Any large agricultural tyre supplier should have them, these people have tyres from 6" to 55" rim diameters

https://www.farmtyres.co.uk/tractor

https://www.farmtyres.co.uk/tractor

Very impressive - - - - - I wonder where the tires for those models were obtained from - - - - anyone with ideas?

Very impressive - - - - - I wonder where the tires for those models were obtained from - - - - anyone with ideas?

this thread started out as an important issue, how to keep casting kits alive after the original maker passes away, but has been hijacked into how hard casting is (don't care, those who want to cast will figure it out, its been done before, it will get done again), and who wants what size of engine (don't care, those who really want larger or smaller engines can do their own rescaling), not strictly relevant

digital media are certainly not stable, floppy disks are essentially unreadable now and the same will eventually be true of CDs, but the internet itself (ie cloud storage) is technology agnostic and our entire society is built around it being continually maintained, so is reliable (until the collapse of western civilization, after which model engine building won't be very easy anyway), an example of how good cloud storage is is that google-books has stuff from the 1800's that you can't in general see any other way (this is how I got plans for the Muncaster #9 Joys Valve steam engine, and also drawings for the original full size Van Vleck Triple Expansion steam engine but without the dynamos)

I'd like to see a museum where original patterns are kept, and digitized, and the data freely available for download, then folks can 3-D print new patterns and make their own castings and/or send them away to a foundry. the museum could also hold old magazines, for example back issues of StrictlyIC are no longer available until the current copyright owner decides what to do with them, but this is what I think should happen to them.

an example of the sort of issues involved is that for example this website has a files section that can (does!) hold this kind of data, but this website is at the mercy of its owner who might someday decide its not worth his time/effort/trouble to maintain, what then ? a similar concern can be raised regarding Joe Martin's Craftsmanship Museum. and I hear rumors that Stuart Models Inc has changed hands a couple times recently, what if they go out (how to avoid what I see as the ensuing catastrophe of their castings no longer being available (sorry PMResearch, your casting are good but your styling isn't, IMHO !)). so I guess the question is how can something be set up so that it will be run in perpetuity

thoughts ?

comments ?

questions ?

I've published some of my designs both freely available or in magazines so others can recreate these engines buy the same methods I use so at least I am helping keep some alive as well as keeping other casting sets available by helping out with pattern making.

