Lakc

Well-Known Member

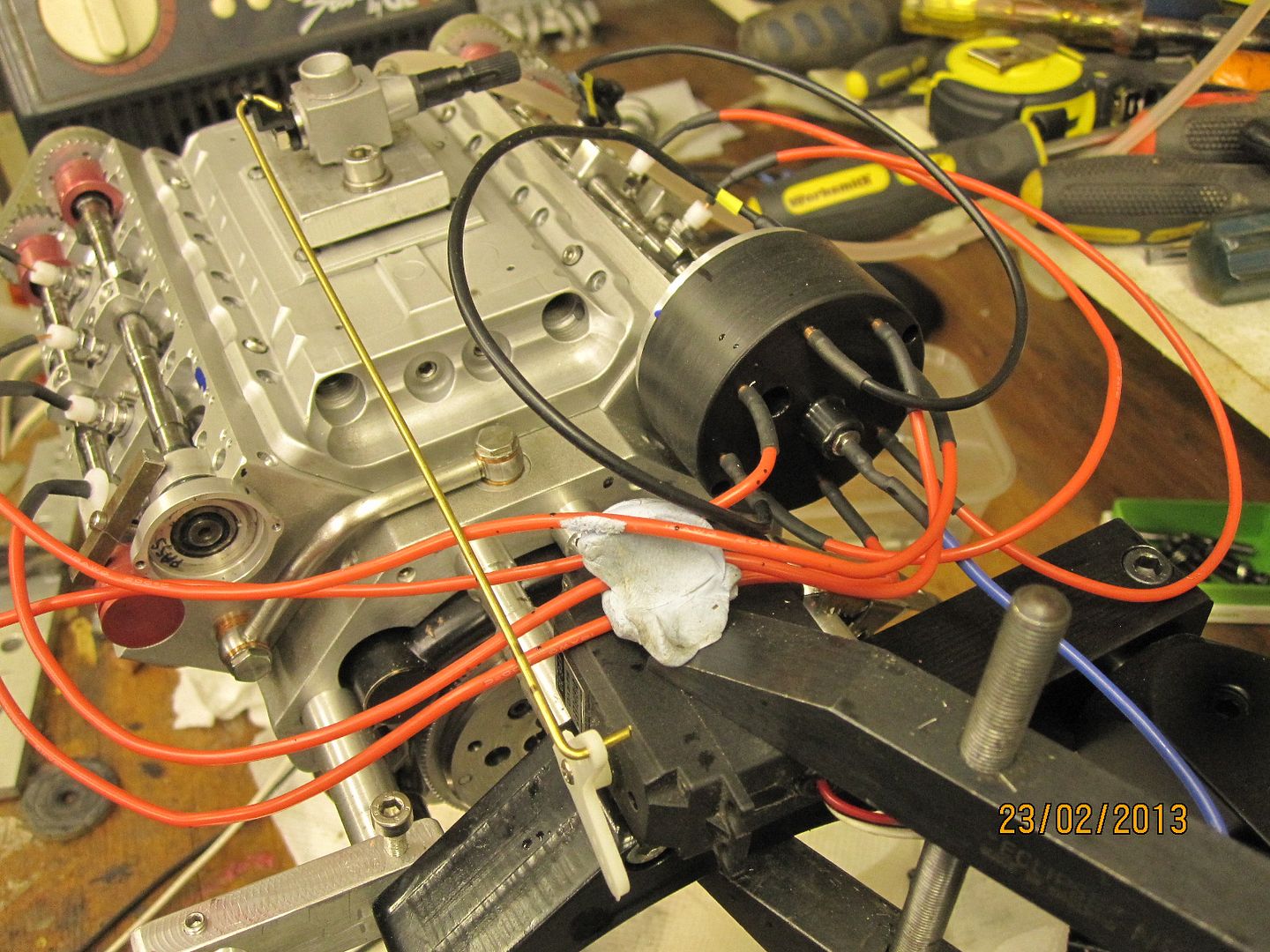

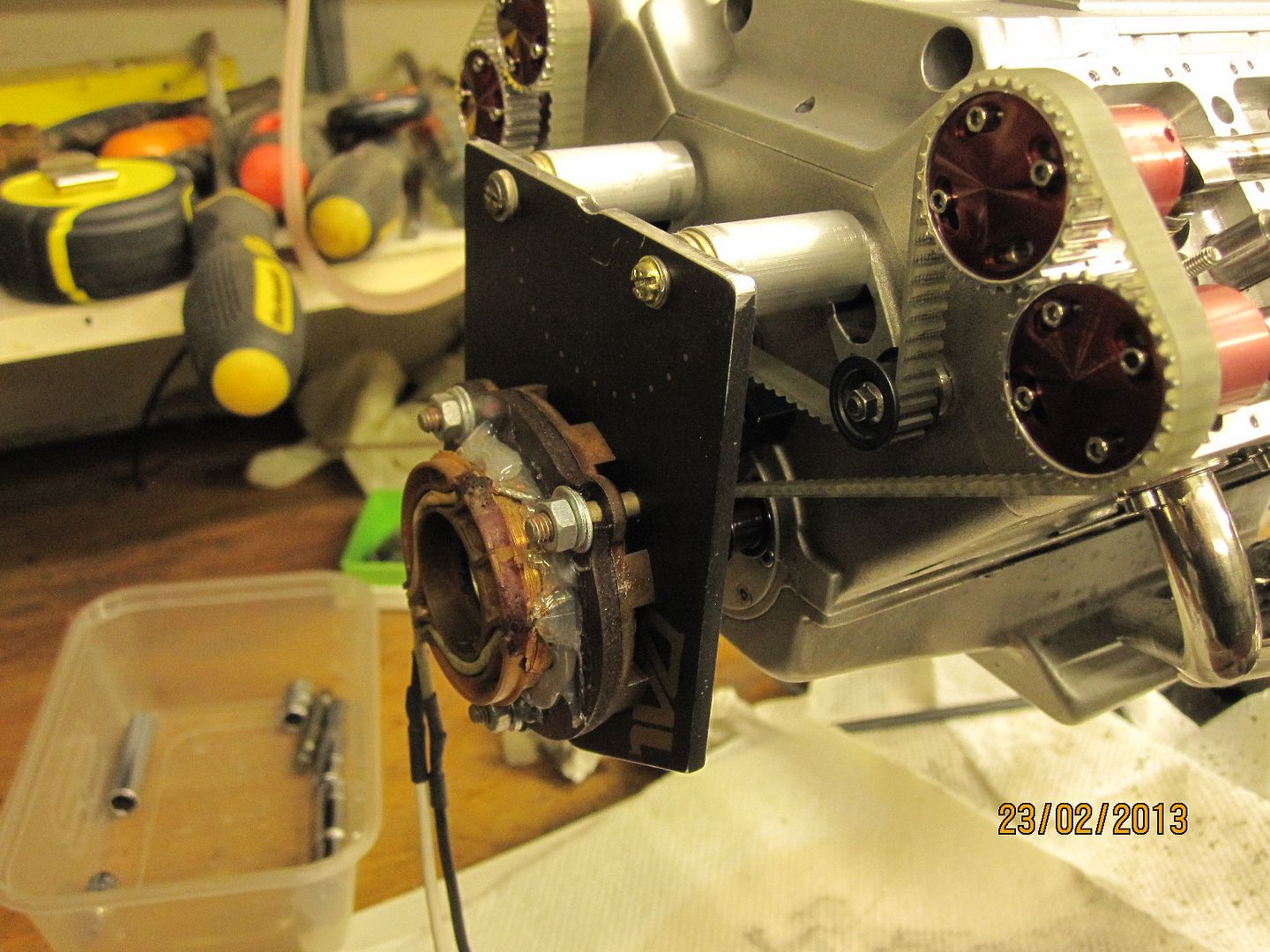

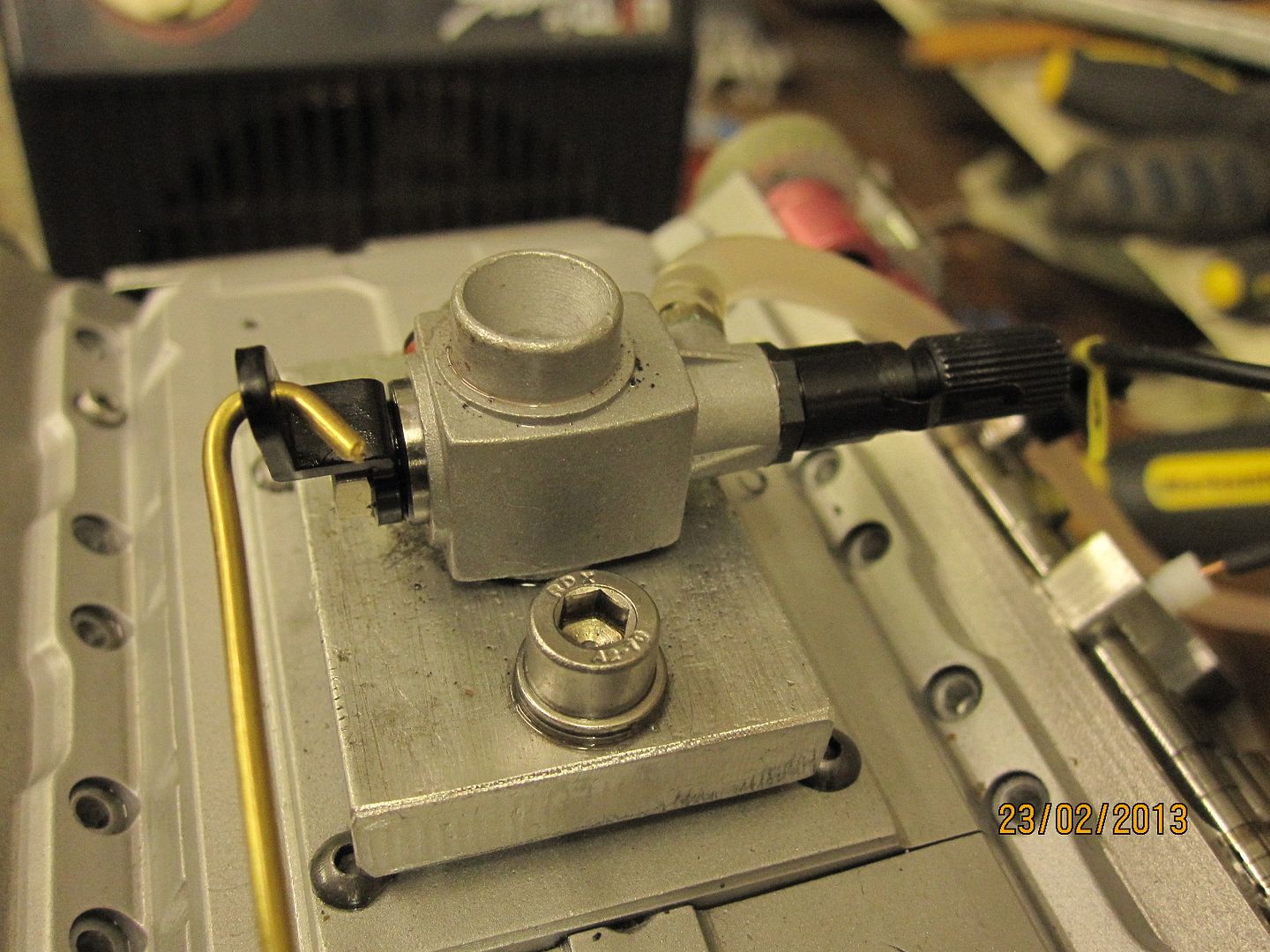

The modules with advance curve have additional pins attached to them, and you usually wont find them in distributors with a vacuum advance.As the GM pole piece is nothing more than a coil of wire around an armature with a poled magnet running inside, why not just use four magnets in the flywheel and a small coil of wire for the pickup?

This could make it a simple crank trigger system, and the pickup coil could be slotted for timing adjustments. The GM ignition module has an advance curve built into it but that is a whole new subject.

