Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

I've never made an eccentric and hub combination using a 4 jaw chuck. But motivated by more than one description of how to do it on this forum I gave it a try.

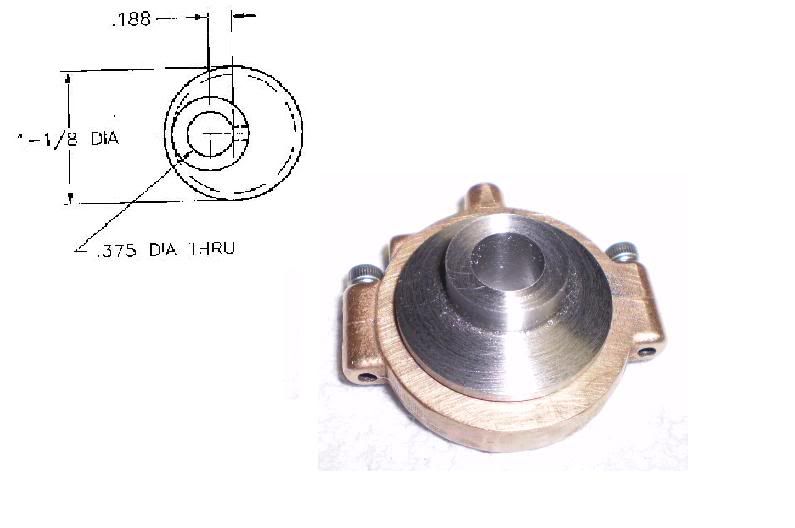

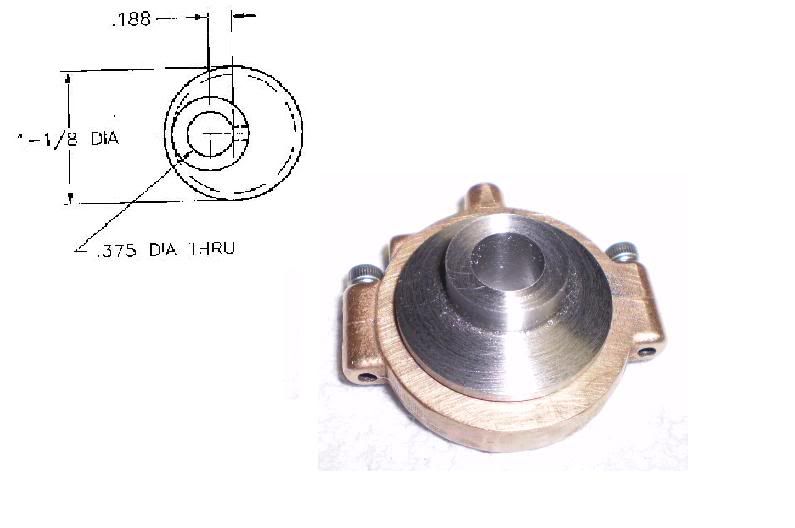

Here's the eccentric assembly as finished next to a drawing of one aspect of the part.

The fit is as good as I could hope for, the eccentric rides snugly in the hub. I was pretty happy with the result. Decided to measure the distance between the edge of the through hole and the rim of the hub. Oops! Thats not right, Im getting 0.282 instead of 0.188. ??? ???

Oh yeah, an offset 0.188 means I have to actually get an indicator range of 0.375 between the opposing jaws. :'( :'( :'(

Anyone making a steam engine with a 0.094 eccentric offset? the hub is yours for free.

Cheers,

Phil

Here's the eccentric assembly as finished next to a drawing of one aspect of the part.

The fit is as good as I could hope for, the eccentric rides snugly in the hub. I was pretty happy with the result. Decided to measure the distance between the edge of the through hole and the rim of the hub. Oops! Thats not right, Im getting 0.282 instead of 0.188. ??? ???

Oh yeah, an offset 0.188 means I have to actually get an indicator range of 0.375 between the opposing jaws. :'( :'( :'(

Anyone making a steam engine with a 0.094 eccentric offset? the hub is yours for free.

Cheers,

Phil