Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Progress Report,

SWMBO had no plans for me today, she and our credit card are recovering from another city trip. I almost managed a full day on the engine but stopped at a point where if I had continued I would still be in the shop. I'm sure you know what I mean.

On with the saga - I managed to make and fit the Crankcase end cover and make a start on the Cylinder.

Slide show follows

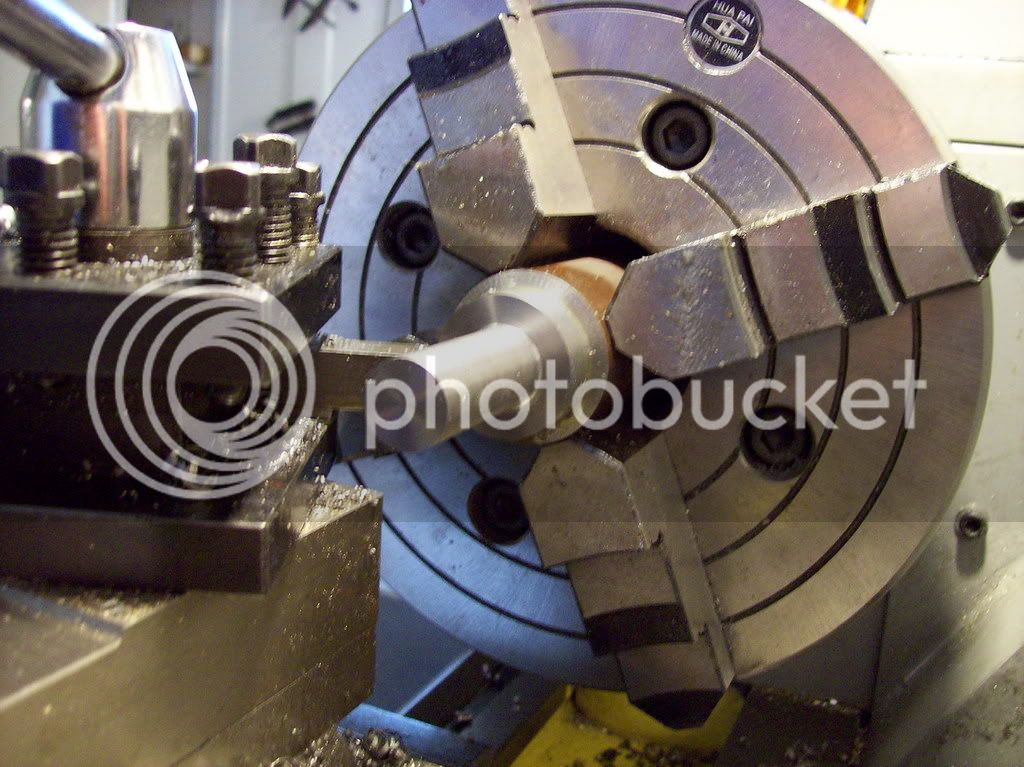

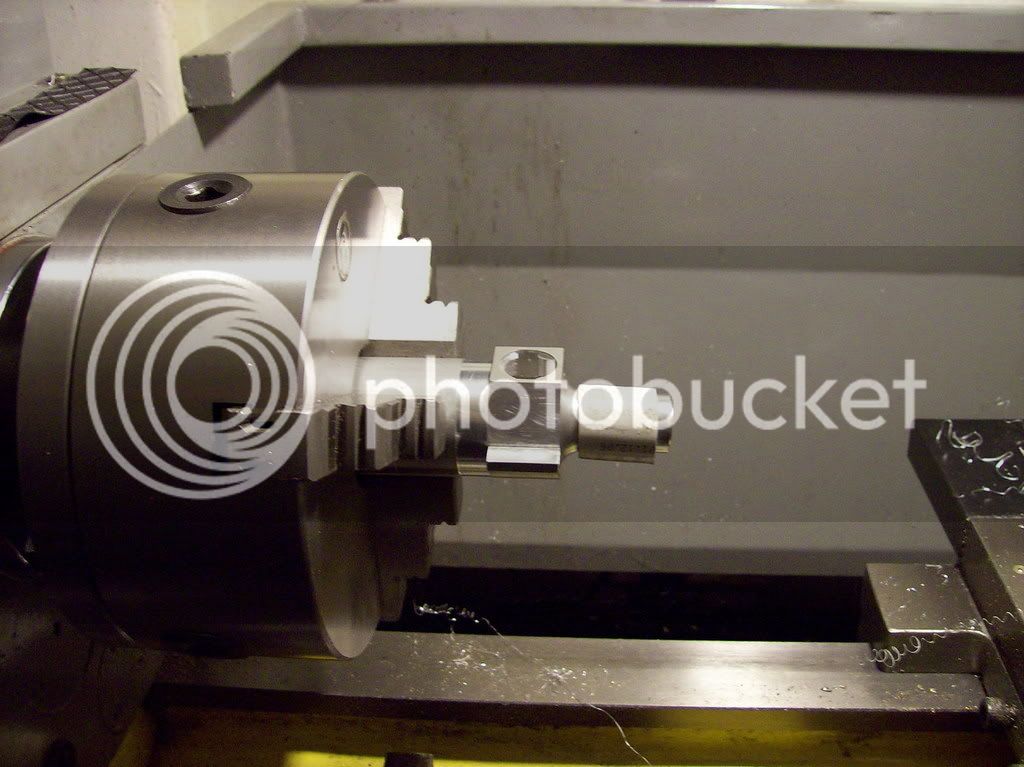

After the initial machining - checking the fit of the crankcase on the end cover.

Machining the outer face

The outer face counter bored

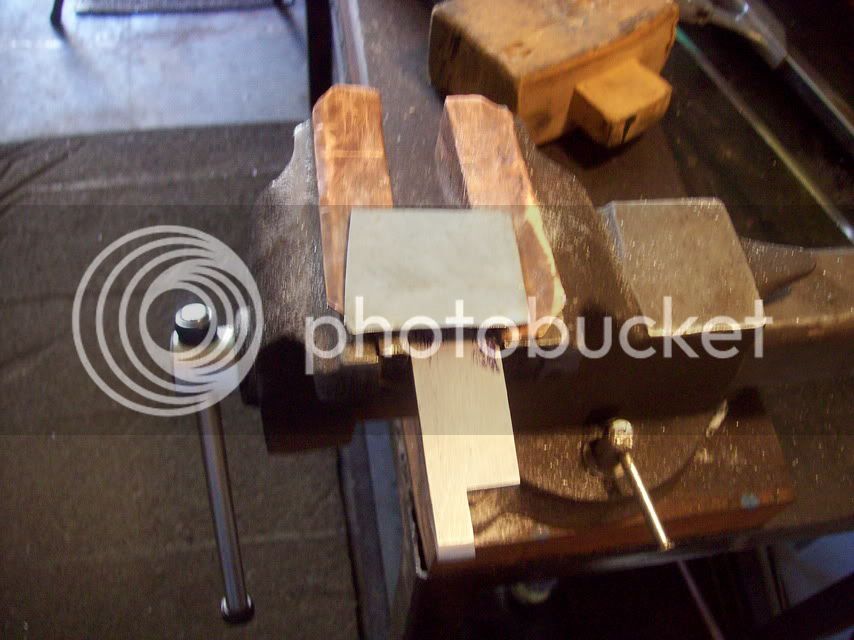

Marking out the end cover for the stud holes

Drilling the stud holes

Using the end cover as a template for the stud threads in the crankcase

Tapping the crankcase 6BA and Oh so easy to tear a thread out in Alu!!

