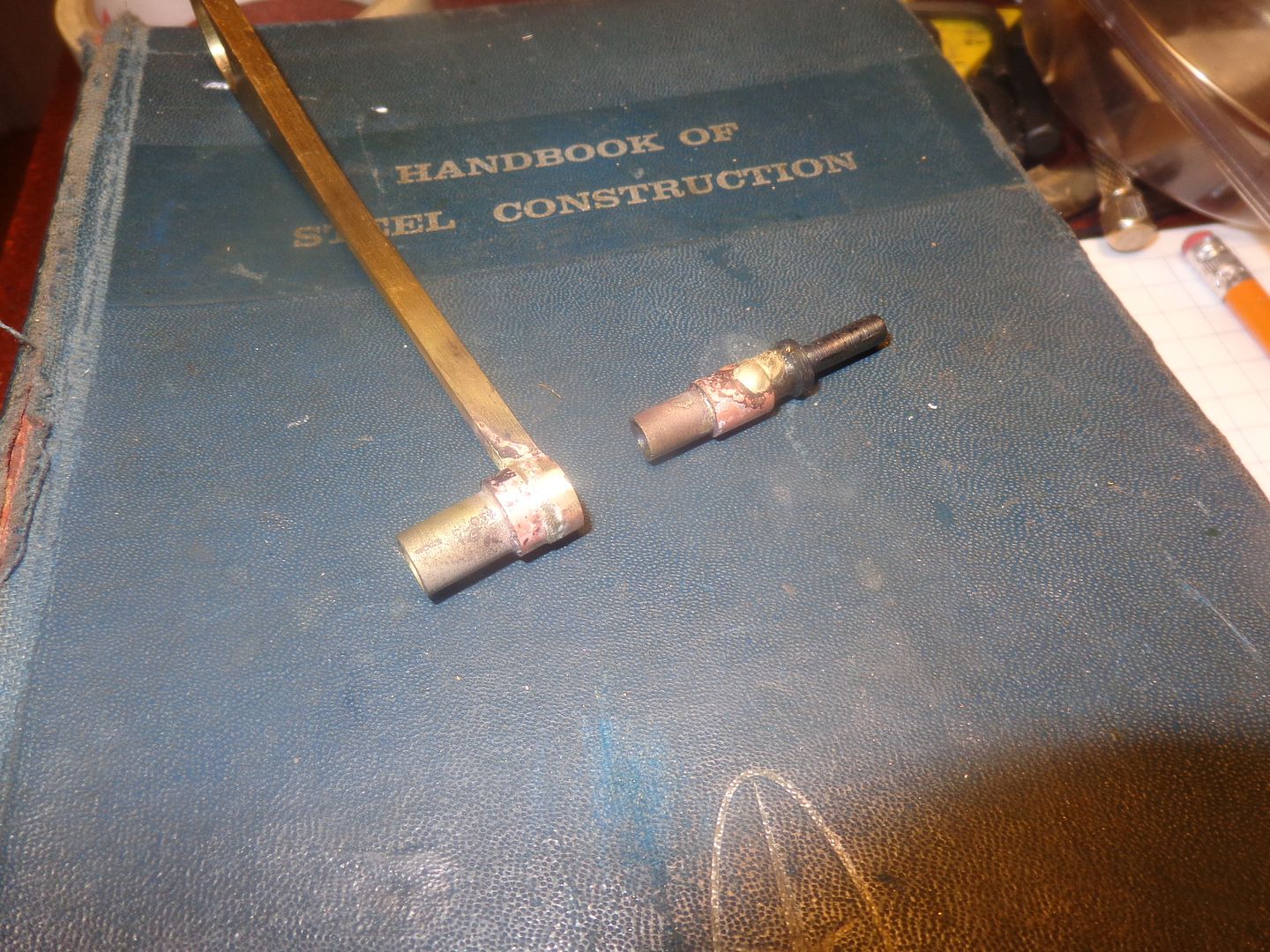

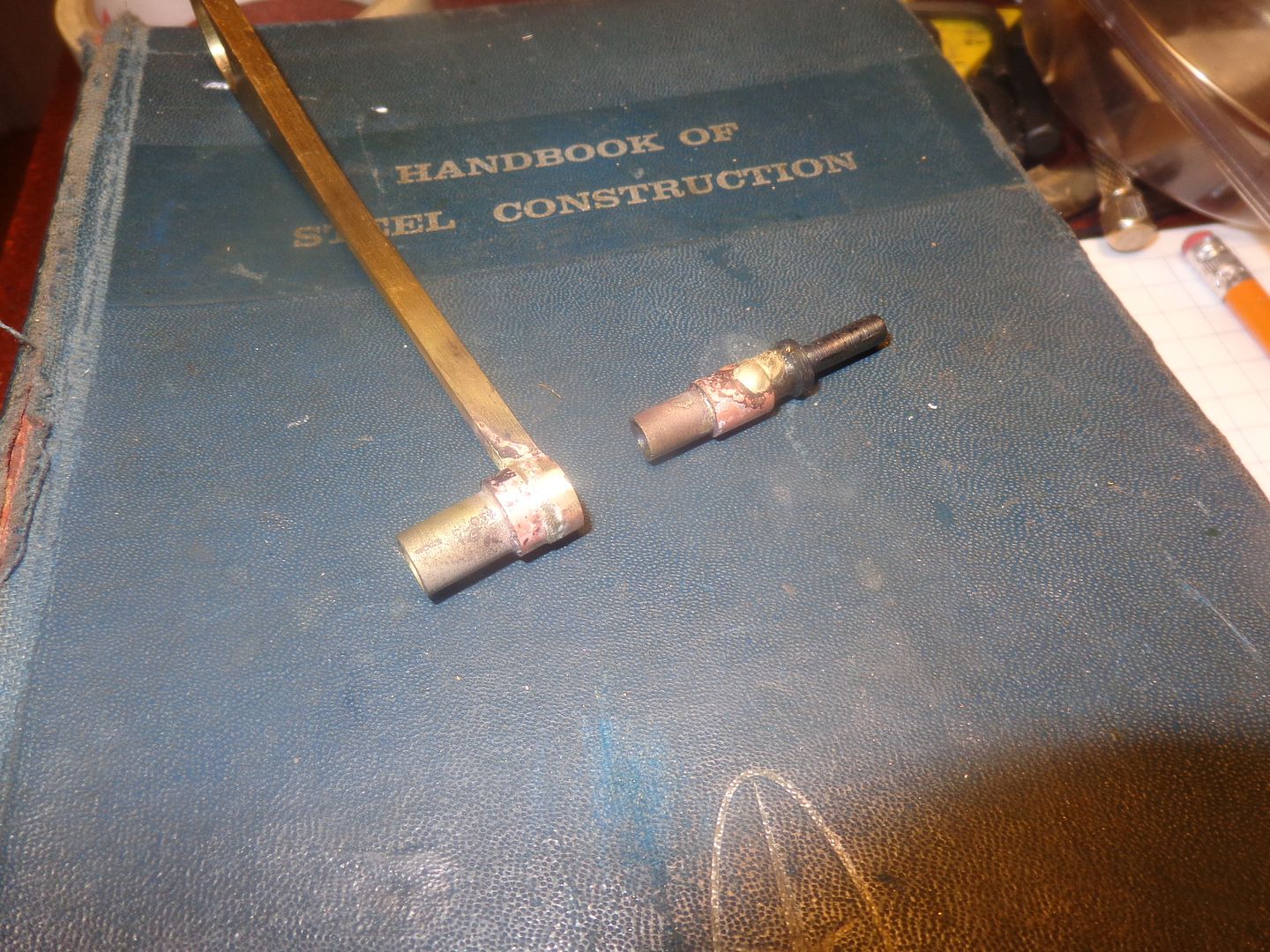

Whenever I silver solder brass parts, I use a paste flux recommended by the silver solder manufacturer.It is made by Harris, and is simply called "StaySilv white brazing flux". It works great but wherever it melts and runs to as a result of heat from the torch, which liquifies it, it stains the brass red. Not a vivid dark red, but still red enough to be quite visible. The attached picture shows two test parts immediately after silver soldering them together, and the reddish color around the soldered area is quite visible.

Last edited: