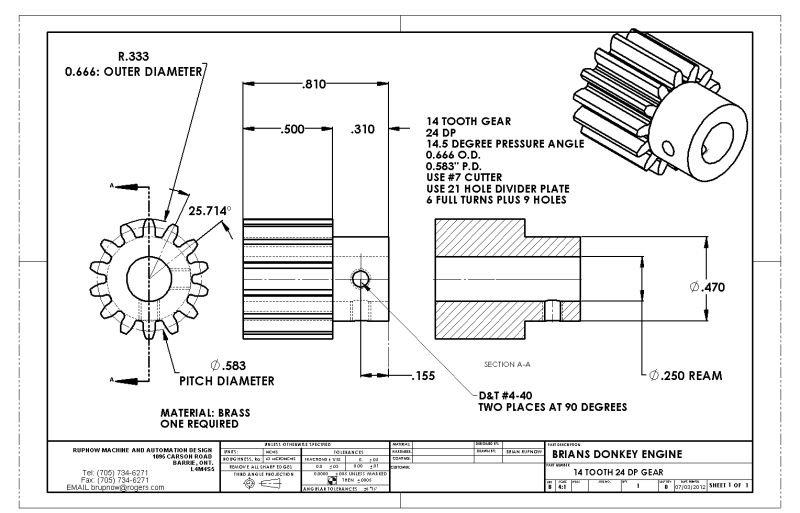

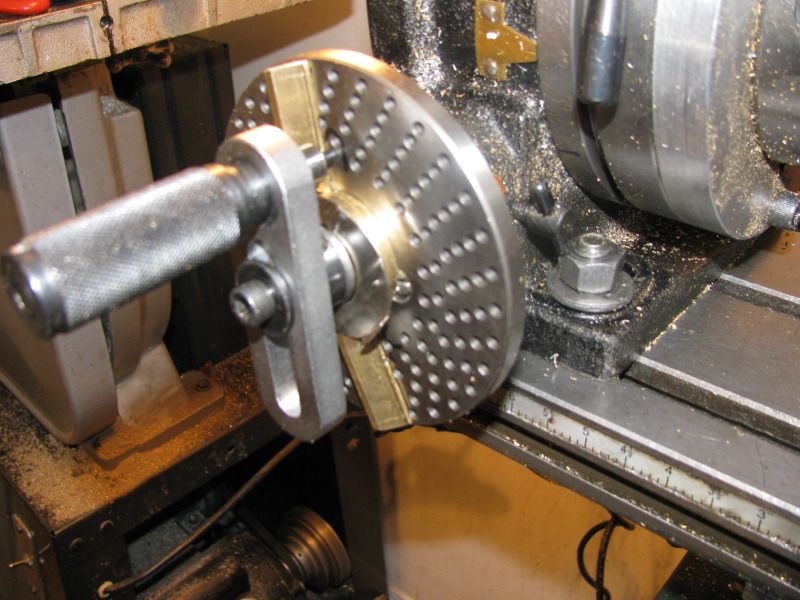

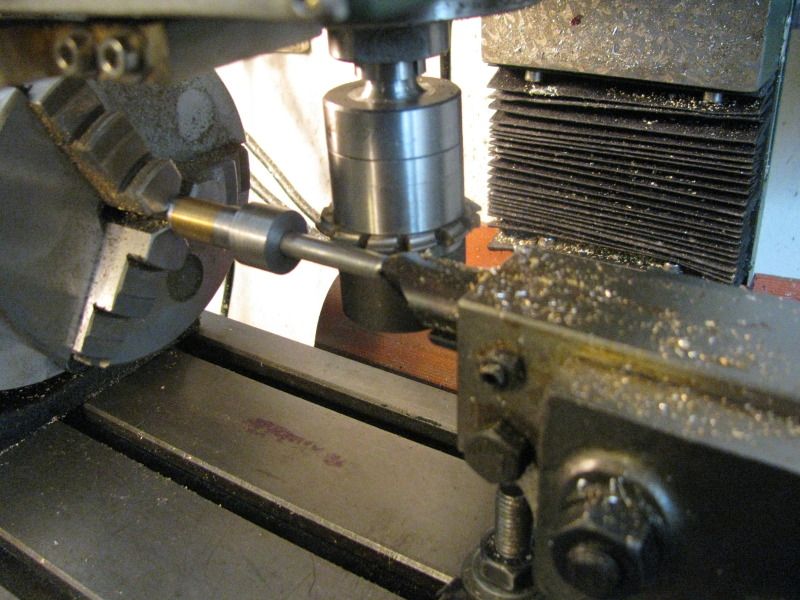

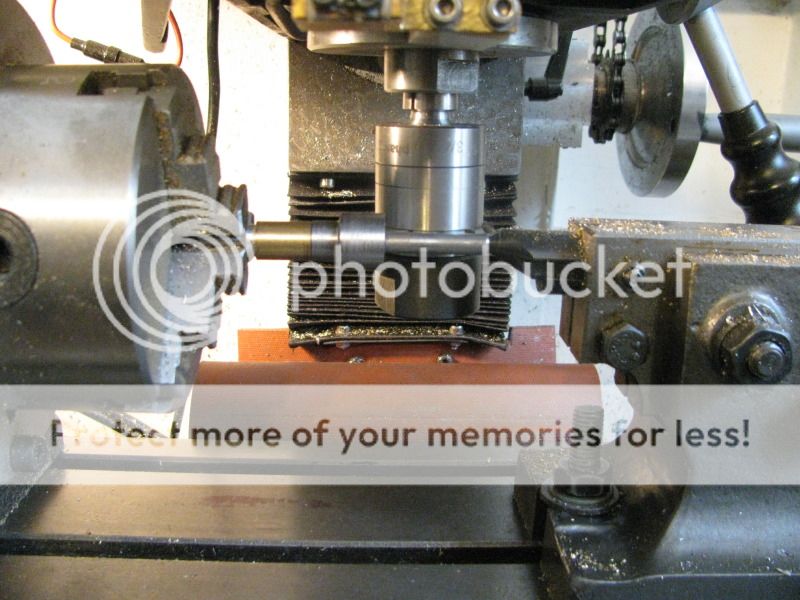

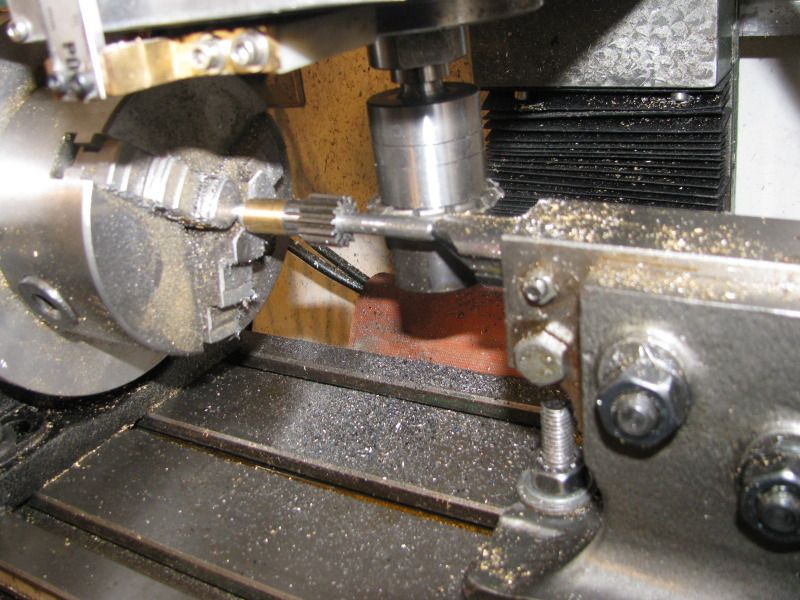

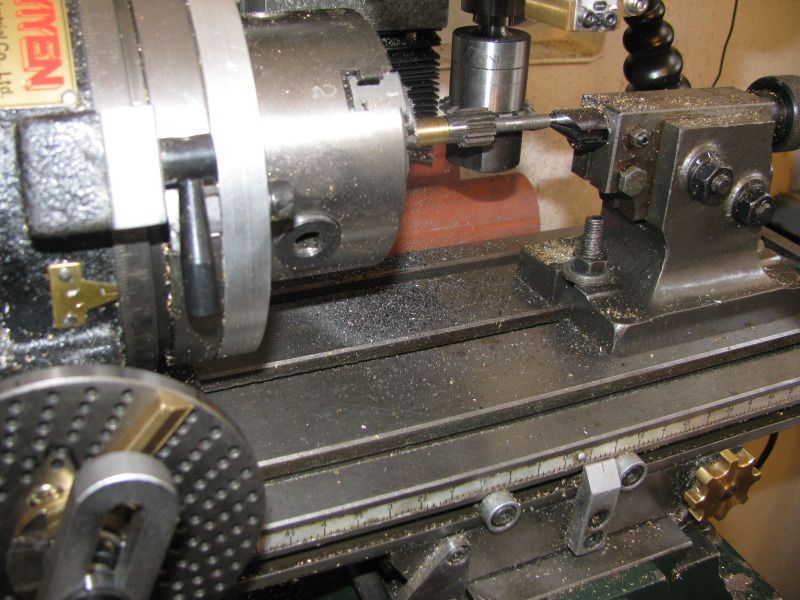

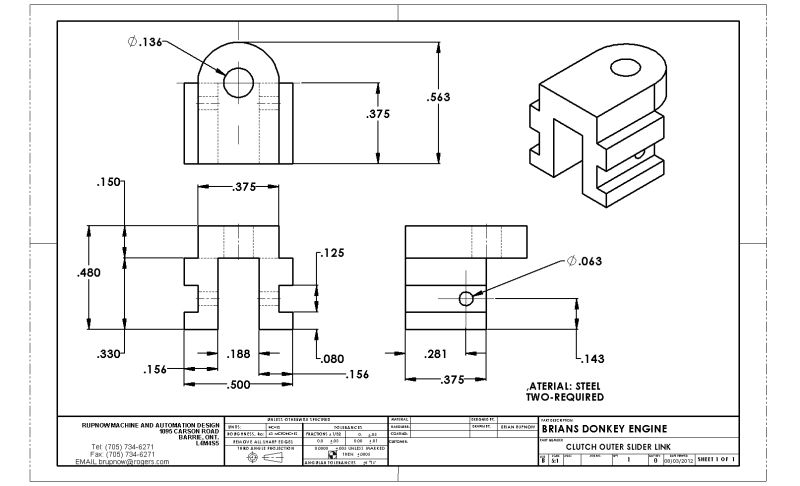

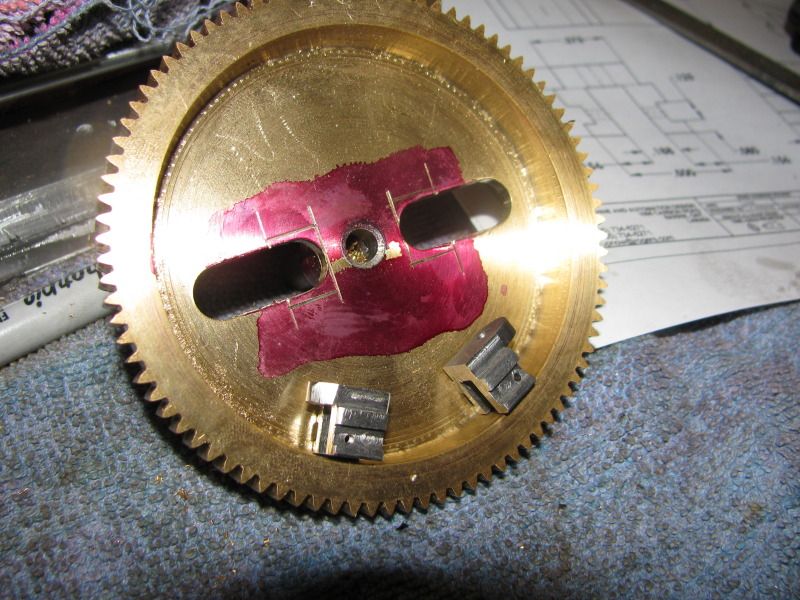

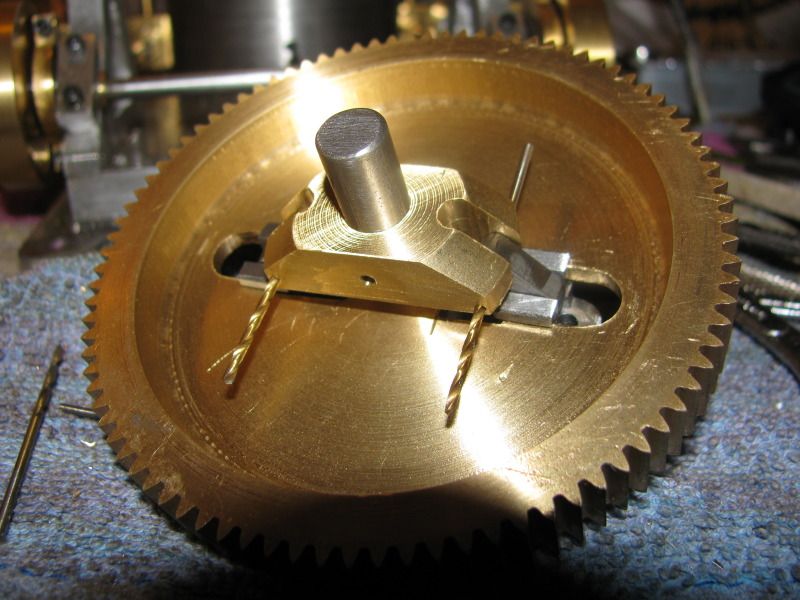

Sticking with my theme of "Tell the truth even when it shows you're a dummy"----I went ahead and made the 12 tooth gear this afternoon. When I went to make it, I see that my charts call for a number 8 cutter. Damn---Thats weird!!! I haven't got a number 8 cutter. My cutters only go up to number 7.---Oh well, we'll use the number 7 cutter anyways---it will probably be close enough. Made the blank and machined the gear. Now, lets do a little math and calculate the center distance between the gears and we'll make a mounting block to see how they mesh.---Lets just check the solid model and make sure that the centers I calculated 5 weeks ago are the same. WHOA NELLY--They're not the same!!! Well, I'm not about to go back and change the bearing stands, so we'll use the center distance off the solid model. As you see in the picture---don't mesh worth poop!!! Okay----I'm not that dumb!!! Time to play detective!!! I know the pitch dia. of the large gear. If I take half that away from the center distance on my bearing stands, and multiply the answer by2 that will give me the pitch diameter of the pinion.---well, son of a gun!---Works out perfect for a 14 tooth gear!---And I have the proper cutter and 21 hole plate to make a 14 tooth gear. SOMEWHERE along the way, I got distracted and modelled a 12 tooth gear, but my overall design was based on a 14 tooth gear. No harm--No foul. Now I know why this is called a Donkey engine. I'm a donkey. Tomorrow I'll make a 14 tooth gear.----Brian