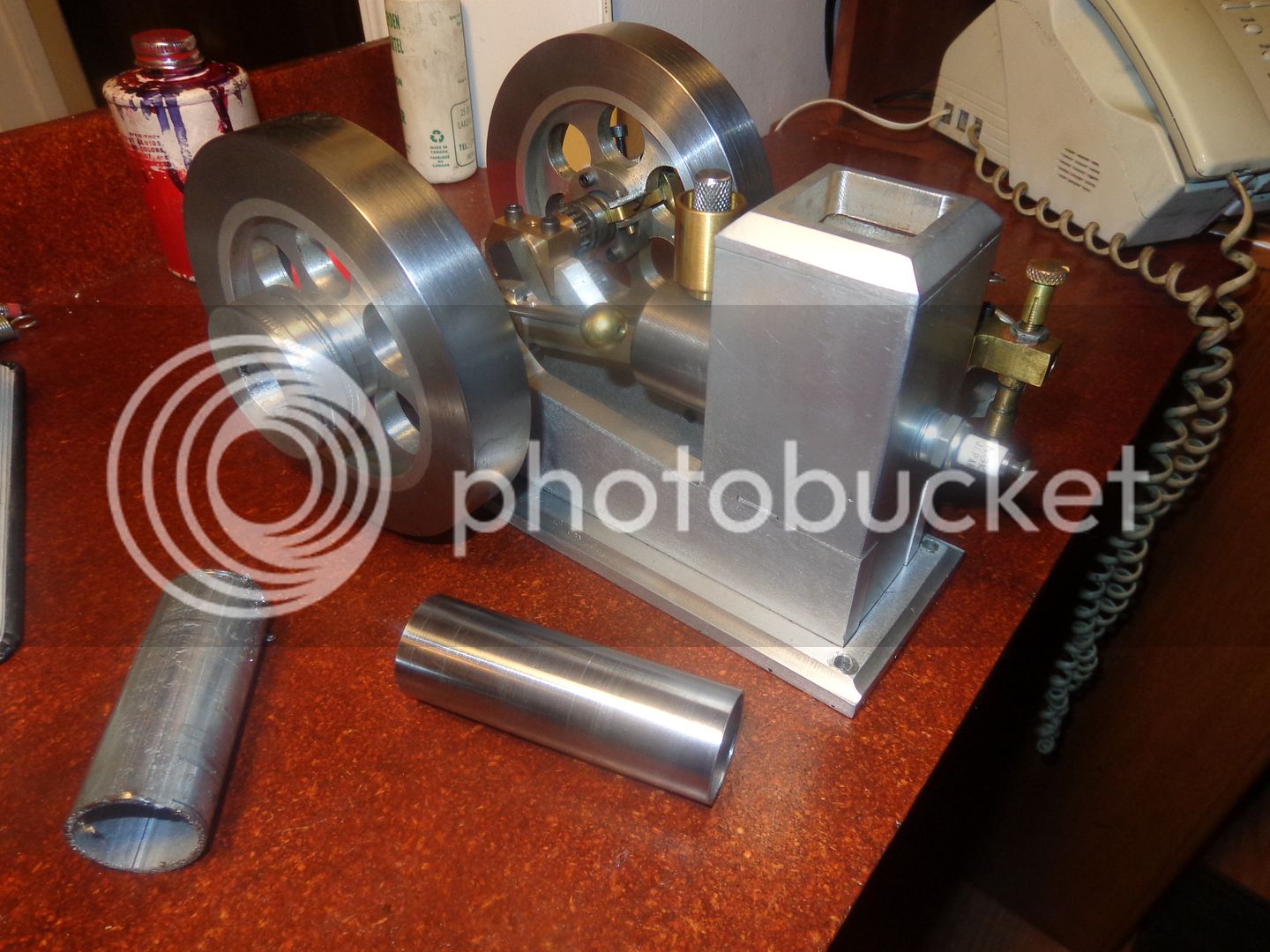

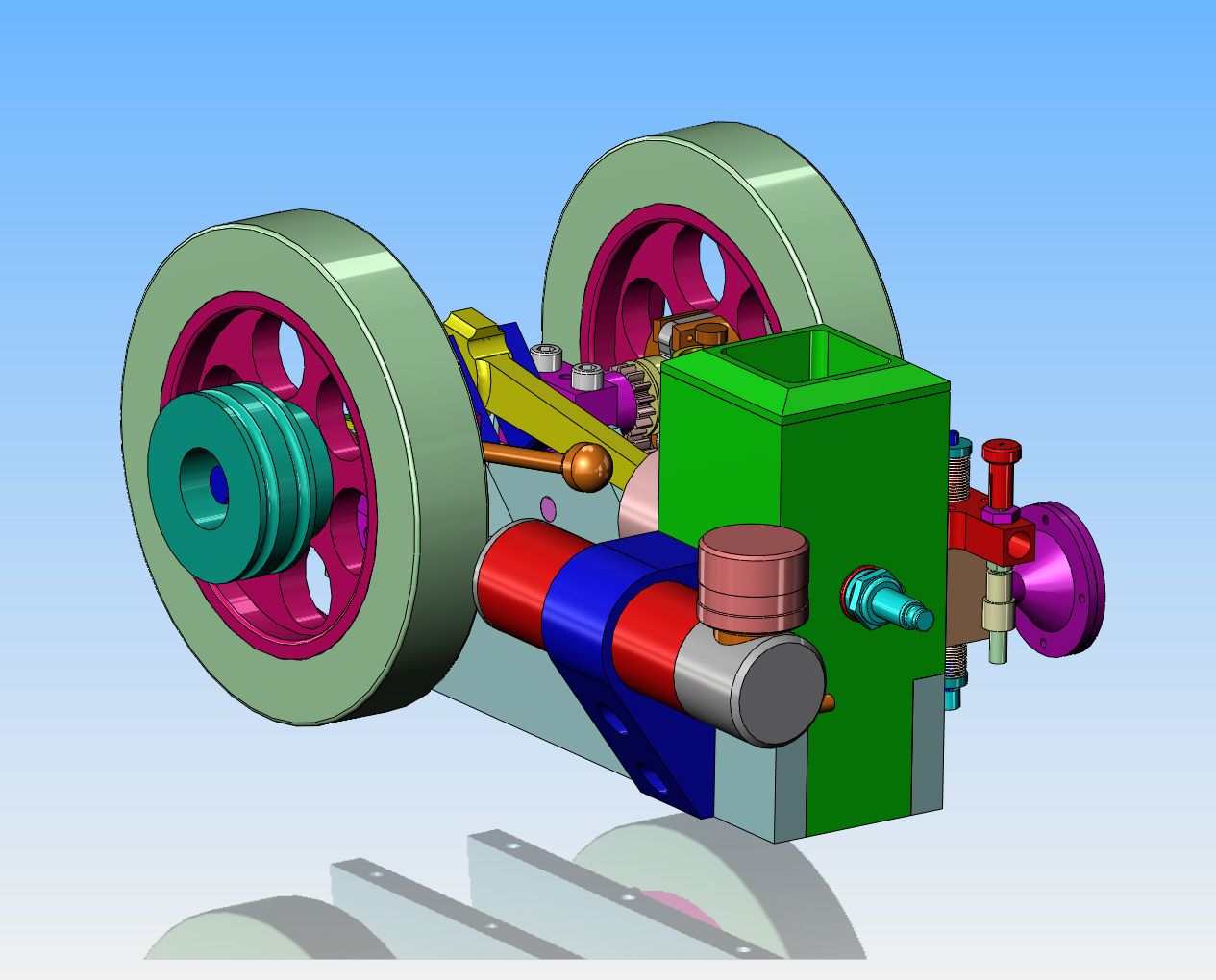

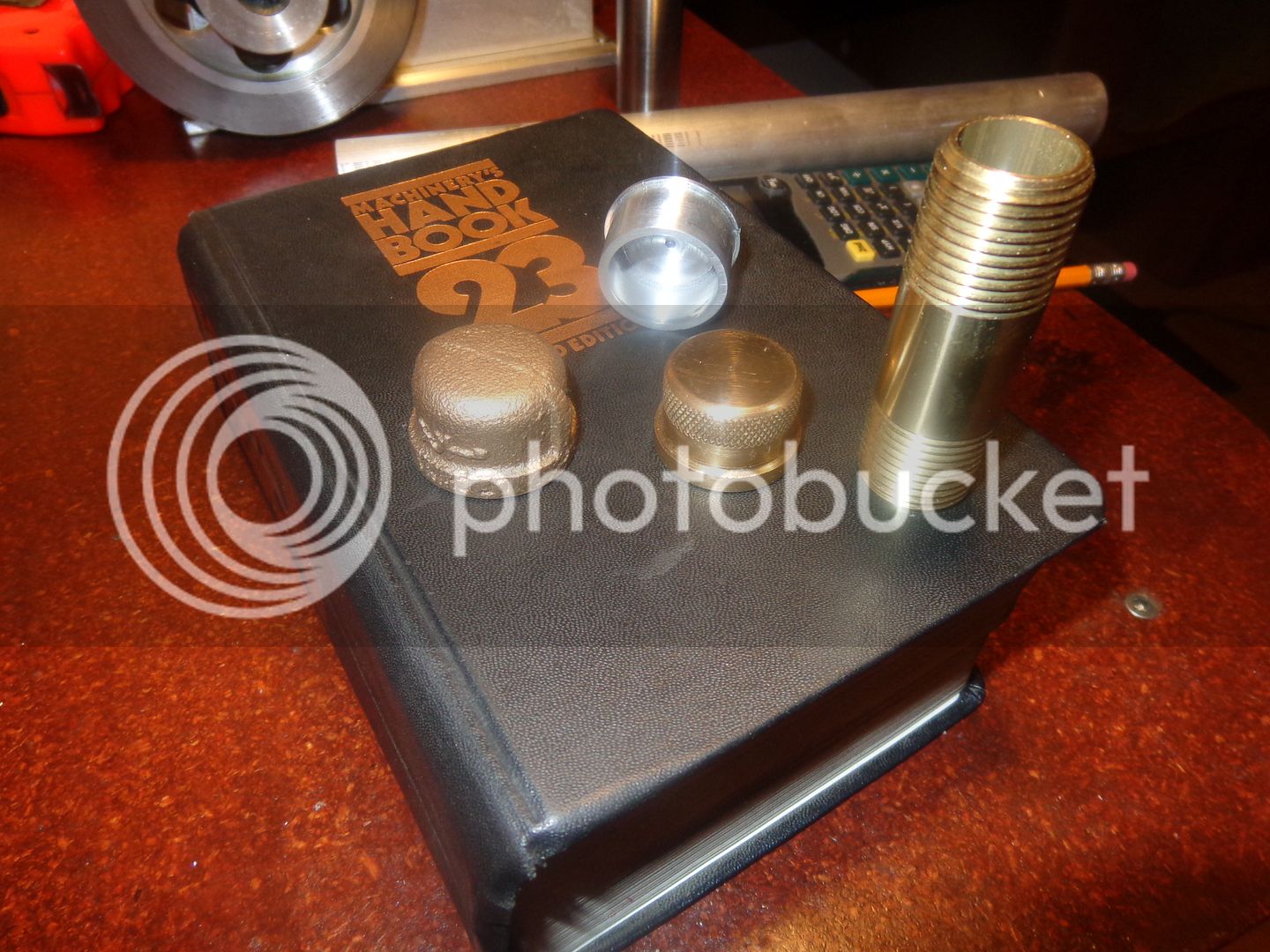

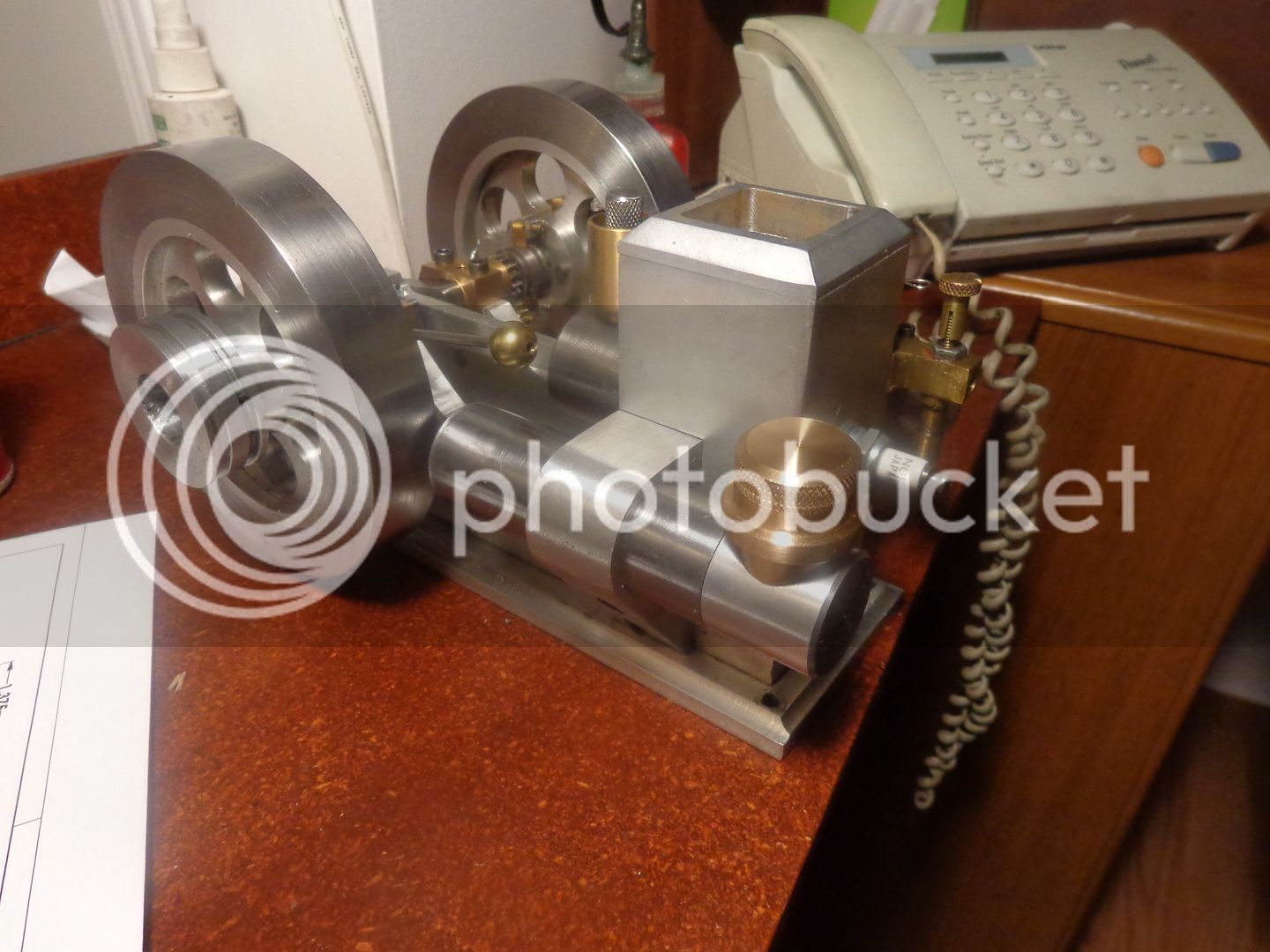

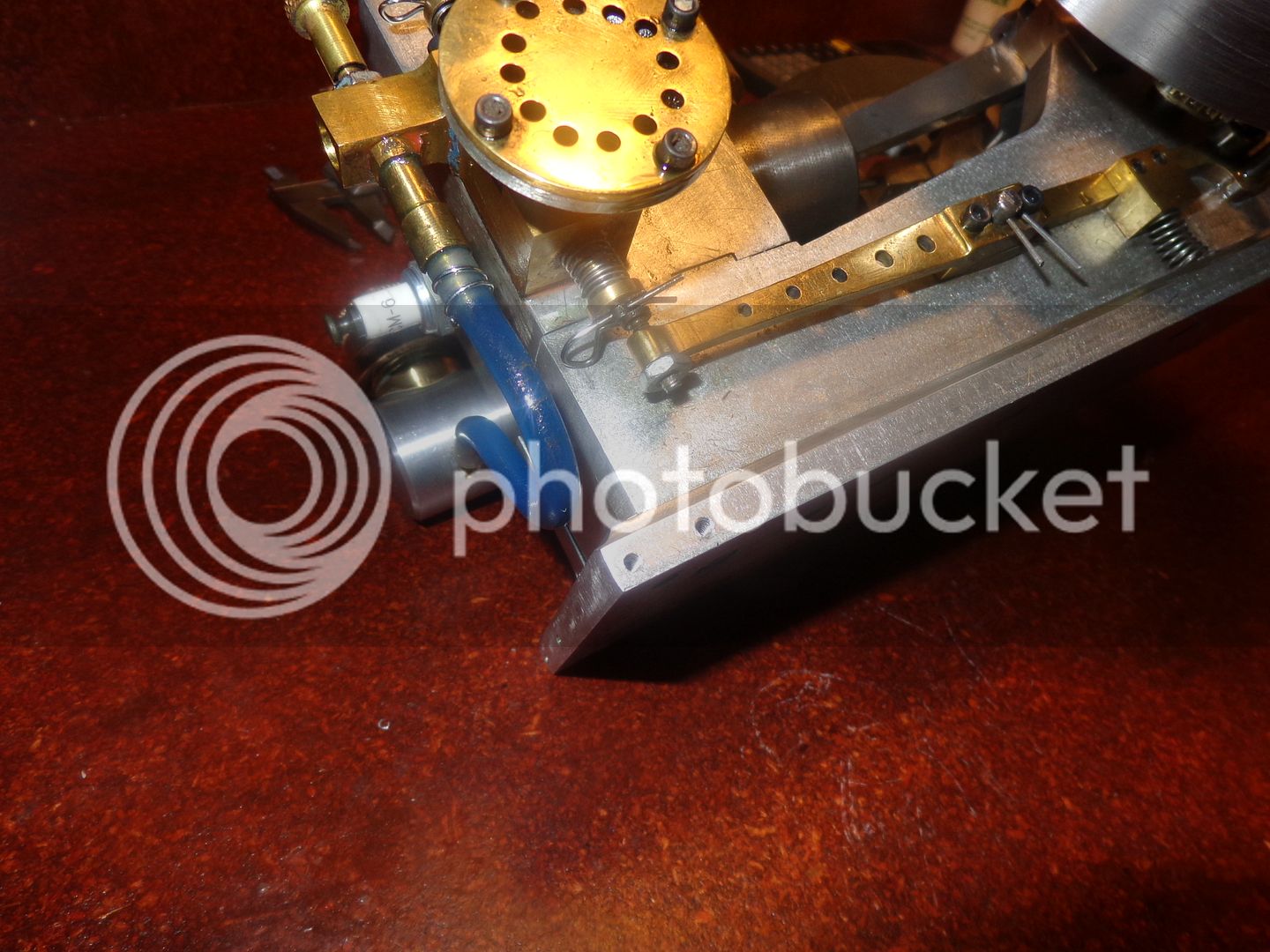

When I built my Philip Duclos "Odds and Ends" engine a couple of years ago, I never did build a satisfactory gas tank. I have some "down time" now, so thought perhaps I should build a gas tank for it. Since I don't have a separate base that the engine mounts on, I have decided that the gas tank must mount on the engine itself. A hunt through my "bits and pieces" bin yielded a length of galvanized steel tubing 1.165" outer diameter x 1/16" wall thickness. I didn't want to have to deal with the galvanized finish, so I set it up in my lathe and turned the outer diameter to 1.144" diameter, which (I hope) got rid of the galvanizing on the o.d. of the pipe. The piece I turned is 3.48" long. This was a somewhat arbitrary length, but all that matters at the moment is that it be 'long enough". In the picture you can see the unturned length and the turned length setting in front of the engine.