Rivergypsy

Well-Known Member

- Joined

- Oct 15, 2010

- Messages

- 432

- Reaction score

- 222

Well, you know what they say about kids with new toys? ;D

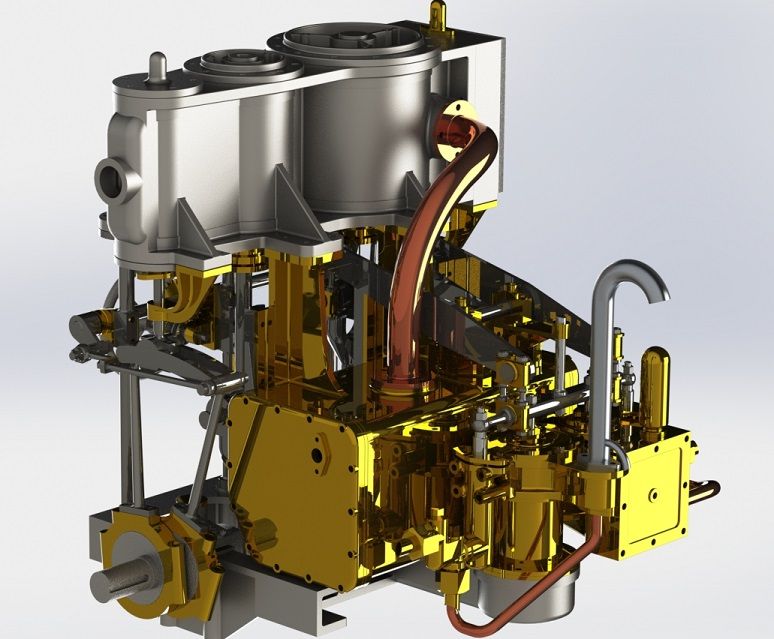

After postie delived a brilliant surprise this morning, I just couldnt help myself at lunchtime and took the bedplate down to the mill to start the cleanup. My initial thought was that I wanted the pads on the top face to be of equal height, so I used the main upper face as a datum, with a pair of parallels and a couple of clamps, and skimmed the lower rails. I used whats possibly an unusual cutter for iron, a Kennametal high rake twin tipped 20mm facemill, and the iron cut like butter absolutely beautiful. If the rest of the castings are even close to this one then were in for a stunner here!Thm:

Once those rails were clean I flipped it over on to a larger set of parallels, and it sat flawlessly level. Securing it again with a pair of clamps, I then cleaned the top face. It took around 1mm to clean up, but that was down to one of the bearing cap faces (at A) just being slightly low, but its no problem at all as theres bags of material left.

I didnt bother at all about any other faces being true, but at least now there are two datum faces to use for working out where we go from here. Its been a fair while since Ive machined any iron, but this was a pleasure, and with absolutely zero porosity or inclusions

Oh, and I did take a load of setup pics on my Ipod, so Ill get those off tonight and post them ;o)

Overall, it has to be said that it's really great to get started on this, and proportion wise it promises to be a stunner!

woohoo1woohoo1woohoo1

After postie delived a brilliant surprise this morning, I just couldnt help myself at lunchtime and took the bedplate down to the mill to start the cleanup. My initial thought was that I wanted the pads on the top face to be of equal height, so I used the main upper face as a datum, with a pair of parallels and a couple of clamps, and skimmed the lower rails. I used whats possibly an unusual cutter for iron, a Kennametal high rake twin tipped 20mm facemill, and the iron cut like butter absolutely beautiful. If the rest of the castings are even close to this one then were in for a stunner here!Thm:

Once those rails were clean I flipped it over on to a larger set of parallels, and it sat flawlessly level. Securing it again with a pair of clamps, I then cleaned the top face. It took around 1mm to clean up, but that was down to one of the bearing cap faces (at A) just being slightly low, but its no problem at all as theres bags of material left.

I didnt bother at all about any other faces being true, but at least now there are two datum faces to use for working out where we go from here. Its been a fair while since Ive machined any iron, but this was a pleasure, and with absolutely zero porosity or inclusions

Oh, and I did take a load of setup pics on my Ipod, so Ill get those off tonight and post them ;o)

Overall, it has to be said that it's really great to get started on this, and proportion wise it promises to be a stunner!

woohoo1woohoo1woohoo1