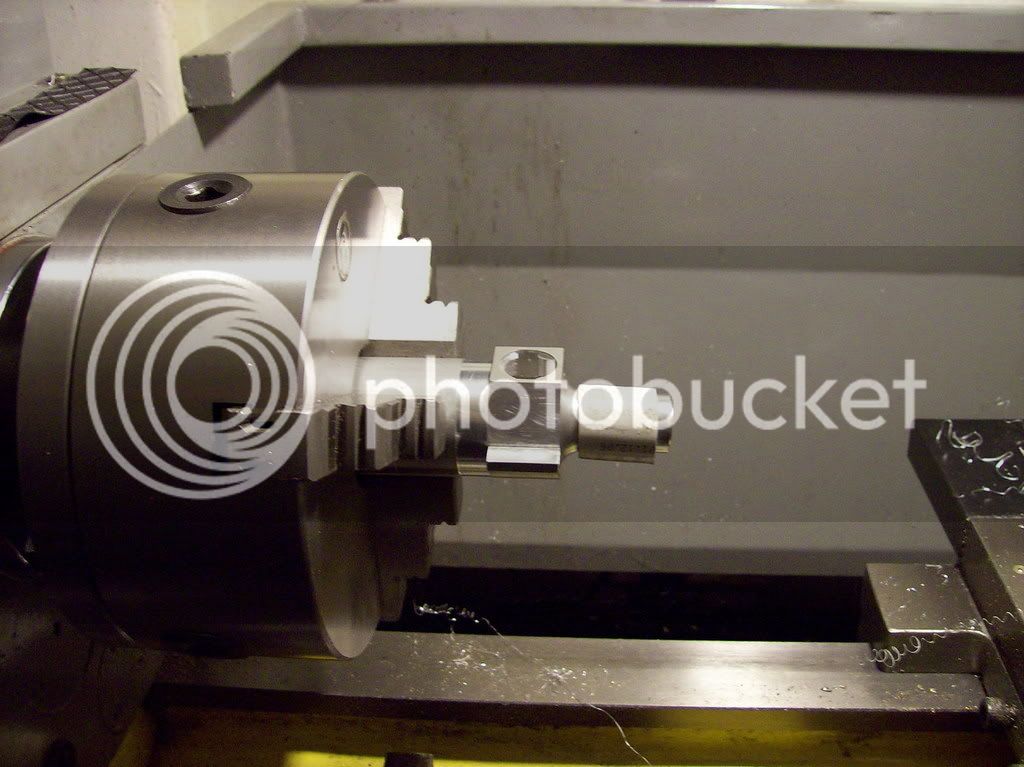

Phew the studs are fitted

The crankcase with the end cover in place.

