You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Comber / Coomber build

- Thread starter arnoldb

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Arnold - another superlatively documented build and a great runner - thanks for the trip.

Re Chuck's suggestion of two cylinders ? I presume two side by side ar 90° to each other with two cam rings etc. etc.

Any comments ?

Dammit - my to do pile keeps growing an awful lot faster than my done list.

I stocked up on Windhoek to tide me over the festive season before you guys drink it all like you did last year.

Regards,

Ken

Re Chuck's suggestion of two cylinders ? I presume two side by side ar 90° to each other with two cam rings etc. etc.

Any comments ?

Dammit - my to do pile keeps growing an awful lot faster than my done list.

I stocked up on Windhoek to tide me over the festive season before you guys drink it all like you did last year.

Regards,

Ken

arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

Kevin, thank you  - I don't know about workmanship; more like tons of blind luck and a bit of hard work :big:

- I don't know about workmanship; more like tons of blind luck and a bit of hard work :big:

Baie dankie Andrew ;D ; mailed sis a photo of it; she's driving down from the Caprivi in two weeks for some business here in Windhoek... 2800km round trip to fetch an engine :big:

Thanks Jim Any progress on the boiler ?

Any progress on the boiler ?

Les, thanks - Unfortunately I can't send the background; I can take a nice big photo though that you can stick on the windows to block out the miserable weather ;D - Sounds like the winter's going to be a bad 'un in the UK again this year. Today's a bit wet with a thunder storm here, but us Namibians really appreciate a bit of rain

- Unfortunately I can't send the background; I can take a nice big photo though that you can stick on the windows to block out the miserable weather ;D - Sounds like the winter's going to be a bad 'un in the UK again this year. Today's a bit wet with a thunder storm here, but us Namibians really appreciate a bit of rain

Thanks Ken. :big: Good idea to stock up; the Windhoek is now getting exported to the UK and about six new African destinations as well. I drive past the Namibian Breweries nearly every day, and it's amazing how much they've grown in the last couple of years. About two months ago, they did a major upgrade to the plant to increase brewing capacity to keep up with demand.

As to comments...

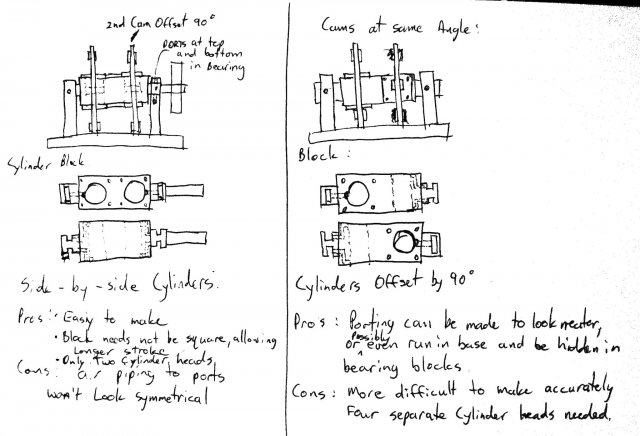

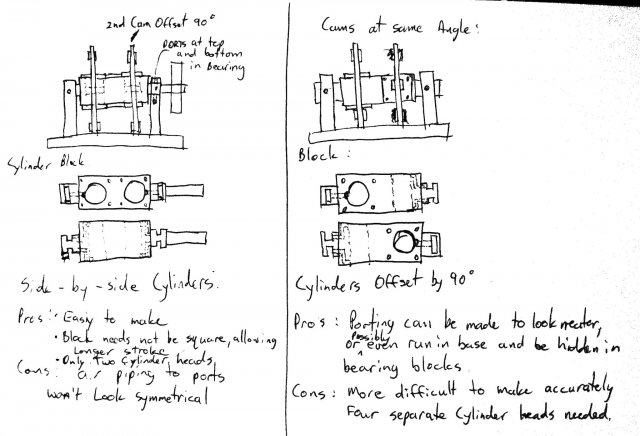

I did a very quick C-o-C of two possibilities (you can click on it for a larger picture):

Right, now we'll wait a bit for everyone to get over the laughing fit - I did say its C-o-C after all ;D

......

What I meant in my earlier reply to Chuck was the side-by-side ( inline is a better term) as shown on the left. One cam have to be rotated 90 degrees from the other, which means the air ports in the second bearing column also have to be offset by 90 degrees.

I think what you're thinking of is what I sketched on the right, with the cylinders offset by 90 degrees and the cams in the same orientation.

I don't think one can get away with using just one cam ring - the cam followers would have to have additional "L" sections which will cause binding, as they will rotate on the cylinder axis and basically pinch up on the cam, unless one add crosshead guides - which should look really cool .

.

Like I mentioned in the earlier post, the valving will require the most thought, and I'm having trouble visualizing it...

:idea: I just had a thought though :big: - I actually HAVE two Coombers available to me for a few days; I think I'll try and couple their drive shafts at 90 degrees and see what the porting would have to be like... Give me a day or so and I'll post feedback Thm:

A twin cylinder would not require a flywheel, except for really slow running. The single has two power strokes per revolution and a twin offset by 90 degrees would be self-starting to boot.

While I spent a lot of time on the cam ring, I think it may just be possible to make a double cylinder a runner with a plain circle as cam. The cam on this one I built is only about 2mm out of a true circle, and the cam will get more pronounced with a longer stroke. I won't put the family jewels on a block for a plain circle cam though

Regards, Arnold

Baie dankie Andrew ;D ; mailed sis a photo of it; she's driving down from the Caprivi in two weeks for some business here in Windhoek... 2800km round trip to fetch an engine :big:

Thanks Jim

Les, thanks

Thanks Ken. :big: Good idea to stock up; the Windhoek is now getting exported to the UK and about six new African destinations as well. I drive past the Namibian Breweries nearly every day, and it's amazing how much they've grown in the last couple of years. About two months ago, they did a major upgrade to the plant to increase brewing capacity to keep up with demand.

