raveney

Well-Known Member

I go to this show every year

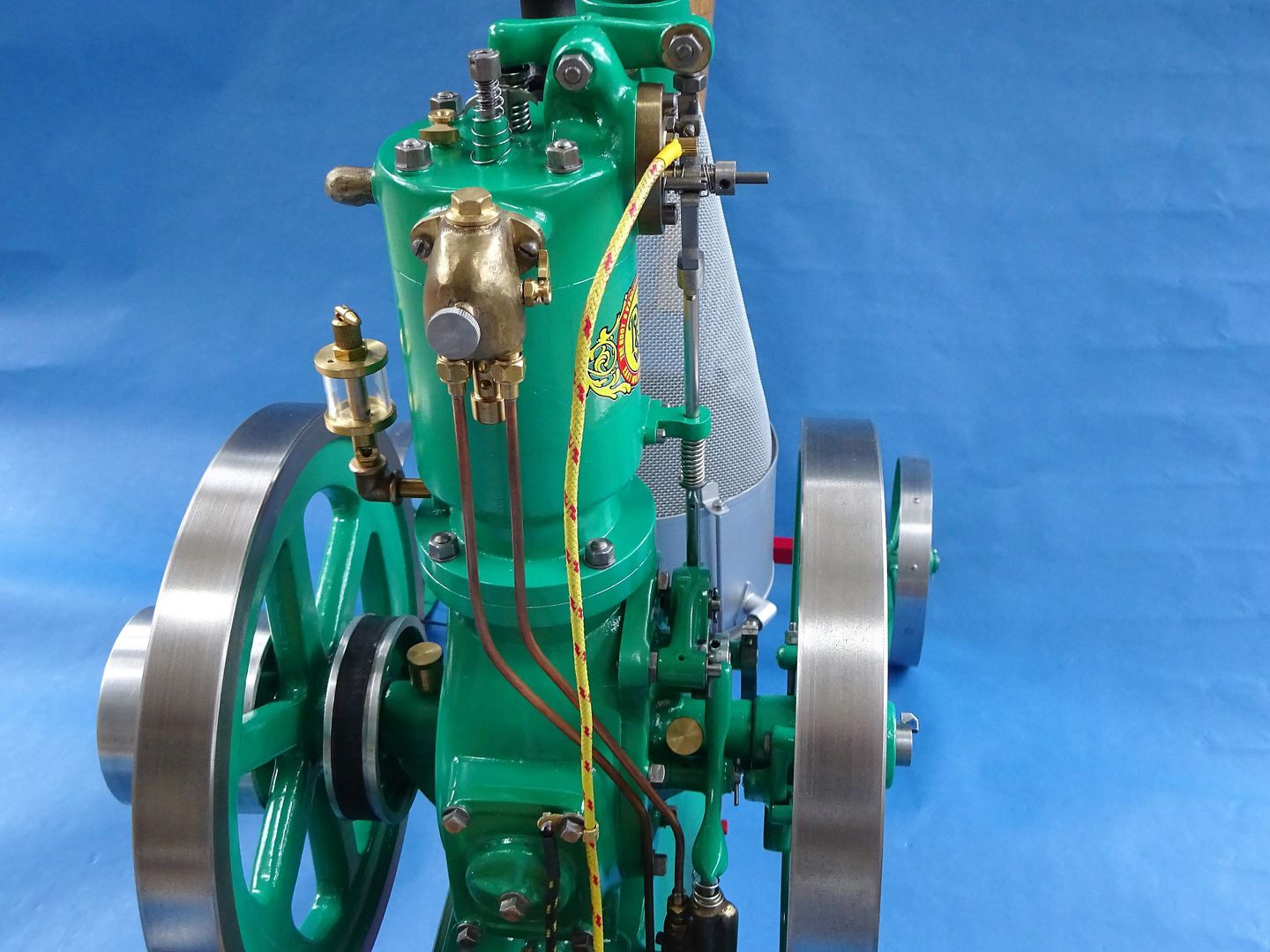

Its overcast and mid 70 F today here in central Florida. Mostly real hit and miss engines, antique tractors etc. Very useful to me to see real size ones. They have an operating 1916 Case tractor which I used as a reference when building the well known Rudy's Tractor model. I have a build link. This year I want to focus on vertical engines and screen coolers and will share some pictures of today's trip.

https://floridaflywheelers.org/events/

Its overcast and mid 70 F today here in central Florida. Mostly real hit and miss engines, antique tractors etc. Very useful to me to see real size ones. They have an operating 1916 Case tractor which I used as a reference when building the well known Rudy's Tractor model. I have a build link. This year I want to focus on vertical engines and screen coolers and will share some pictures of today's trip.

https://floridaflywheelers.org/events/