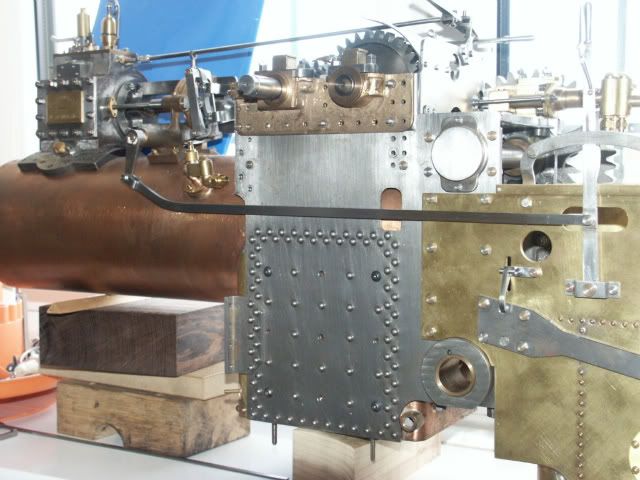

Well it seems that the last month or so has been spent turning lengths of bronze and brass bar into an expensive pile of swarf as I have been working my way through the various bits of plumbing on the Fowler. All the parts still need to be buffed up but I will leave that until painting time.

First up were the two cylinder draincocks which have to be fabricated to get the correct angle.

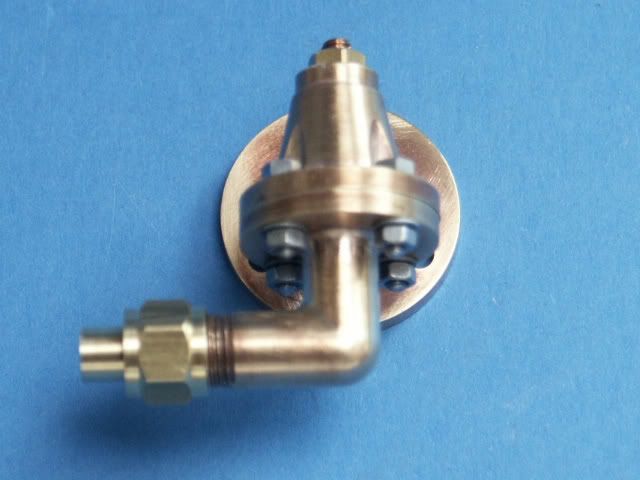

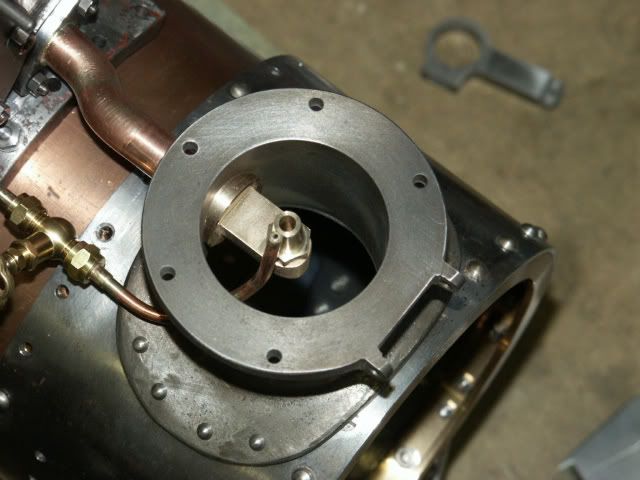

Next was the waterlifter, the ball turner was put to good use on the "T" joint and the elbow is fabricated. I went for a drilled tubular strainer rather than the gauze spec'd on the drawings

