Thank you, all comments gratefully recieved, even if I don't reply straight back.

Art, I will run it as is firstly. It may be that gearing up the pump 30% may be enough. However, it may need 10x more flow, in which case a different pump will be required, so I'll try it first.

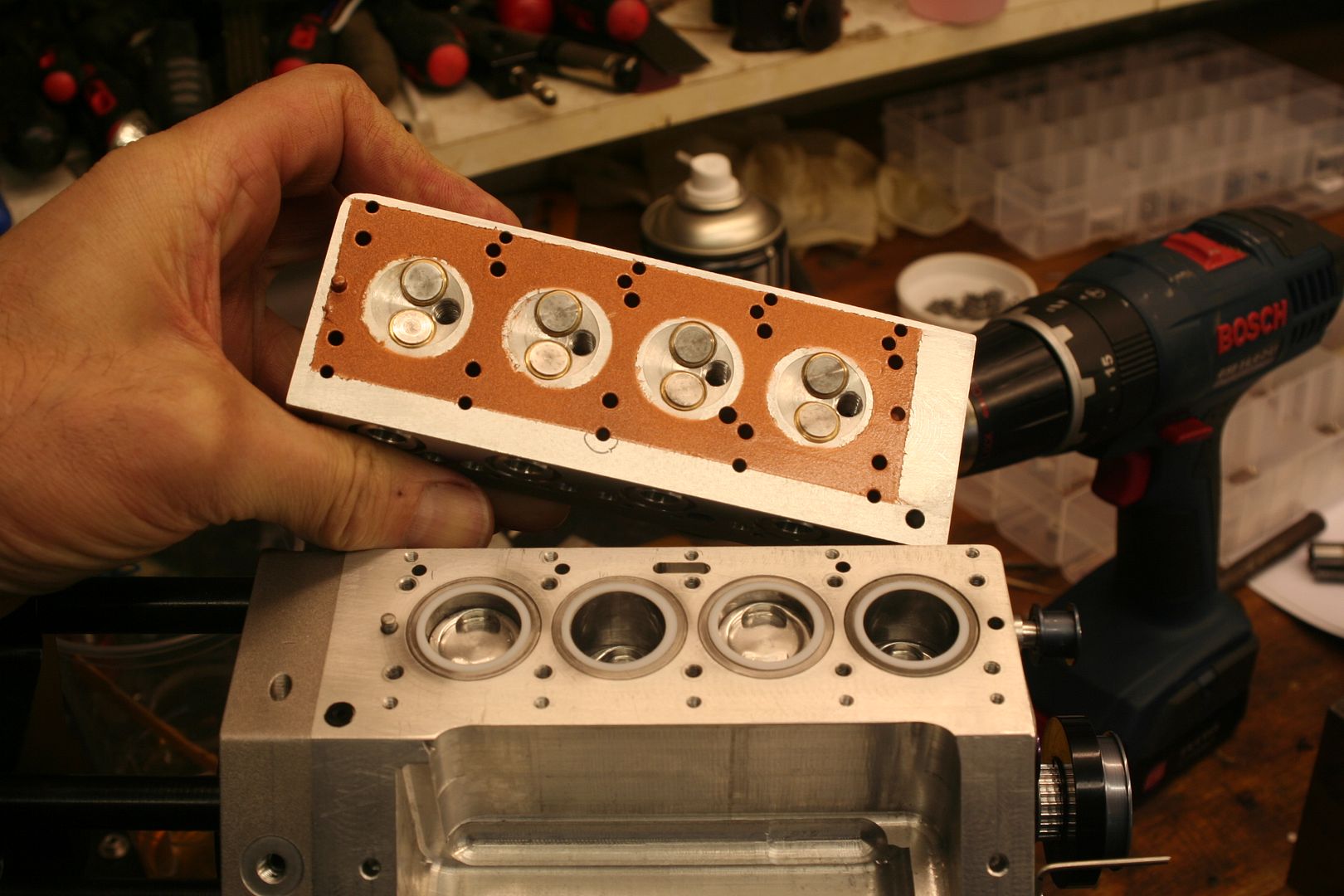

Bringing myself up to date now. Missed this photo showing the spray on head gasket and ptfe cylinder liner gaskets. The ptfe will crush up 4 thou with the heads on, so time will tell if they stand up to running.

