Gazzaleach

Active Member

- Joined

- Jan 11, 2013

- Messages

- 31

- Reaction score

- 9

Hello Guys,

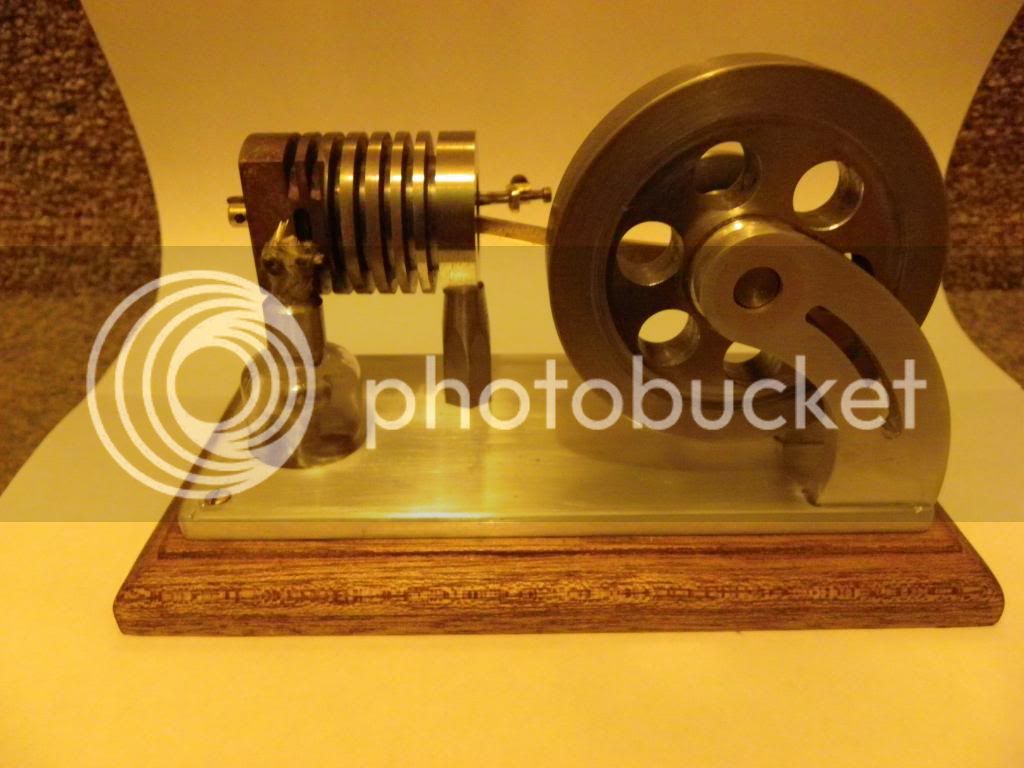

I started this build before i joined this forum and thought it looked simple to build with my limited knowledge i downloaded the plans from Jan Ridder!

Now today i did a little search on this forum and had several hits for this engine and various other`s and was horrified to read that this is no engine for the novice like myself. I have already machined all the large parts this includes the cylinder which from my reading has to be to a very close fit? I have attached some pictures of my cylinder i think my fit should be ok but any advice would be great.

Many thanks Gaz

I started this build before i joined this forum and thought it looked simple to build with my limited knowledge i downloaded the plans from Jan Ridder!

Now today i did a little search on this forum and had several hits for this engine and various other`s and was horrified to read that this is no engine for the novice like myself. I have already machined all the large parts this includes the cylinder which from my reading has to be to a very close fit? I have attached some pictures of my cylinder i think my fit should be ok but any advice would be great.

Many thanks Gaz