Chuck,

Here in the UK, because we have all the specialist sizes of threads already geared up for small pipe fittings (M.E., B.A.), we tend not to have the problems you do.

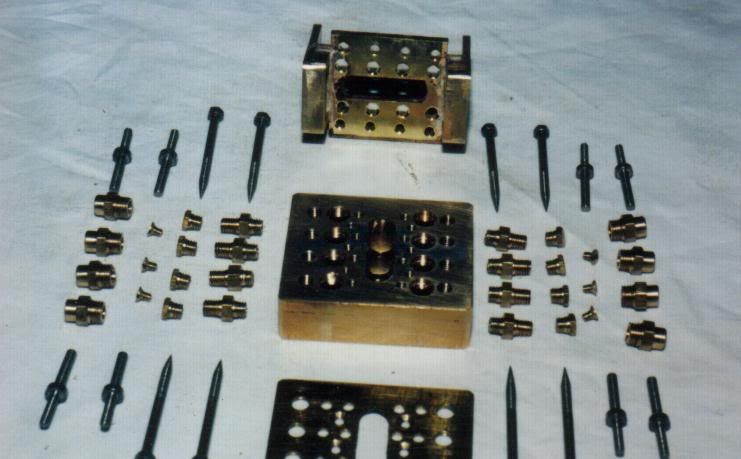

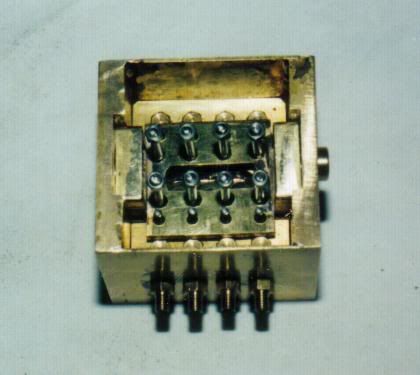

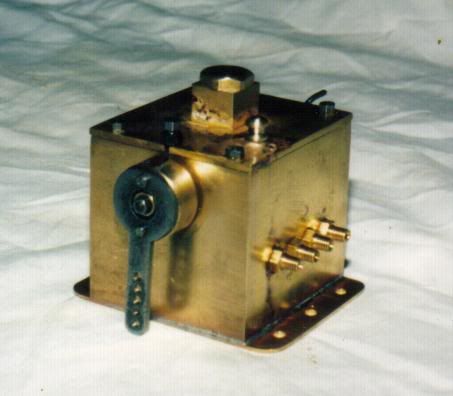

Below 1/8" pipe size, we tend to make our own, consisting of a component union with a 60 degree taper (I use a centre drill for making the internal taper), a coned ferrule that the pipe is silver soldered into and a nut for tightening it all together. Just smaller versions of the 1/8" size. You can buy some fitting for 3/32", but not everyone stocks them.

This shows the system we tend to use. Go to pipe nuts and ferrules and single pipe unions.

http://www.steamfittings.co.uk/asp/index.asp

This downloadable catalogue from Bruce Engineering is very interesting, and again, shows what is available commercially. Start at about page 40 for steam fittings.

http://www.pollymodelengineering.co.uk/sections/bruce-engineering/docs/cat_may10.pdf

These might give you a few ideas on the way to proceed.

John