I was planning on using full head gaskets, but there was no room for water bores in the new inlet manifold, so the plan is to rely on the cylinder cooling to cool the heads too. To make this work better though I wanted the head to contact the block without any insulation between.

Please don't copy this idea until I've tried it, it may be rubbish.

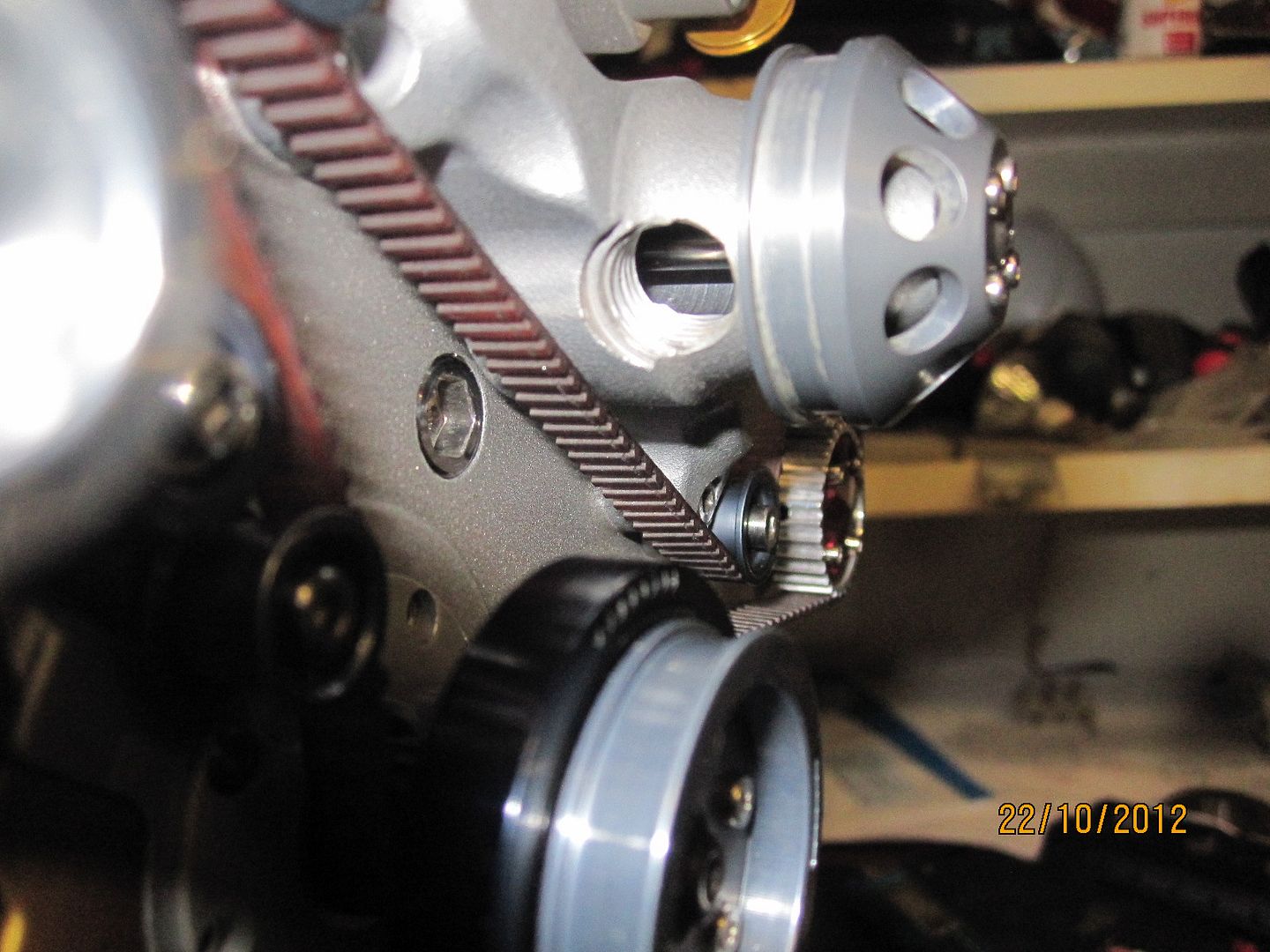

Exhaust header flange. More pics later on this..

