This post will show the completion of the eccentric straps.

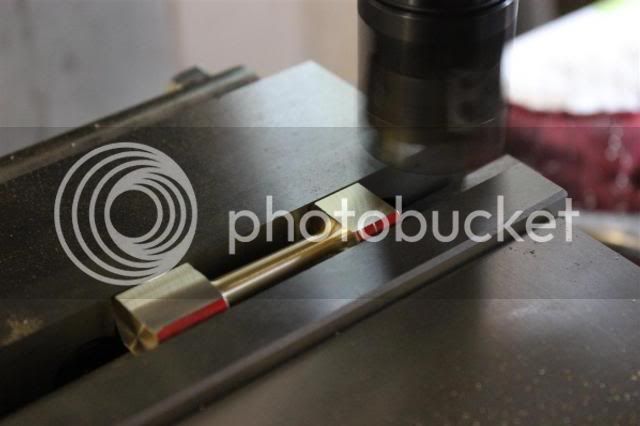

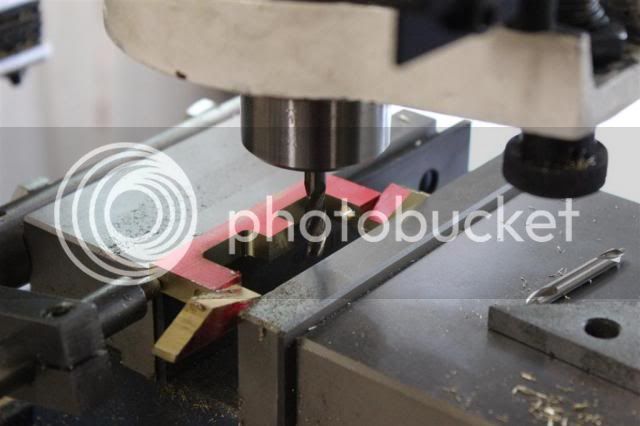

I start by boring the large end to final size.

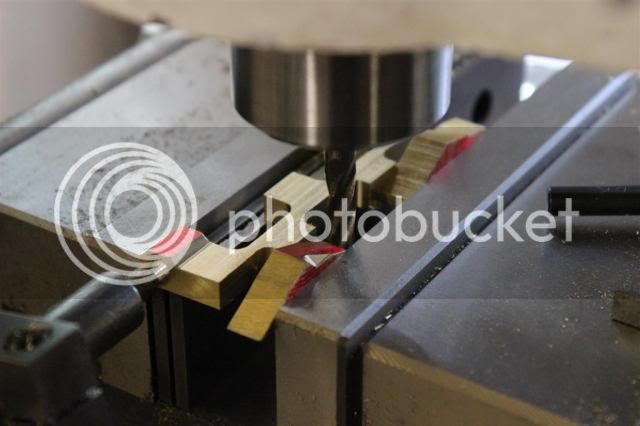

Then I thin the part to the largest thickness, which is the small end.

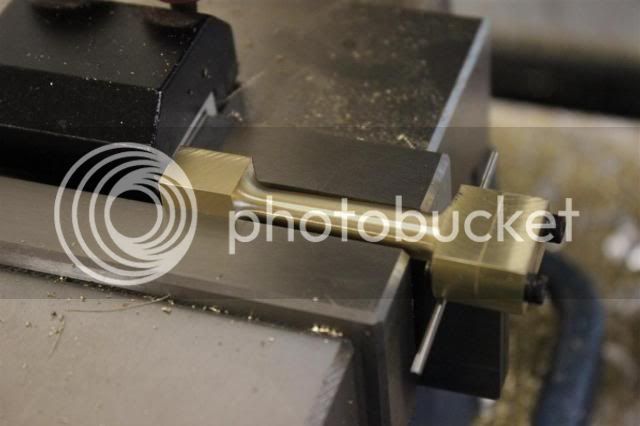

Then bring the large end to final thickness.

Then using a .125" saw I cut the slot.

