- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

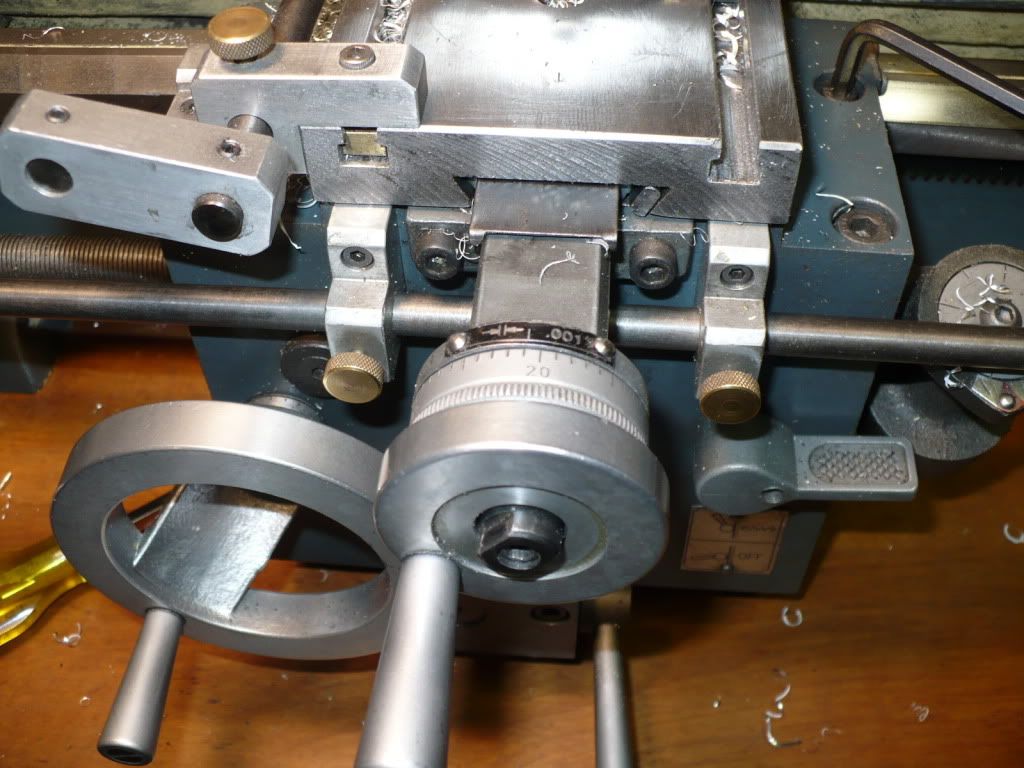

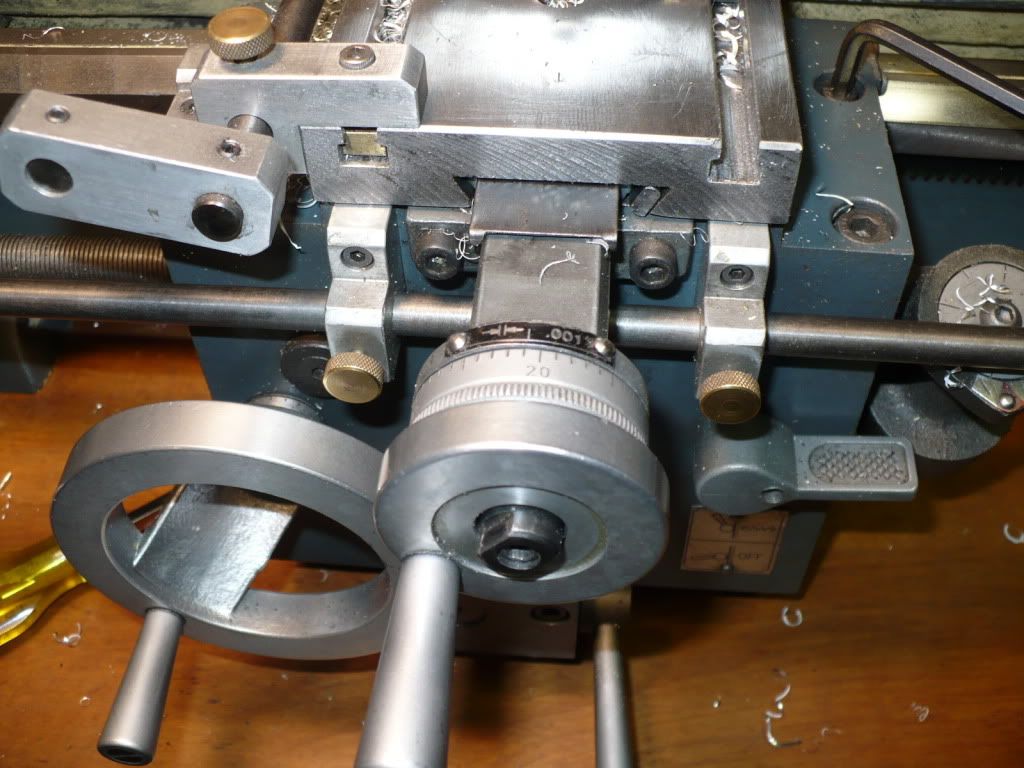

#1This was a rushed post so please excuse my messy machines. (picture guy was leaving the building). A dial indicator mounted on the gear box Is pushed by an adjustable carriage mounted 'travel rod'.

#2 Two brackets mounted on the carriage for the adjustable rod.

#3 An adjustable travel rod mounted to the top slide. And the dial indicator mounted to the carriage

#4 On the mill the indicator is mounted on the treaded depth rod and travels with the quill along the Z axis. The adjustable rod is mounted on the mills head. Its swiveled out into position and adjusted to a usable height.

This is a very inexpensive and accurate system that I use. Its easy to make and install, and the dial indicators are easy to replace if they get damaged. You Don't need an expensive system to get accurate results. I don't even bother to look at the calibrated hand wheels. What are they for? :big:

-MB

#2 Two brackets mounted on the carriage for the adjustable rod.

#3 An adjustable travel rod mounted to the top slide. And the dial indicator mounted to the carriage

#4 On the mill the indicator is mounted on the treaded depth rod and travels with the quill along the Z axis. The adjustable rod is mounted on the mills head. Its swiveled out into position and adjusted to a usable height.

This is a very inexpensive and accurate system that I use. Its easy to make and install, and the dial indicators are easy to replace if they get damaged. You Don't need an expensive system to get accurate results. I don't even bother to look at the calibrated hand wheels. What are they for? :big:

-MB