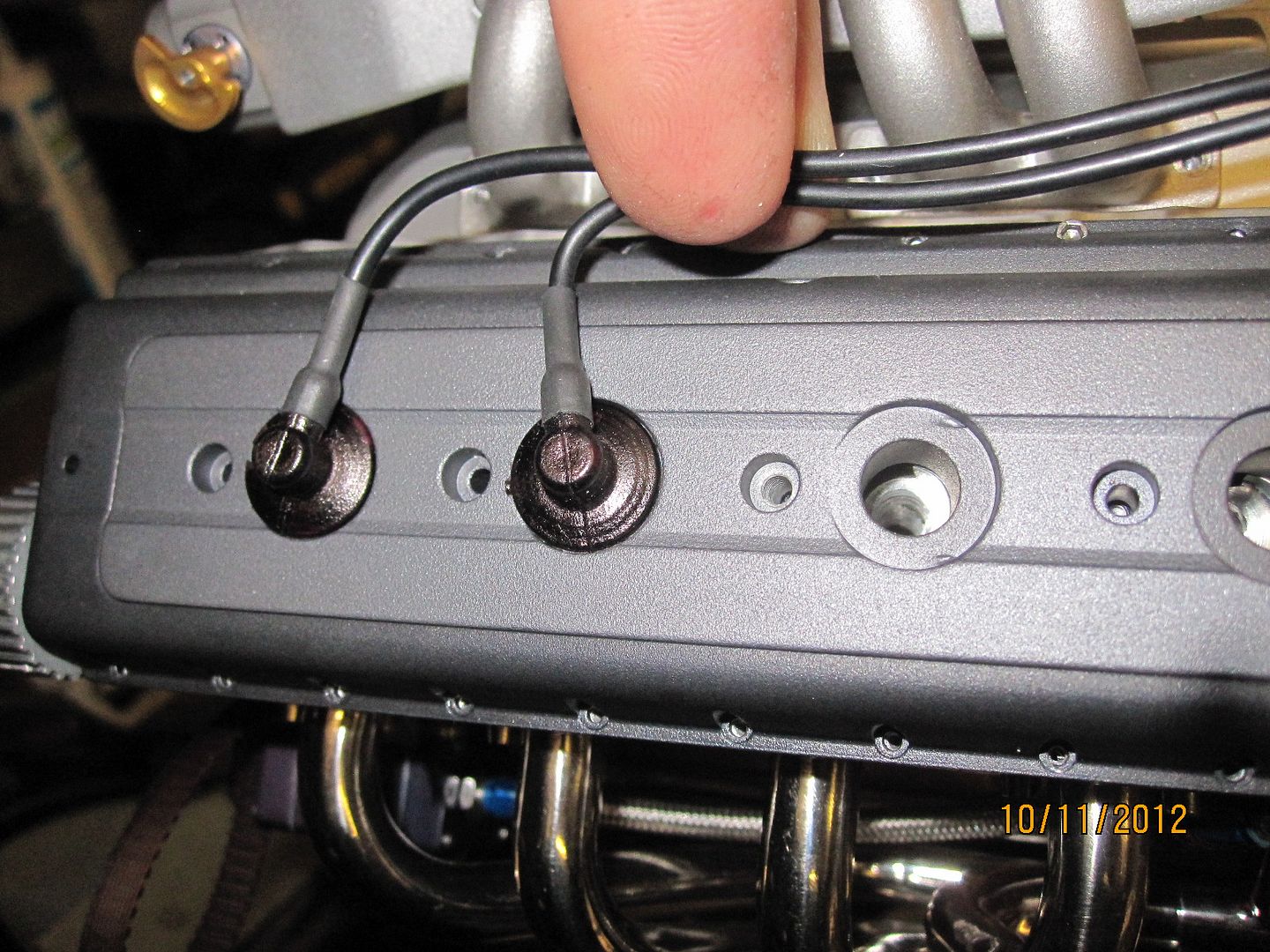

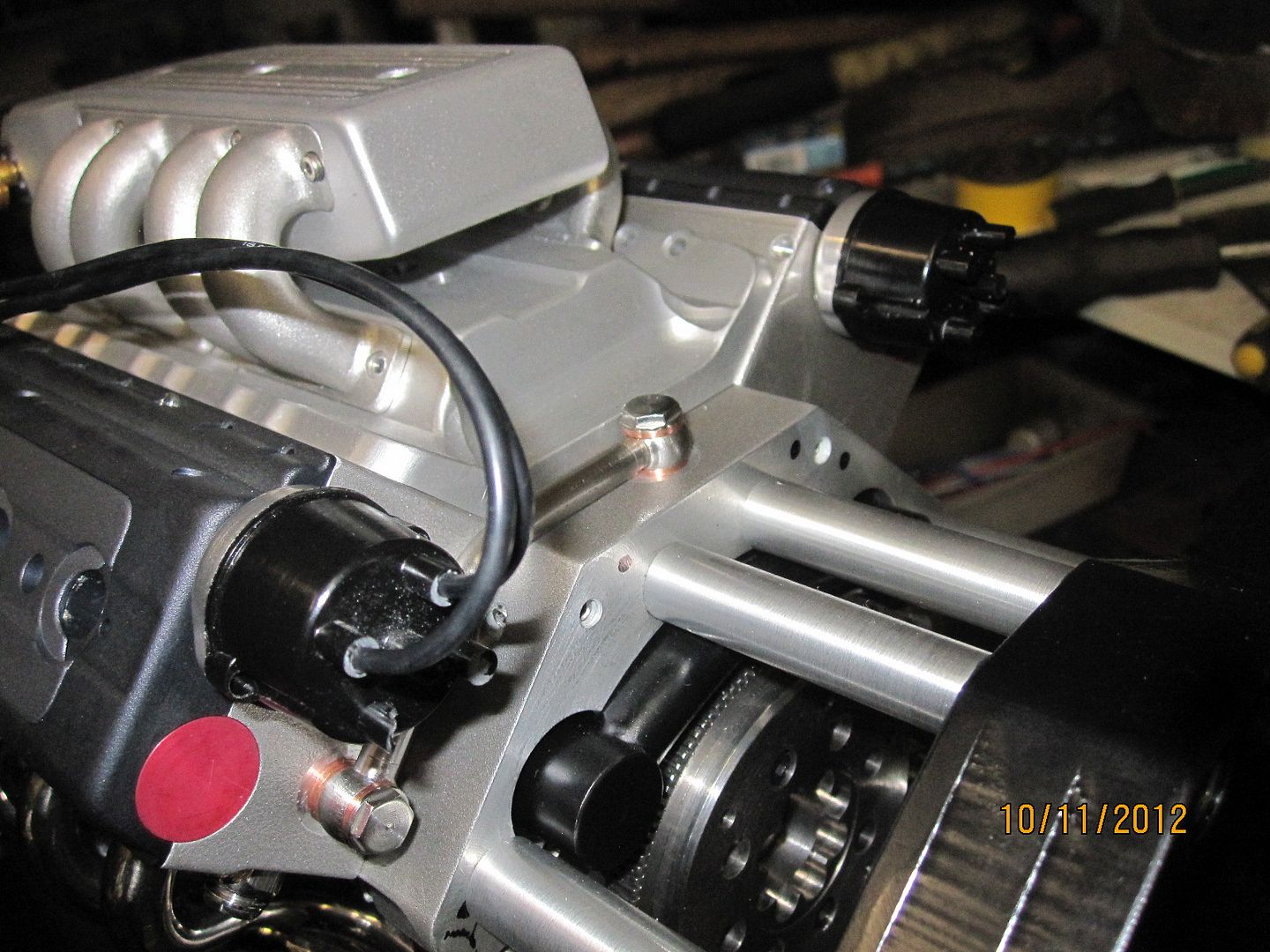

Spark plug caps, polyurethane mouldings. Not managed to cast a bubble free one yet!

I decided to try an cast the dizzy caps at work. We have some hard polyurethane stuff which looks perfect for the job. Turned out to be more difficult than I thought.

This is the mould..

And this is the result so far. I need to re-design the mould and inject the poly under pressure,(syringe).

Actually I'm not too bothered with the bubbles as I don't really like these shaped dizzy caps on the end of the heads. I'll try and draw up a side mounted ht lead version.

Thought I'd try them for looks though...