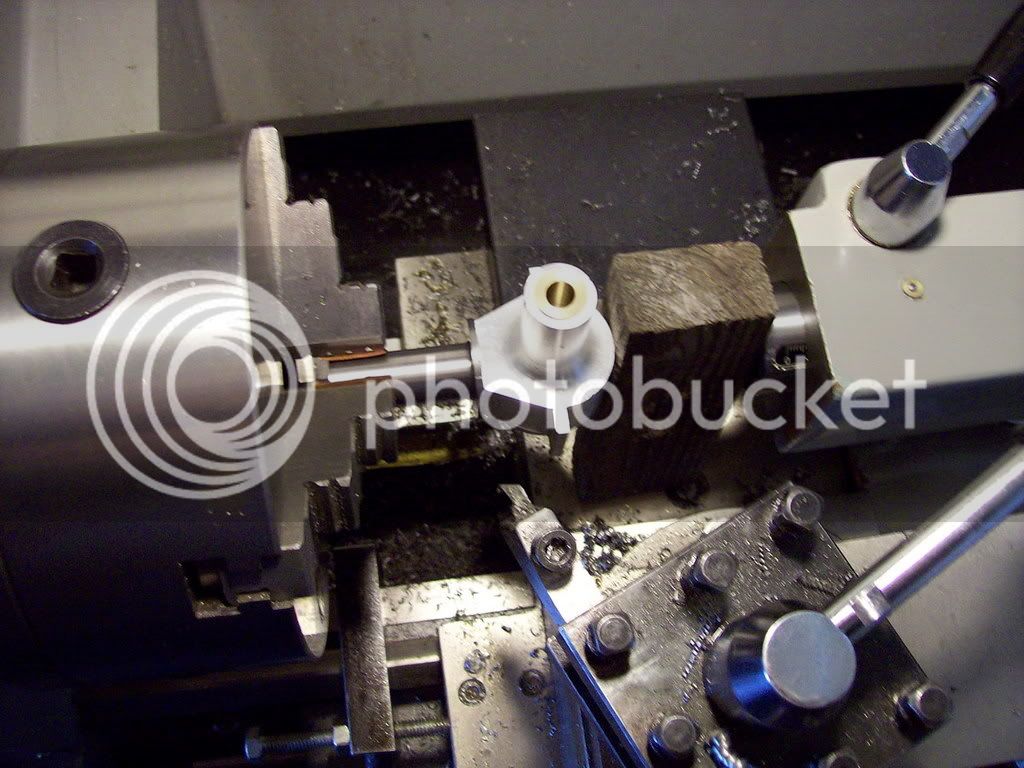

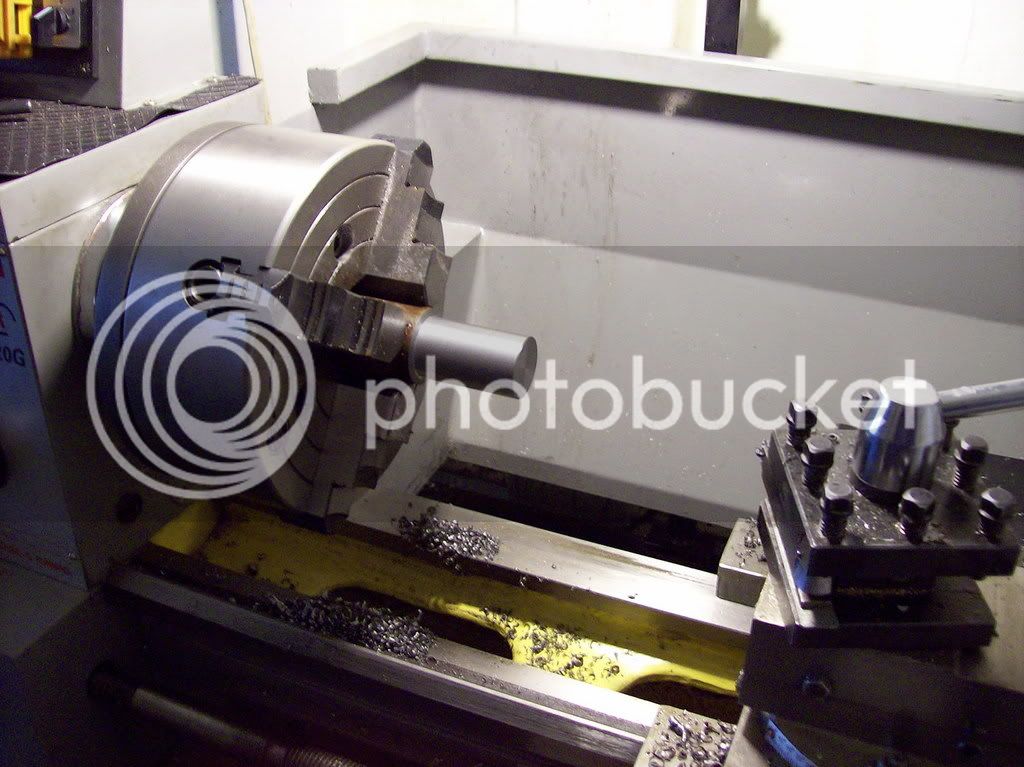

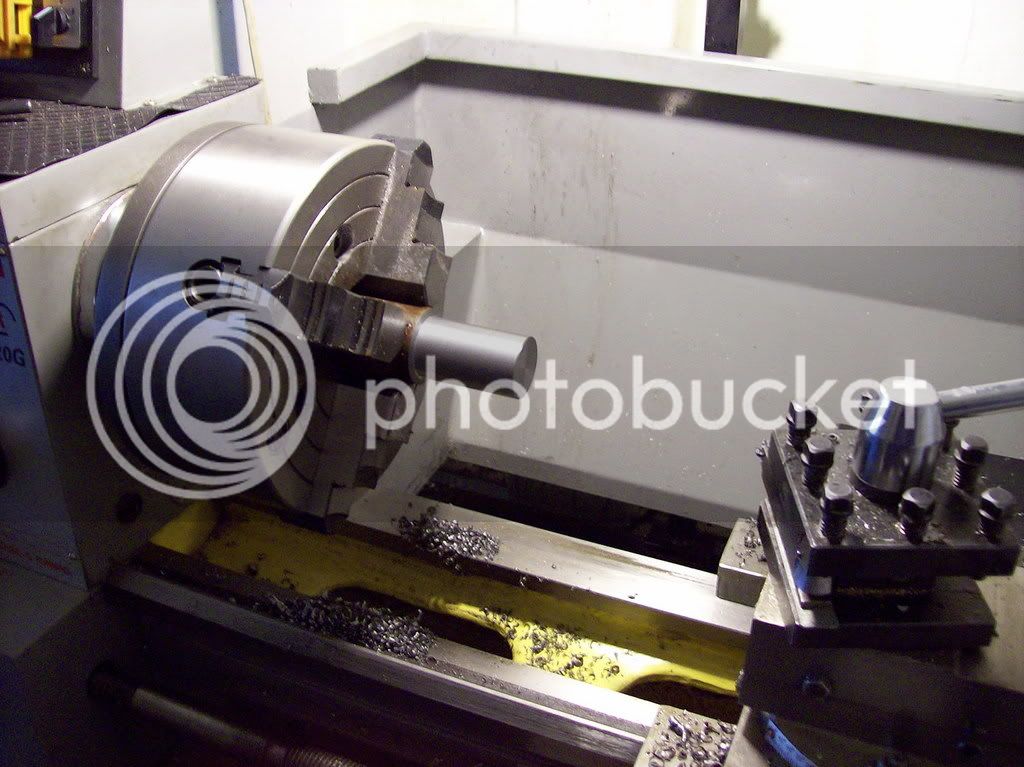

The MS Cylinder chucked and machined down to a known dia, (1-1/4"), - makes it easier to centralise the rectangular cylinder base which sits on the rectangular top of the crankcase.

If I'd kept going I would have wanted to finish the cylinder OD but that tomorrow's job.

SWMBO had no plans for me today, she and our credit card are recovering from another city trip. I almost managed a full day on the engine but stopped at a point where if I had continued I would still be in the shop. I'm sure you know what I mean.

On with the saga - I managed to make and fit the Crankcase end cover and make a start on the Cylinder.

Slide show follows

After the initial machining - checking the fit of the crankcase on the end cover.

Machining the outer face

The outer face counter bored

Marking out the end cover for the stud holes

Drilling the stud holes

Using the end cover as a template for the stud threads in the crankcase

Tapping the crankcase 6BA and Oh so easy to tear a thread out in Alu!!

Phew the studs are fitted

The crankcase with the end cover in place.

The MS Cylinder chucked and machined down to a known dia, (1-1/4"), - makes it easier to centralise the rectangular cylinder base which sits on the rectangular top of the crankcase.

If I'd kept going I would have wanted to finish the cylinder OD but that tomorrow's job.