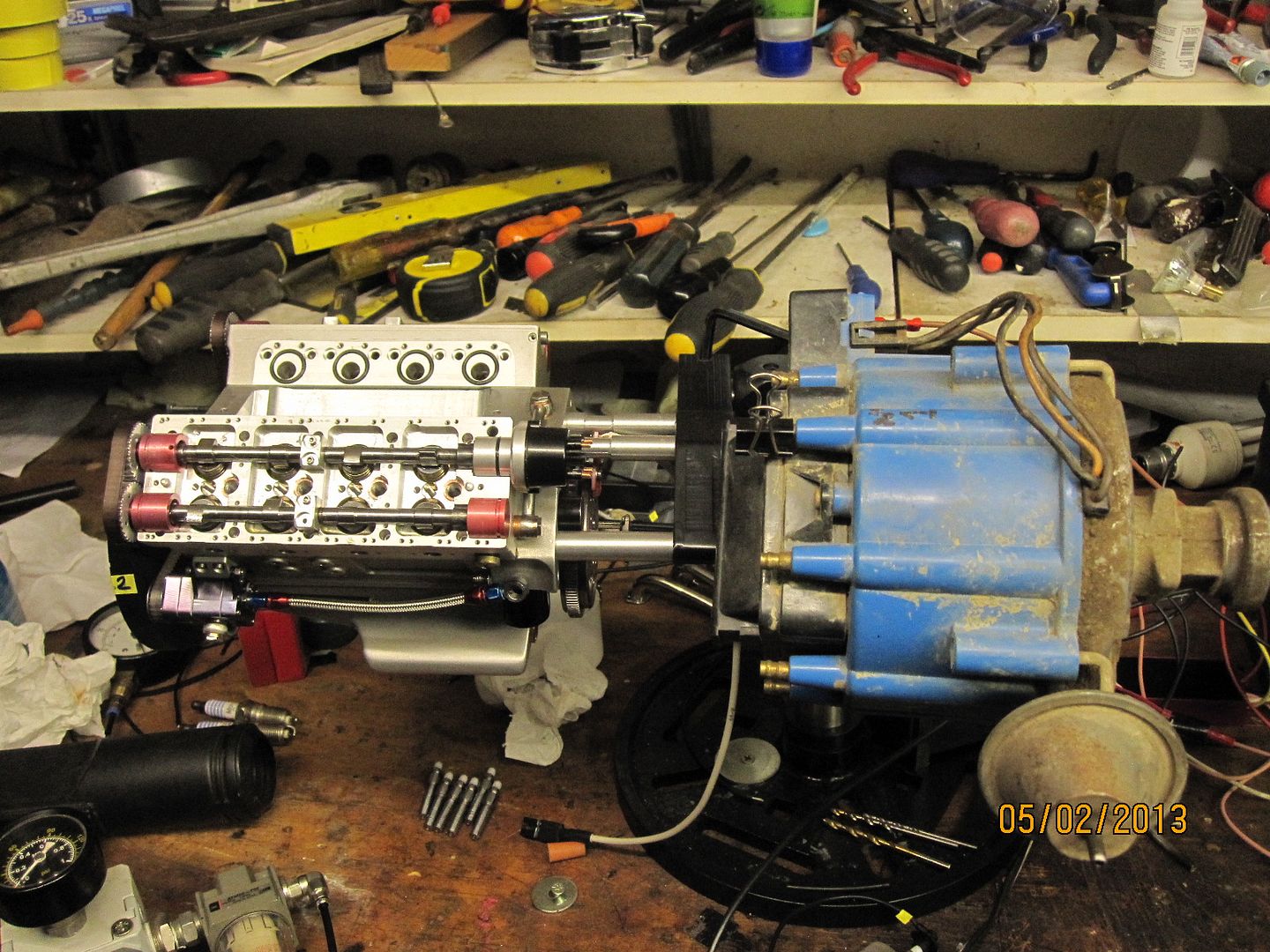

With two distributors, and only one coil to feed them, you may be able to use a Y coil wire. One distributor should lag the other by 45 degrees and the spark should travel to the side with the least resistance. It may work as a demo but I wouldnt design something like that on purpose.