hi every one i am starting to build a engine based on fords first engine. i'm useing 1 inch pipe fittings so i will have a 1 inch bore and i'm thing of about 1 1/2 inch stroke with about a 10 inch flywheel and 1/2 inch fittings for the valves. now to my question what size and length should i make the con rod? any help and tips would be great. i will post some pics when i get started thanks cam

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

fords first engine

- Thread starter cam081

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

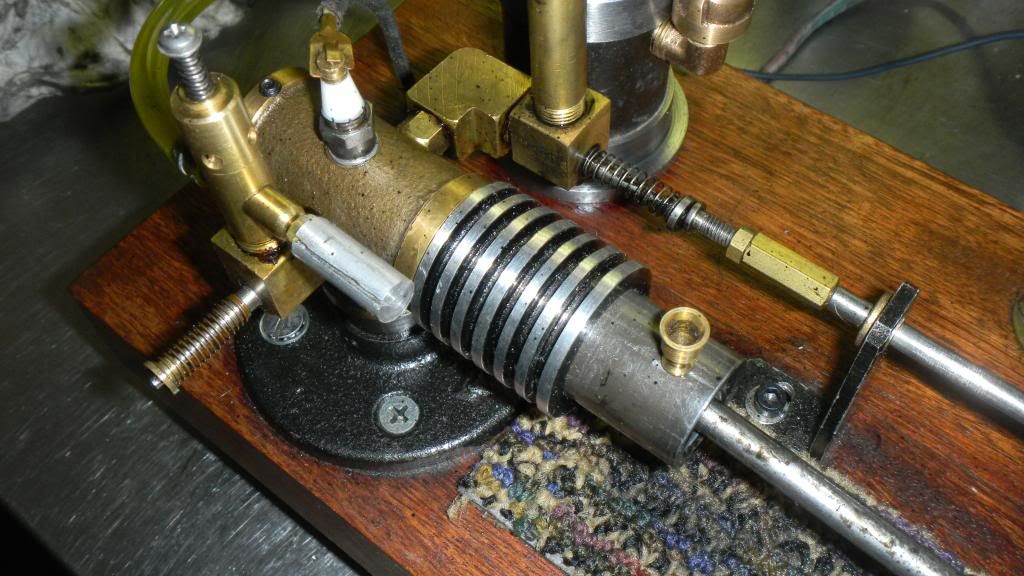

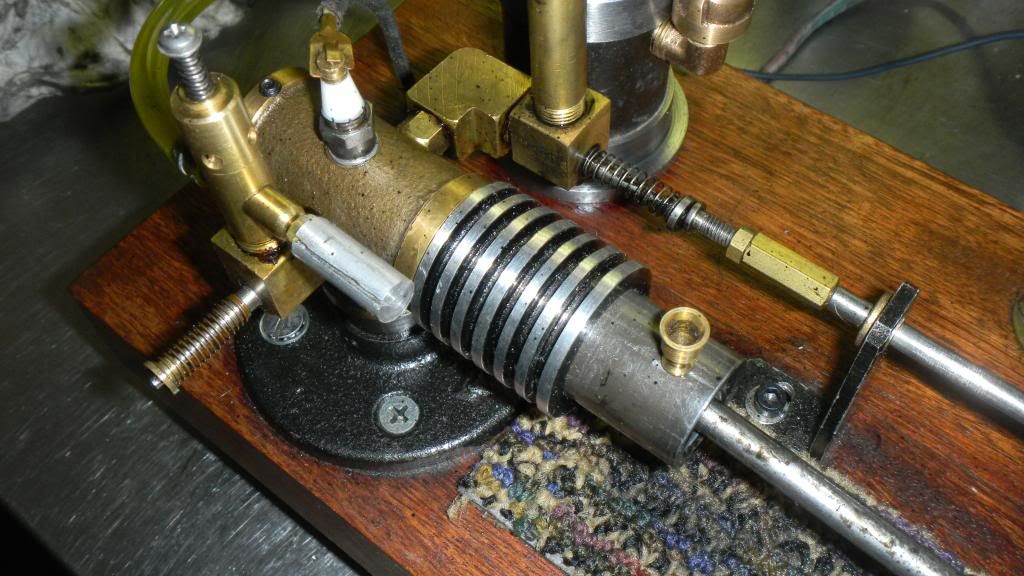

I built an engine based on Ford's first engine. I used plumbing parts for the cylinder and stand. Mine has a 13/16" bore, a 1 3/4" stroke, and a 7 1/4" flywheel. My connecting rod is about 9 inches long. It could have been shorter, but I like the longer look.

