Brian,

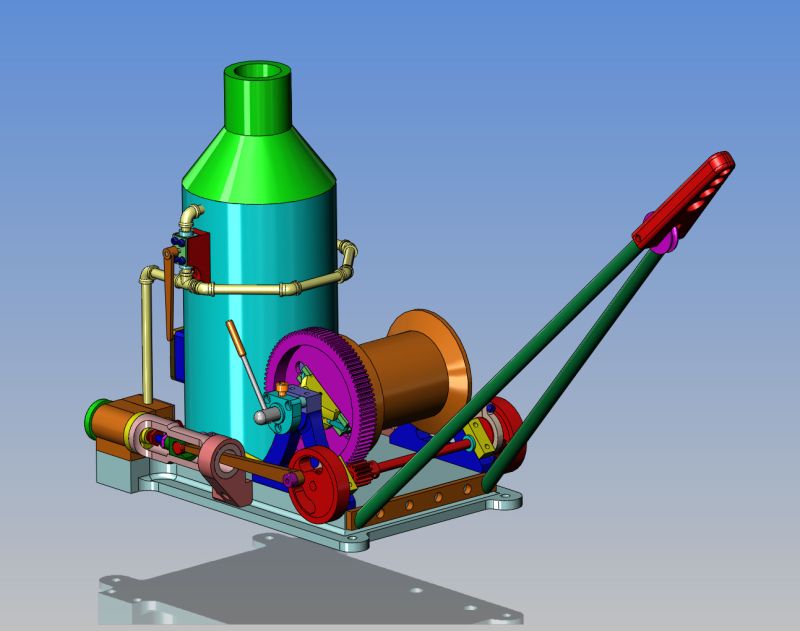

Yours and Jerry's donkey projects are addictive reading. Were I to be able to build one of these (Maybe someday...), I know I would spend a lot of time running it and lifting things and all that.

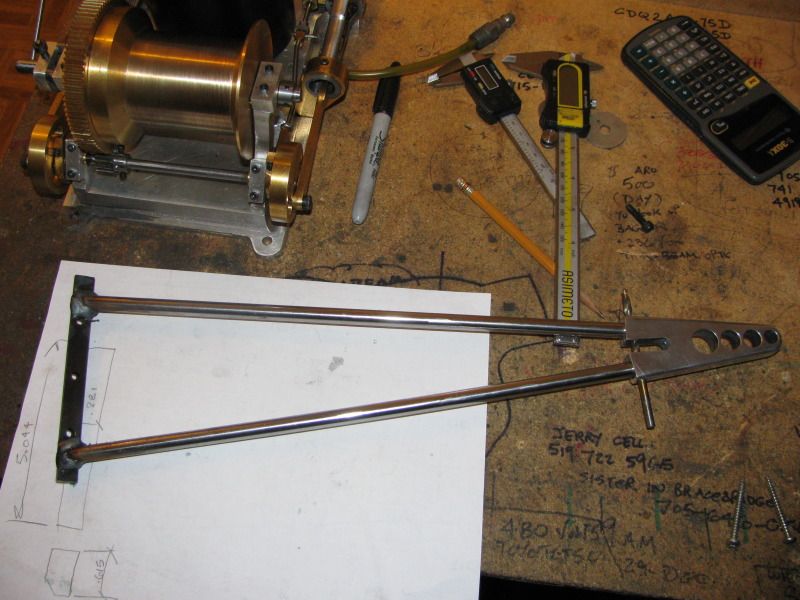

I have never seen one of the full-size hoists in operation, but I have seen winches that are similar being used to assist pulling ropes to move things around. (with a team of men pulling on the ropes.) Perhaps you could make some small snatch blocks as accessories.

I don't mean to add work, I just saw it in my mind's eye and couldn't resist posting.

Congratulations again.

--ShopShoe