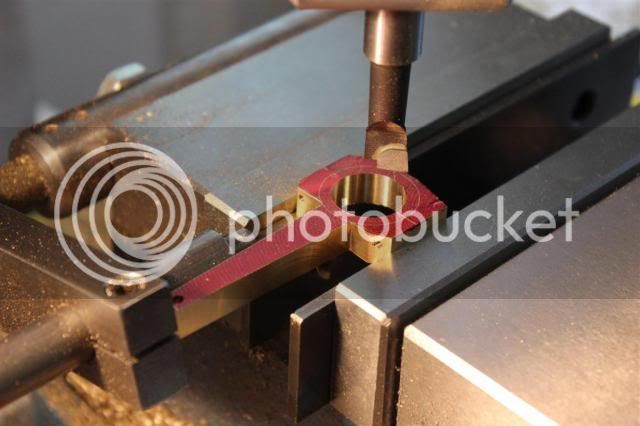

Then on to the rotary table to shape the upper part of the large end and bring the strap to final thickness.

Then using a ball endmill I radius the transition.

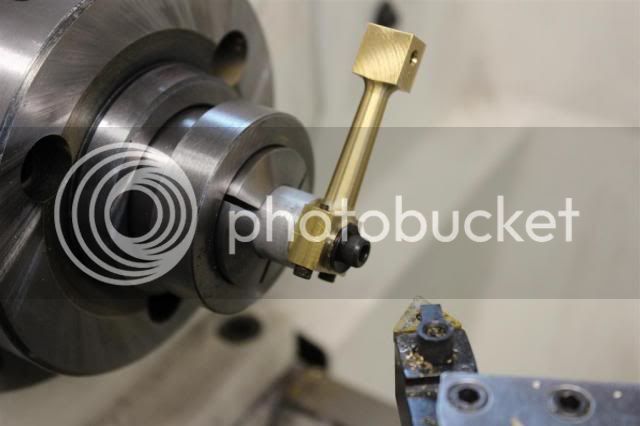

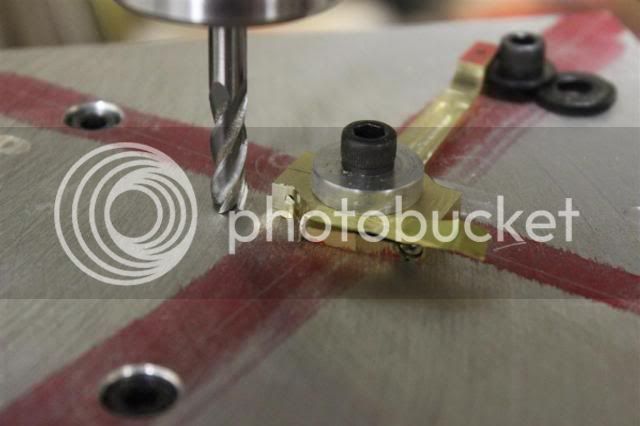

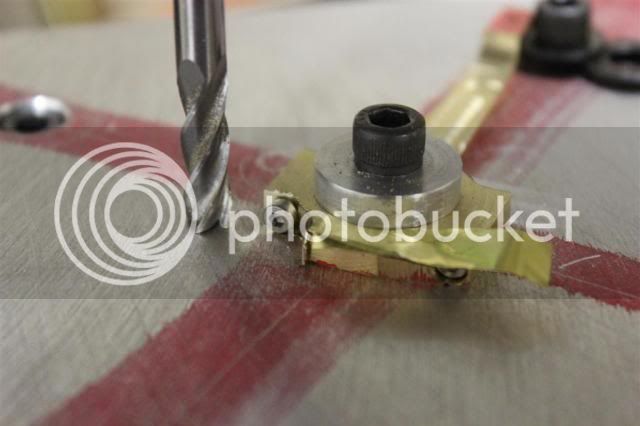

Now the worrisome part. I want to cut the profile on the lower half but I am concerned about the part jumping out the the fixture since I will be making a climb cut. What I did was to add a .002" shim under the clamp to make sure it was clamped securely and approached the cut from a direction to minimize the chance of the part coming loose.