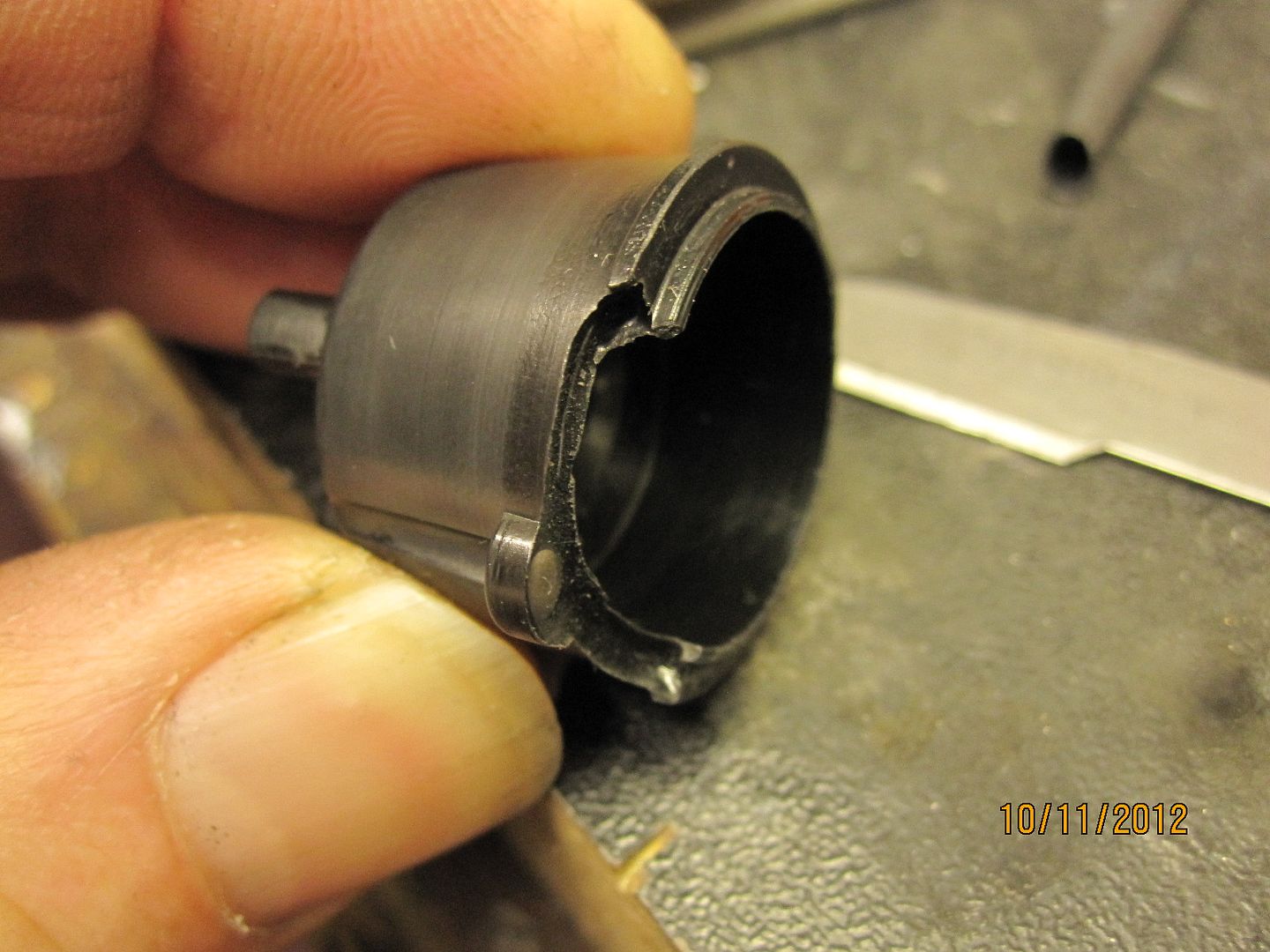

Got bored with the caps so had a go at a spark plug.

I found some ceramic tube on ebay, 3.5 o/d and 10mm long. This is pushed in to the hot end and the rest is ptfe tube. Can't really afford the macor, although that would be ideal.Cut the M6 thread with a die but the pitch was half a thread out in 20mm so won't go in the head.

Need to threadcut these then.

Also got no mechanical way of keeping the electrode in so need some high temp adhesive.

Given up for the day!