As to comments...

I did a very quick C-o-C of two possibilities (you can click on it for a larger picture):

Right, now we'll wait a bit for everyone to get over the laughing fit - I did say its C-o-C after all ;D

......

What I meant in my earlier reply to Chuck was the side-by-side ( inline is a better term) as shown on the left. One cam have to be rotated 90 degrees from the other, which means the air ports in the second bearing column also have to be offset by 90 degrees.

I think what you're thinking of is what I sketched on the right, with the cylinders offset by 90 degrees and the cams in the same orientation.

I don't think one can get away with using just one cam ring - the cam followers would have to have additional "L" sections which will cause binding, as they will rotate on the cylinder axis and basically pinch up on the cam, unless one add crosshead guides - which should look really cool

Like I mentioned in the earlier post, the valving will require the most thought, and I'm having trouble visualizing it...

:idea: I just had a thought though :big: - I actually HAVE two Coombers available to me for a few days; I think I'll try and couple their drive shafts at 90 degrees and see what the porting would have to be like... Give me a day or so and I'll post feedback Thm:

A twin cylinder would not require a flywheel, except for really slow running. The single has two power strokes per revolution and a twin offset by 90 degrees would be self-starting to boot.

While I spent a lot of time on the cam ring, I think it may just be possible to make a double cylinder a runner with a plain circle as cam. The cam on this one I built is only about 2mm out of a true circle, and the cam will get more pronounced with a longer stroke. I won't put the family jewels on a block for a plain circle cam though

Regards, Arnold

It never crossed my mind to offset the cams 90° - I like your thinking.

Ken

Ken

arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

A bit of a follow-up for Ken

I did some tests with the two Coombers this afternoon. They're not exactly a matched pair, as the one is a bit smaller than the other, but the information should be good.

For starters, I connected both engines along the crank shaft with a bit of rubber pipe - with the cylinders offset at 90 degrees to each other and the cams in the same orientation - and checked which way they wanted to run. Had to swap the porting around on the small engine; it turns out if connected like this, they want the intake port on the same side, which makes sense in retrospect:

[ame]http://www.youtube.com/watch?v=DlUrpPfsj90[/ame]

To test for the cam offset by 90 degrees and with the cylinders in-line, I set up like this:

[ame]http://www.youtube.com/watch?v=W8yHks3FCPs[/ame]

Now it seems so simple; if one wants to use the offset cam method, the intake port must just follow in the same direction as the cam is rotated...

Self-starting proved a bit problematic; but that could be due to the small engine not having enough oomph to turn the bigger one. The flexible "shaft" also caused some additional friction on the engines as it put extra load on the bearings, and also introduced a bit of axial flex.

I feel like a regular dunce now having seen what I was not able to think through, but anyway, there it is - hope it's useful for someone

At least I had the fun of seeing two Coombers running in unison :big:

Regards, Arnold

I did some tests with the two Coombers this afternoon. They're not exactly a matched pair, as the one is a bit smaller than the other, but the information should be good.

For starters, I connected both engines along the crank shaft with a bit of rubber pipe - with the cylinders offset at 90 degrees to each other and the cams in the same orientation - and checked which way they wanted to run. Had to swap the porting around on the small engine; it turns out if connected like this, they want the intake port on the same side, which makes sense in retrospect:

[ame]http://www.youtube.com/watch?v=DlUrpPfsj90[/ame]

To test for the cam offset by 90 degrees and with the cylinders in-line, I set up like this:

[ame]http://www.youtube.com/watch?v=W8yHks3FCPs[/ame]

Now it seems so simple; if one wants to use the offset cam method, the intake port must just follow in the same direction as the cam is rotated...

Self-starting proved a bit problematic; but that could be due to the small engine not having enough oomph to turn the bigger one. The flexible "shaft" also caused some additional friction on the engines as it put extra load on the bearings, and also introduced a bit of axial flex.

I feel like a regular dunce now having seen what I was not able to think through, but anyway, there it is - hope it's useful for someone

At least I had the fun of seeing two Coombers running in unison :big:

Regards, Arnold

Thanks Arnold, that helps crystalise it in my mind.

I'm also having trouble bending my mind around it - one moment I'm convinced it won't self start then a bit more thinking convinces me it will - I'm currently in the "it will" mode.

Like I said - one more thing added to the "to do" list.

Ken

I'm also having trouble bending my mind around it - one moment I'm convinced it won't self start then a bit more thinking convinces me it will - I'm currently in the "it will" mode.

Like I said - one more thing added to the "to do" list.

Ken

peepfrance

Member

- Joined

- Aug 14, 2010

- Messages

- 6

- Reaction score

- 0

I would love to build this engine but does any one know how to construct the spread sheet for the cam profile.

Pete

Pete

peepfrance

Member

- Joined

- Aug 14, 2010

- Messages

- 6

- Reaction score

- 0

Sorry all, just read the group build thread and found Gails spreadsheet, many thanks for uploading.

Congratulations to arnoldb for an excellent build

Pete

Congratulations to arnoldb for an excellent build

Pete

Similar threads

- Replies

- 3

- Views

- 1K

Latest posts

-

-

-

-

-

-

-

-

Stuart S50 - Replacing mild steel shafts with stainless steel shafts.

- Latest: Jens Eirik Skogstad