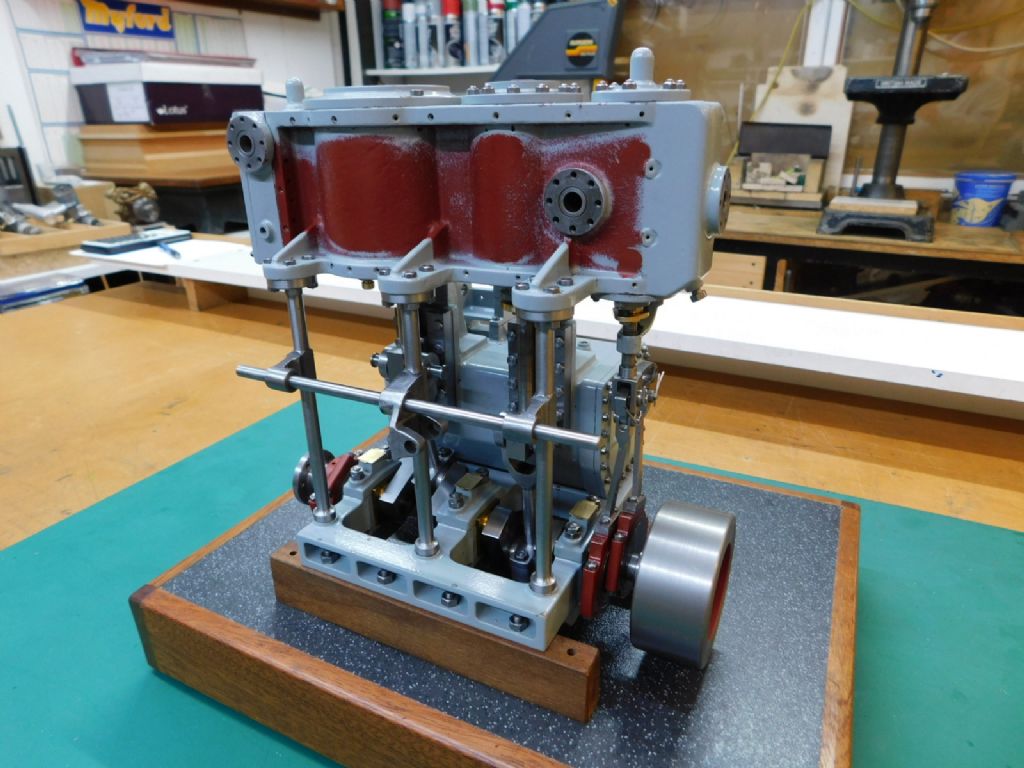

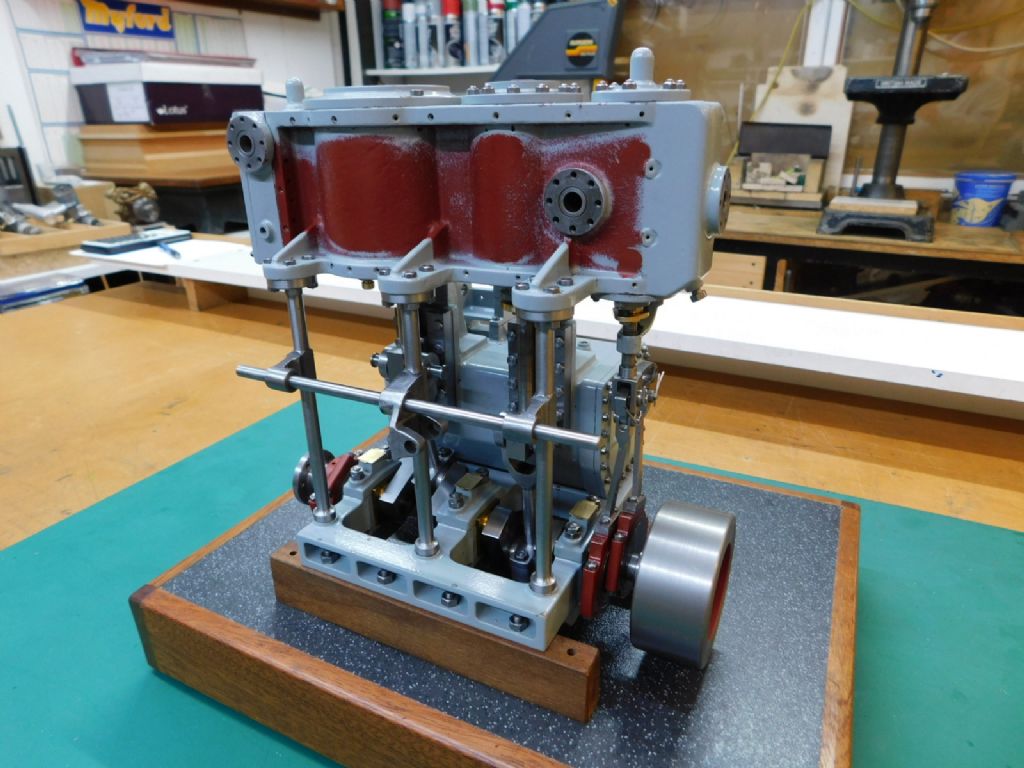

I have a set of castings and drawings of this engine for sale...check the other forum!When casting kits of that marine engine were last on sale by Historic Models and Reproductionsthe the cost to them was $2100 and now likely to be well over $2500 for the ductile iron and E85 castings so a very limited market as only 3 of the initial run of 5 sold. They also had the cost of the preproduction prooving castings to swallow as well as developement time over several years. Retail would now be in the region of $5000 based on markups I know are used. Patterns are held by a foundry at the moment.

Same engine being built with all the main castings made from iron but not cast, no doubt at a considerable cost saving.

Keeping the art alive is OK if it is affordable and if you do have the cash can find somewhere to do the casting.

Even if you do find a foundry willing to cast you may have to try a few to get the quality you require or ones that are able to pour what you want made. For example a recent pattern had to be altered as the foundry felt they would not be able to pour the thin sections yet other foundries are quite able to cast a lot thinner. Though the patterns are best made of metal as wood and even 3D printed (particularly if not solid fill) ones may get damaged by a foundry using airset and not taking as much care as someone ramming up by hand, another cost to be considered when offering kits again

Pat why don't you just get a new e-mail address like a free gmail one and register as a new member.

you would still be able to see me making cast iron flywheels without melting any metal.

Enter your email address to join: