T Mihelich

Active Member

- Joined

- Jan 9, 2010

- Messages

- 37

- Reaction score

- 19

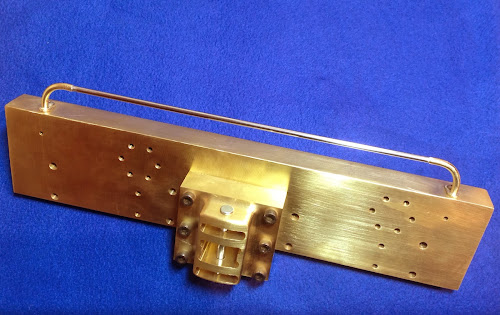

Well i got it guys.

There is using brake clean and there is USING brake clean! :big:

Seems spraying it directly on it vs a wipe rag did the trick.

Frame #1 is completed and shining nicely.

On to Frame #2.

There is using brake clean and there is USING brake clean! :big:

Seems spraying it directly on it vs a wipe rag did the trick.

Frame #1 is completed and shining nicely.

On to Frame #2.