The displacement lubricator and pump clack were both similar fabrications

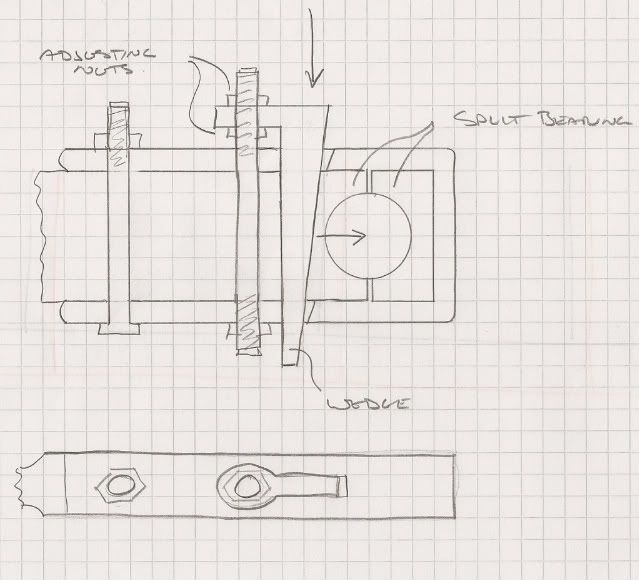

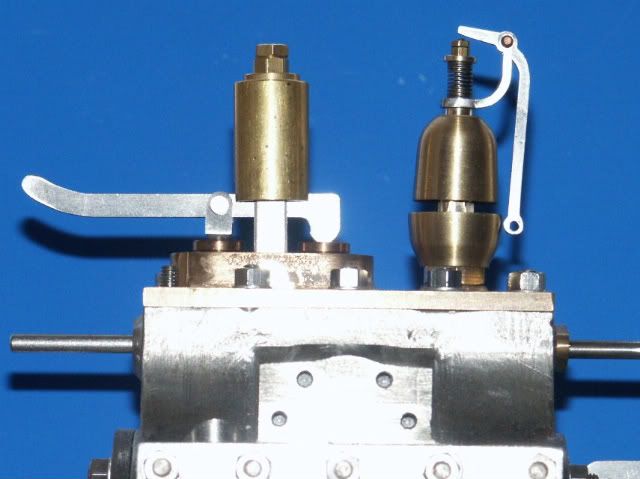

For a break from the pluming I then tackled the governor, balls are again turned from solid rather than joining commercial ones to the arms. I will probably up the 10BA grubscrews that hold the pully & gear to the horizontal shaft to 8BA as its hard to tighten then with such a small slot. Gears are from MJ and just need a little work as they are stock gears.

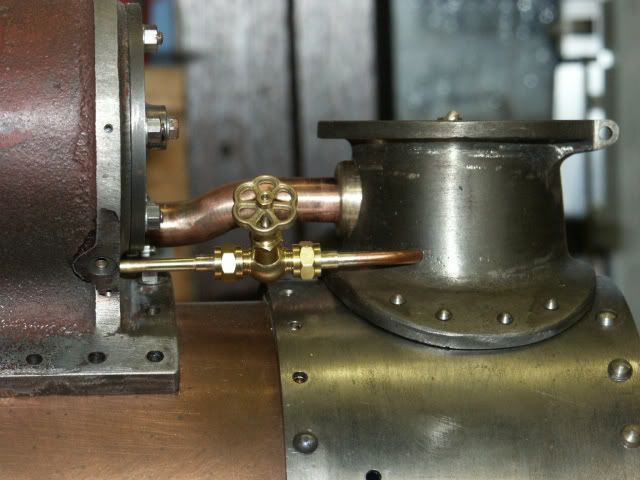

Back to the plumbing and the last casting left to be machined was the manifold, I intend to take the watergauge top feed from one of the bolt holes as the drawing has it off the manifold face which is now not allowed. Can't take credit for the globe valves they are from

Steamfittings

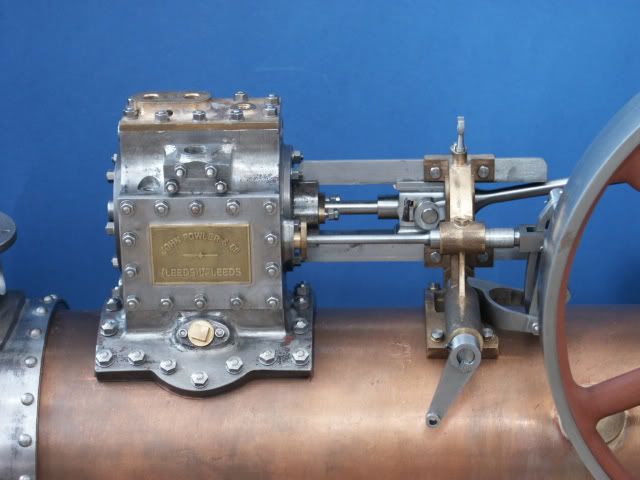

This is the back end of the pump, just need to do the tapered spindle for the tap.

