5-2-7

Compression ratio: 11.0:1 (approx.)

Fuel: 101 octane (M.M. - motor method) minimum

Rotation: clockwise when viewing front of engine

Crankshaft:

Description: single plane ("flat") common throw (2 rods per crank pin, no offset), forged nitrided steel (earliest cranks were billet

steel), 5 main bearing crankshaft, hollow crank pins, weight 32 lbs / 14.5 kg, thrust taken on #3 main bearing, 8 bolts on flywheel

flange.

Main journal diameter: 2.3755" to 2.3750" / 60.3 mm

Rod bearing diameter: 1.9370 to 1.9375" / 49.2 mm (same as Cosworth FVA: Bearing is Cosworth part number FA0067)

Connecting rod journal diameter: 1.9375" / 1.9370"

Crankshaft: End float: 0.004" / 0.009"

Connecting rod side clearance (big end): 0.006" / 0.012"

Piston :

Description: forged aluminum, 4 valve notches. Full floating wrist pin.

Piston compression height: 1.469 / 37.3 mm

Weight: ~328 grams (with rings, without pin)

Ring width:

top: 0.0315"/0.80 mm

middle: 0.0410"/1.04 mm

oil: 0.160"/4.06 mm

Piston ring gap (all rings): 0.017" to 0.022"

Connecting rod:

Description: forged steel, H-beam, fully machined connecting rods.

Bolts: 3/8" UNF

Connecting rod length: 5.23" (132.842 mm)

Wrist Pin length: 2.500" (63.5 mm)

Wrist pin diameter: 0.812" (20.638 mm)

Wrist pin end float: 0.000" ± 0.001" (retained by clips)

Rod/Stroke ratio: 2.05[/size]

I am attempting to begin modelling in solidworks but I think I am probably going wrong somewhere. Please bear with me as I am still getting my head around a lot of engine terminology. In the following picture I think I have put in all the dimensions properly (I think) but if you look at the Deck Height it does not even clear the center of the wrist pin diameter:

I was not sure about what some terms such as deck height and compression height referred to so I have been using these diagrams that I found online:

The distance the deck height seems short by is curiously close to the dimension for the piston compression height. Anybody any pointers on where I could be going wrong? ???