Here's a link to my build thread on this forum...

http://www.homemodelenginemachinist.com/f31/plumbing-parts-engine-5675/index22.html

Here's a video of it running...

[ame]http://www.youtube.com/watch?v=y_PFz3hfuKI[/ame]

Made a cast iron cylinder liner instead of of using plain pipe. I also used a vapor carburetor rather than Ford's drip carburetor. And I used conventional intake and exhaust valves.

Chuck

Here's a link to my build thread on this forum...

http://www.homemodelenginemachinist.com/f31/plumbing-parts-engine-5675/index22.html

Here's a video of it running...

[ame]http://www.youtube.com/watch?v=y_PFz3hfuKI[/ame]

Made a cast iron cylinder liner instead of of using plain pipe. I also used a vapor carburetor rather than Ford's drip carburetor. And I used conventional intake and exhaust valves.

Chuck

thanks chuck i am going to make mine water cooled as well. how long does your engine run befor it gets hot? i was thinking of setting mine up to rum on gas (propane) i would like to run mine much longer and with out having to baby it all the time. cam

- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

thanks chuck i am going to make mine water cooled as well. how long does your engine run befor it gets hot? i was thinking of setting mine up to rum on gas (propane) i would like to run mine much longer and with out having to baby it all the time. cam

It get's hot pretty quick, in under 5 minutes. But with the water cooling, it never overheats. A word of caution with propane... lubrication of the piston and cylinder can be a problem if you don't use liquid fuel with oil mixed in. Also, be sure you use a demand valve so if the engine quits while it's unattended, it won't allow propane to continue to flow.

Chuck

Generatorgus

Senior Member

- Joined

- Feb 25, 2010

- Messages

- 362

- Reaction score

- 166

My half scale runs quite hot. I added some cooling fins over the cylinder, seems to help a little.

Best thing I can do with it is to run it very rich.

I use WD in the coleman fuel and it seems the extra fuel helps but it slobbers some as witnessed in this pic.

I've run it continuously for hours, adding fuel while it's running and it's holding up nicely.

The O-ring takes a beating and I have to change it now and then, but that only takes a couple minutes.

All said it's a good runner.

GUS

Best thing I can do with it is to run it very rich.

I use WD in the coleman fuel and it seems the extra fuel helps but it slobbers some as witnessed in this pic.

I've run it continuously for hours, adding fuel while it's running and it's holding up nicely.

The O-ring takes a beating and I have to change it now and then, but that only takes a couple minutes.

All said it's a good runner.

GUS

You have to try "castor" oil. It mix perfectly with all kinds of fuell & lufribicates super. Also it don't burn & come back out the exhaust. So it take a lot of heat away.

So your nice engine will run a little bit cooler. Also Methanol as fuel will cool the engine. Put a amount of...let me say a 10% nitro....You have to richen the mixture on the carburettor. More fuell = cooling.

Ok,I don't know how to make a motor,because no education for a lathe & milling machine & learning all myself wit youtube & pictures , but I know how to keep a engine running.

Also , methanol have a very high octane , so you have less self-combustion. No more knocking.

I hope you understand a little bit from my bad english writing

So your nice engine will run a little bit cooler. Also Methanol as fuel will cool the engine. Put a amount of...let me say a 10% nitro....You have to richen the mixture on the carburettor. More fuell = cooling.

Ok,I don't know how to make a motor,because no education for a lathe & milling machine & learning all myself wit youtube & pictures , but I know how to keep a engine running.

Also , methanol have a very high octane , so you have less self-combustion. No more knocking.

I hope you understand a little bit from my bad english writing

Similar threads

- Replies

- 39

- Views

- 4K

- Replies

- 13

- Views

- 813