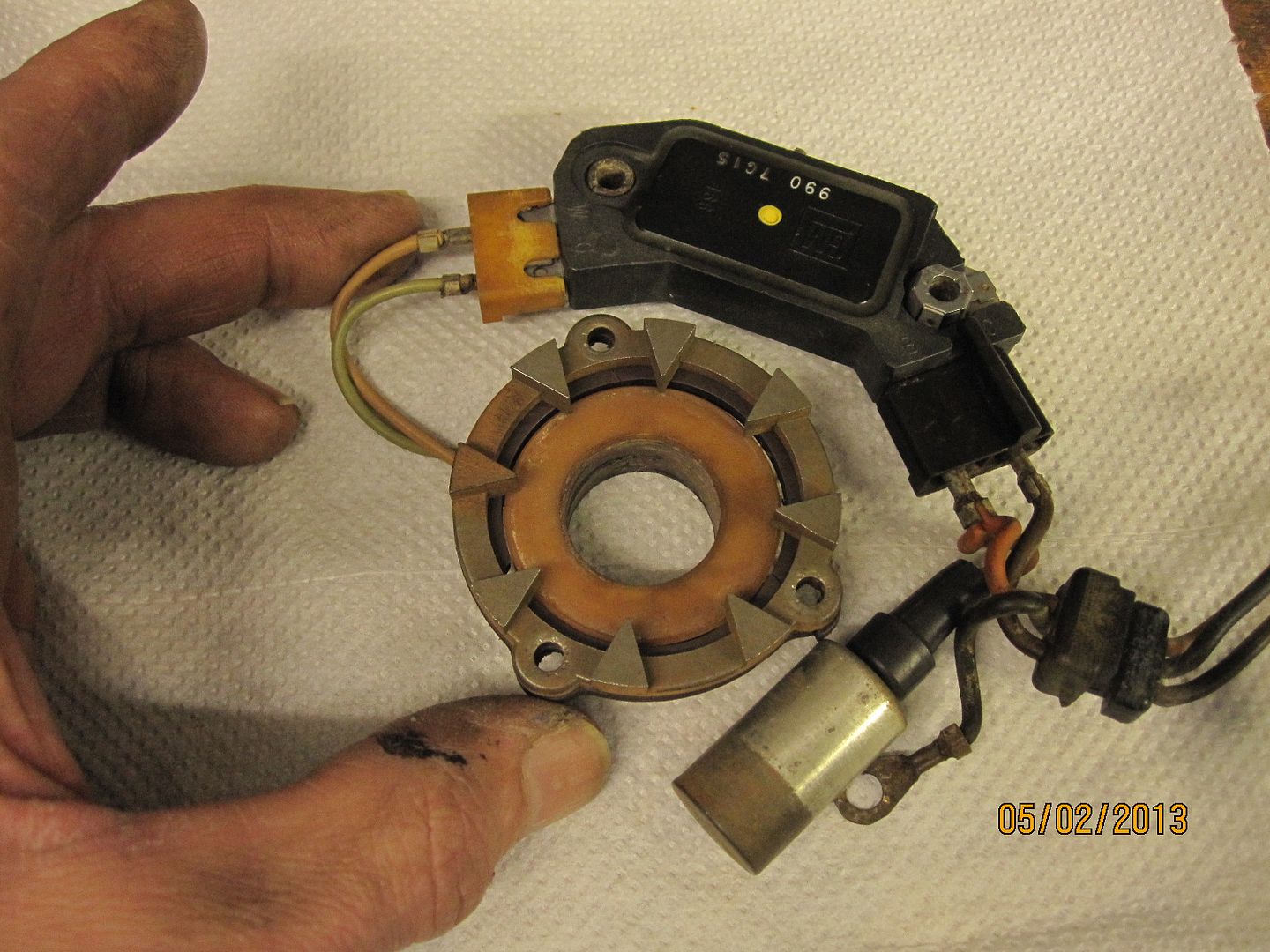

Thats the factory GM module, you can lick one finger and put it on the battery positive and touch your other hand to one of the reluctor terminals and it will spark. For a good test you can just move an electric engraver next to the reluctor coil and it should spark all day. If you do decide to do some heavy testing with that module. you need to have it mounted with heatsink compound as it sinks from the bottom.

Thats one of the first generation electronic ignitions, and one of the best ever made. It only needs 5 connections, B+, ground, negative side of the coil, and both sides of the pulse generator (reluctor). It takes about a volt and a half to trigger, and only pays attention to the positive pulse, so you can literally run it off a hall sensor if you like.

When a coil misfires or arcs internally because of too high external resistance it will start to carbonize the materials it jumps across. This carbon tracking will eventually look like a short to a spark and of course it takes the easiest way to ground. Your ebay coils were probably half shot through, and when they needed to fire under load the existing carbon tracking was an easier path.