Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

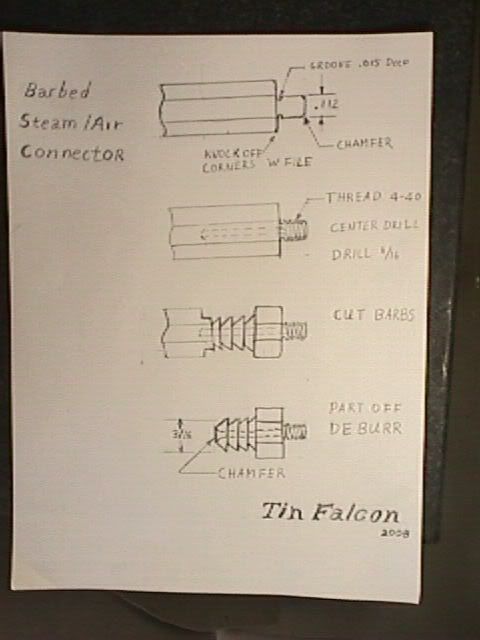

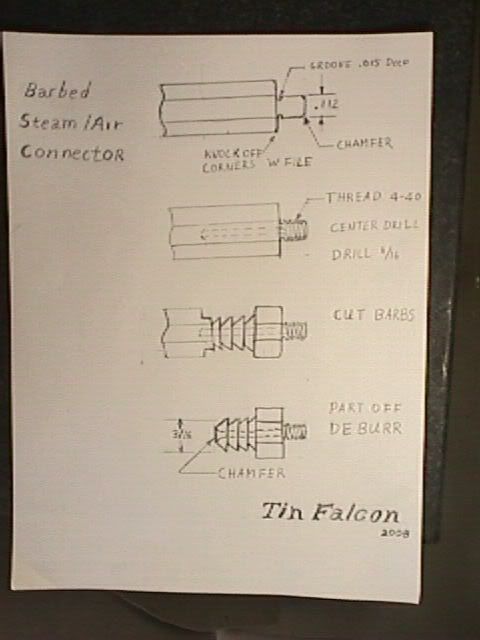

As many of you know I posted a photo of a steam fitting that I use on my engines.

Bob has expressed an interest in using that design for the team build.

I promised him some suggestion of how to machine it. Not that it is a hard part but there are a couple of pitfalls to avoid . for instance if you drill the hole then thread with a die it is not hard to rip the newly threaded section off the end of the part.

Bob: rather than sending the info in a PM or e-mail decided to post it here for all to benefit from. Use this as a guide. hope it helps. then add to this thread with photos etc. so here is a sketch I did up. If you have questions just ask glad to help.

Be sure to de-bur /smooth all edges preferably in the lathe.

Tin

Bob has expressed an interest in using that design for the team build.

I promised him some suggestion of how to machine it. Not that it is a hard part but there are a couple of pitfalls to avoid . for instance if you drill the hole then thread with a die it is not hard to rip the newly threaded section off the end of the part.

Bob: rather than sending the info in a PM or e-mail decided to post it here for all to benefit from. Use this as a guide. hope it helps. then add to this thread with photos etc. so here is a sketch I did up. If you have questions just ask glad to help.

Be sure to de-bur /smooth all edges preferably in the lathe.

Tin