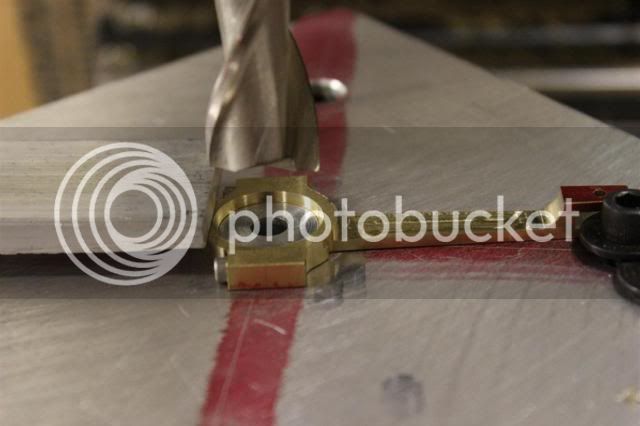

I left the screw in the other end.

Then I replaced the screw and removed the screw from the other end.

Then just made the cut in the normal way since I wasn't worried about the part coming loose cutting from this direction. There is a very small amount of material left at the bottom edge because I left the mill .002" above the table so as not to cut into it.

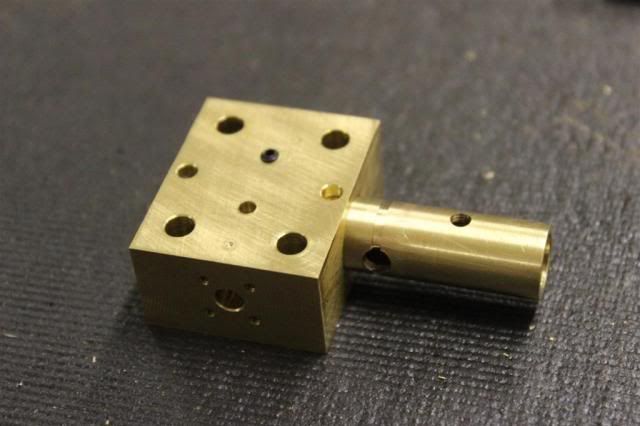

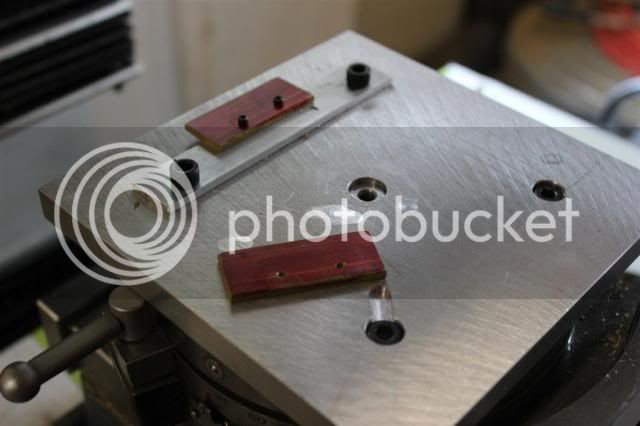

Then I used a endmill to create a counter bore on both sides to leave a "rib" in the middle. It looks like the usual way to make this is to cut a groove instead of a rib, but I figured it would be easier to cut the groove in the eccentric.

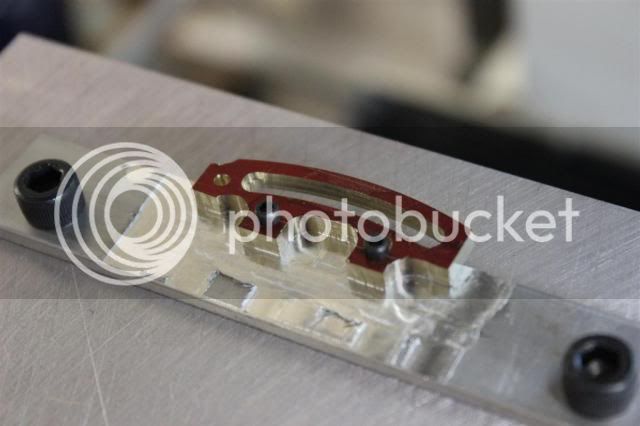

Then lastly, here they are all done.

Not sure what part I will make next, but I will be running out of things to make pretty soon!

Gary