The brass bits for the whistle are done, was just waiting for some 1/16 stainless rod for the valve which has now arrived.

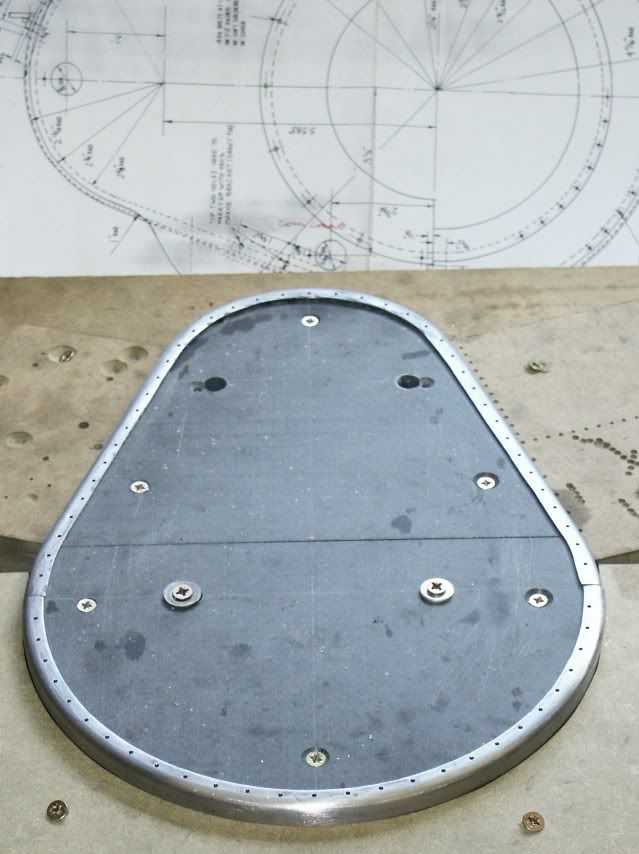

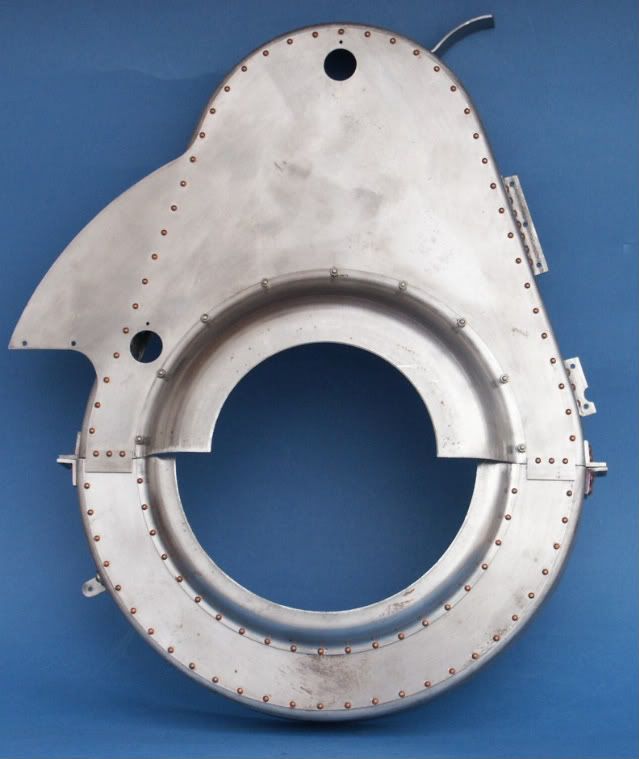

I also bashed out the ashpan over a hardwood former and silver soldered on the mounting flange. I opted for stainless steel hinges etc rather than the mild specified.

And lastly for this update the cylinder is now bolted to the boiler, I turned up bolts from stainless hex with a dimple on the end to look like studs.

Jason