Superb progress here! This is what I have been waiting to see.

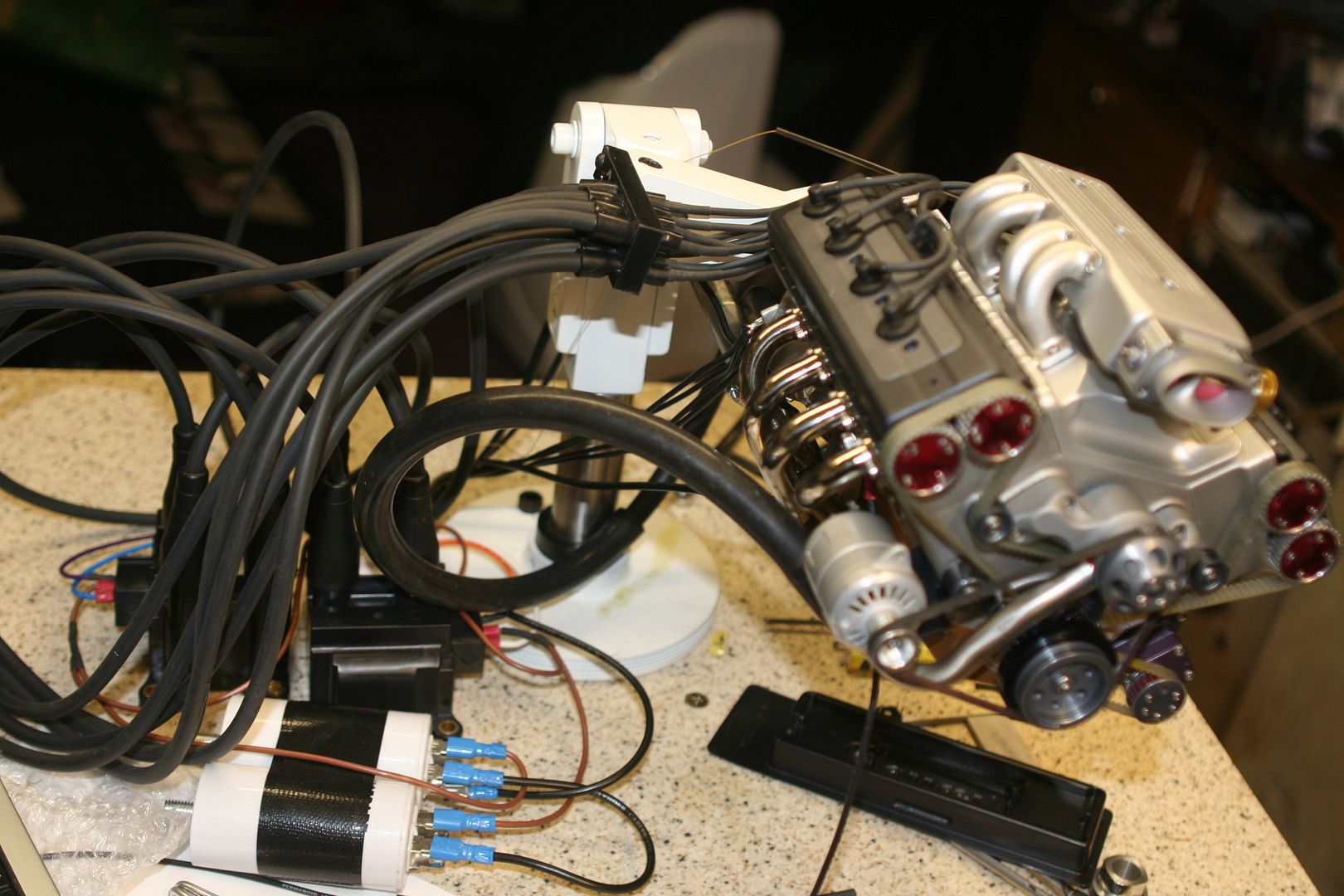

Keith, what made you fit the tube in the path of the injector? I wonder how it would run without that. Seems to me that there is sufficient runner surface and intake tract for fuel to stick to (and keep your engine running for many revolutions after the injector pulse), that adding this tube in the airway might only serve as an air restriction and the extra atomisation might be of little consequence. Or I might have completely misunderstood, what to you think?

Also, how are you pressurising your fuel?

Keith, what made you fit the tube in the path of the injector? I wonder how it would run without that. Seems to me that there is sufficient runner surface and intake tract for fuel to stick to (and keep your engine running for many revolutions after the injector pulse), that adding this tube in the airway might only serve as an air restriction and the extra atomisation might be of little consequence. Or I might have completely misunderstood, what to you think?

Also, how are you pressurising your fuel?