trlvn

Well-Known Member

Hi:

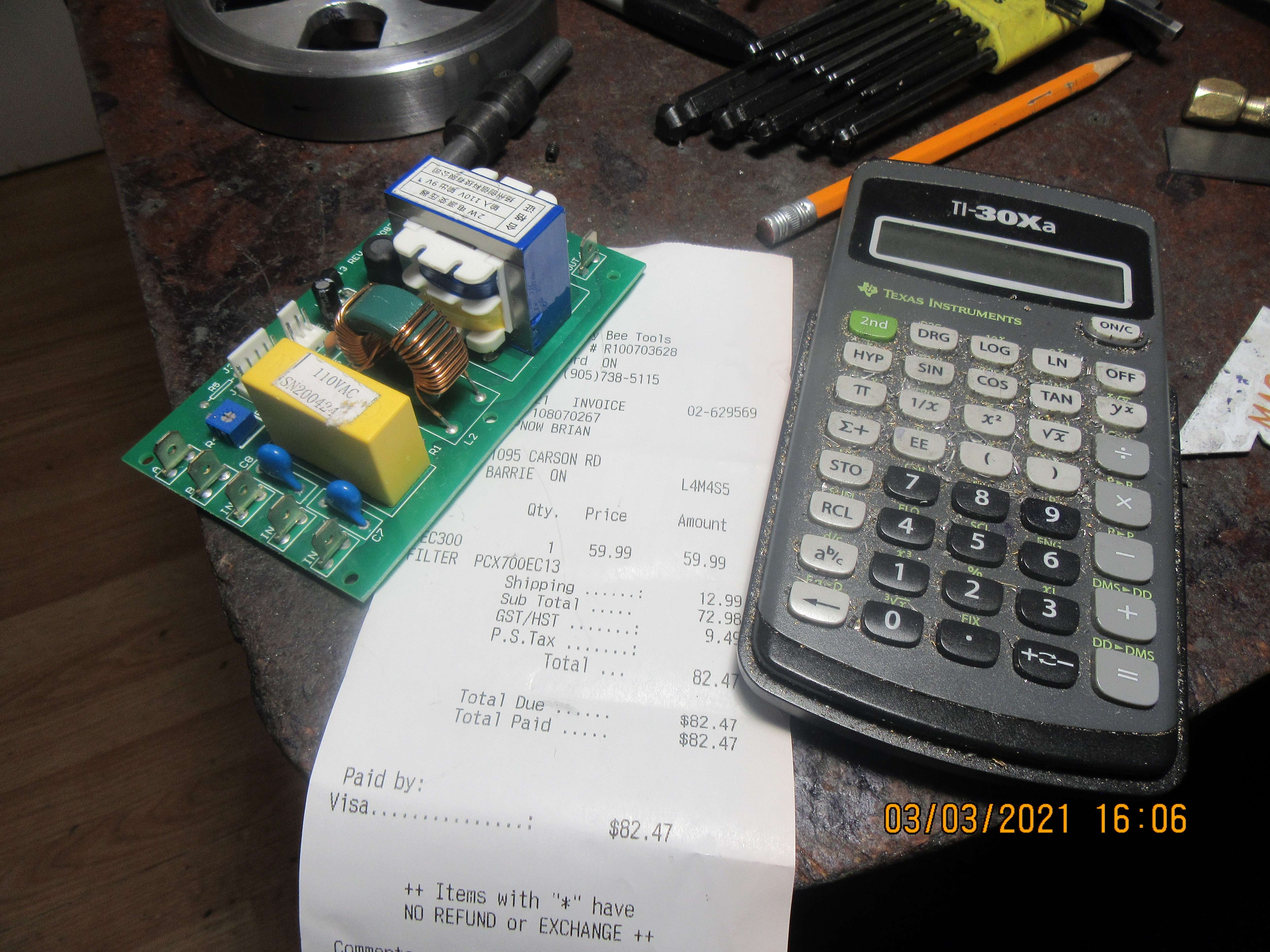

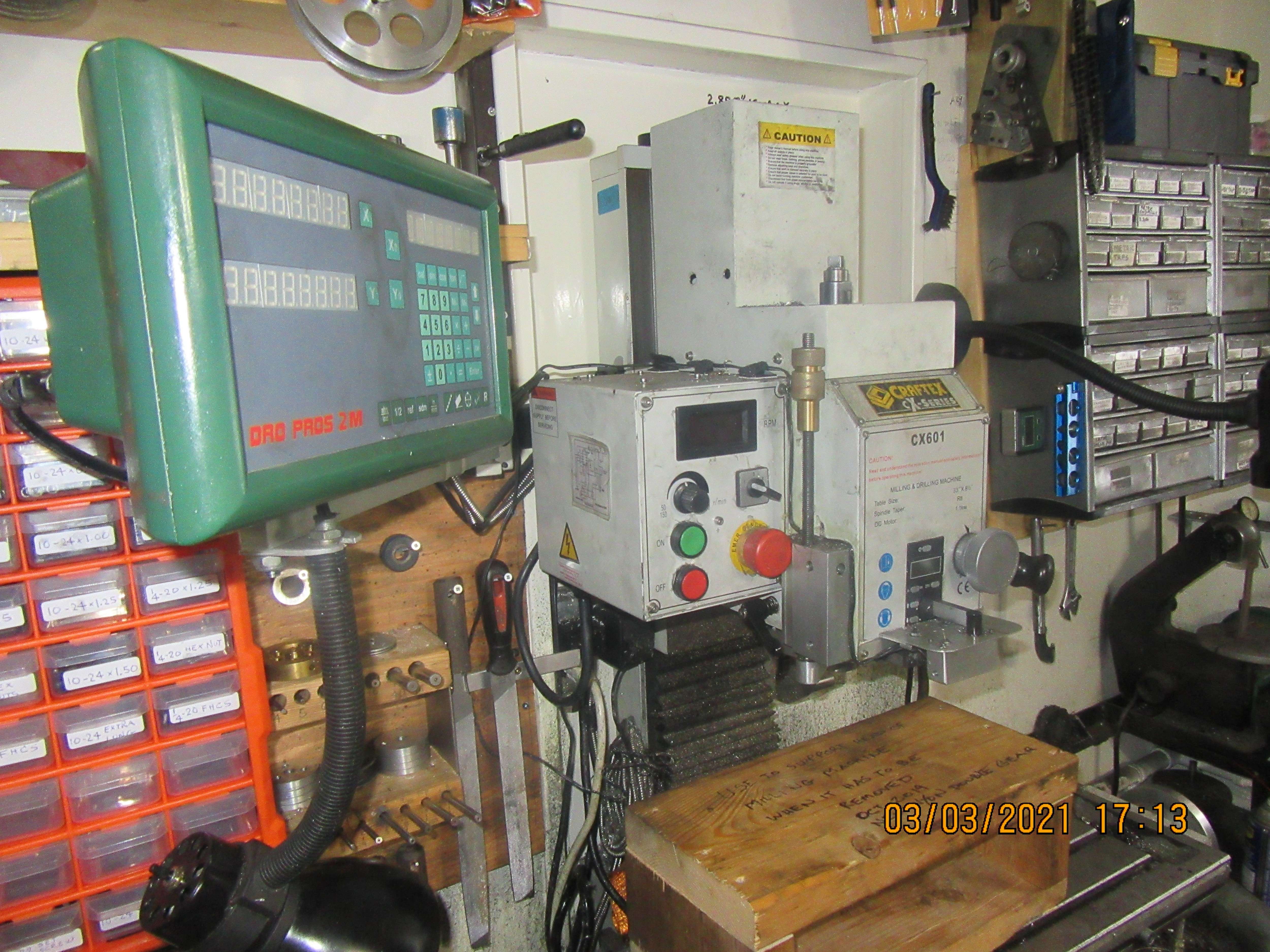

Just in case, the manual for your CX601 is available as a pdf from BusyBee:

https://www.busybeetools.com/pages/Manuals.html

[Search for CX6 and you'll get to the right spot.]

I didn't check but hopefully a parts diagram and list is included.

Craig

Just in case, the manual for your CX601 is available as a pdf from BusyBee:

https://www.busybeetools.com/pages/Manuals.html

[Search for CX6 and you'll get to the right spot.]

I didn't check but hopefully a parts diagram and list is included.

Craig