Today I received my one way clutch bearing in the mail. It looks exactly like a sealed ball bearing, but it definitely has the "turn only one direction" feature. I am going to mount it in the offset weight arm, so that as soon as the engine has lifted the weight arm over the top, the arm will swing back down due to gravity, and having no "binding force" transmitted back to the engine.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Verical hit and miss engine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The one way clutch bearing had an inner diameter of 12 mm, so I made a hub of cold rolled steel, put two set screws in each end and drilled/reamed it 0.312" for the 5/16" shaft it is going to mount on. The hub is pressed into the bearing with an interference fit of .0005".

Well, the one way clutch bearing works exactly as advertised. I'm impressed. However--the set up didn't work. The one way clutch bearing was mounted in the steel bar which gets rotated, but--Once the bar goes slightly past vertical, it free swings thru almost 350 degrees. The engine has to hardly work at all. I thought for a moment that I had invented perpetual motion.

-I am going to either give up on this or try a totally different approach. The absolute best video of the engine hitting under load and missing under no load was the video in which the string with a weight on one end went over a pulley and down to a small winch drum attached to the clutch. My current system with the worm gear gives the engine too much mechanical advantage--it never sees enough load to function the way I want it to. In a perfect world, the winch drum would turn clockwise for a measured number of turns, then stop and turn counterclockwise for a measured number of turns. I want this loaded and unloaded cycle to repeat, with no intervention from myself. I actually have enough ceiling height to put the top pulley that the string goes over up higher, and have something attached to the string running down to the weight in two places. At the upper and lower limits of travel, the "thing" attached to the string would move a lever, which would reverse the drum rotation. I have looked at all manner of "automated reversing systems" and they either beyond my machining capabilities, or look like they wouldn't work. I am in no rush to build another engine, so am still searching for an automated reversing system that looks like i could build it. There is one in the booklet "507 Mechanical Devices" that shows promise, but it would be a lot of work.

Today I received my one way clutch bearing in the mail. It looks exactly like a sealed ball bearing, but it definitely has the "turn only one direction" feature. I am going to mount it in the offset weight arm, so that as soon as the engine has lifted the weight arm over the top, the arm will swing back down due to gravity, and having no "binding force" transmitted back to the engine.

Where did you get this bearing/clutch? I want to use one to put an electric start on a 4 stroke model airplane engine. Hooking up a small electric DC motor with appropriate reduction on an unused transmitter channel with this type of clutch would let the DC motor drive the gas engine but prevent the gas from driving the electric motor once it starts..

Of course driving a simple DC motor would produce a dynamo that could be used for on board power and reduce the need for heavy high power radio/servo batteries. Just need a small battery for electrical ballast and drive the servo load from the generator. Hmmmmmmm.

Purchased from Bearings Canada

CSK12-One-way-Sprag-Backstop CSK12 One way Bearing Sprag Freewheel Backstop Clutch:One Way Bearing

1 at $25.34

CSK12-One-way-Sprag-Backstop CSK12 One way Bearing Sprag Freewheel Backstop Clutch:One Way Bearing

1 at $25.34

I’ll check it out. Thanks.

el gringo

Well-Known Member

- Joined

- Aug 30, 2010

- Messages

- 333

- Reaction score

- 175

Nice work Ray. Would you please start a new thread about your build.---Brian

- Joined

- Sep 19, 2015

- Messages

- 274

- Reaction score

- 80

Hi Brian quick question.

Would any thing be gained by removing the inside seal from the crankshaft bearings seeing they will well and truly be splash lubed.

The bearings I have bought are very gummy stiff feel to them as though they are packed with heavy grease.

Cheers

John

Would any thing be gained by removing the inside seal from the crankshaft bearings seeing they will well and truly be splash lubed.

The bearings I have bought are very gummy stiff feel to them as though they are packed with heavy grease.

Cheers

John

Cogsy

Well-Known Member

John, Brian is probably in bed at this time so I thought I'd respond. Bearings running with a splash oil system will run with far less friction than in grease. Your only problem might be the seal quality of the bearing - with only the outside seal left, and if there's lots of oil getting fed to the bearing, then it might weep oil from the seal. Then again, our engines always need a clean up after a good run so I'd say the definite gains outweigh the possible drawbacks. Rip those inside seals out and rinse the grease out, then add a couple of drops of light oil to protect them until your engine suns and supplies its own oil.

- Joined

- Sep 19, 2015

- Messages

- 274

- Reaction score

- 80

Thanking you.

I left the seals in both sides of my bearings. I thought about pulling the inner seals out, but didn't want to risk it in case it created oil leaks.--Brian

- Joined

- Sep 19, 2015

- Messages

- 274

- Reaction score

- 80

Thanks Brian I'll leave them in and see how it goes.

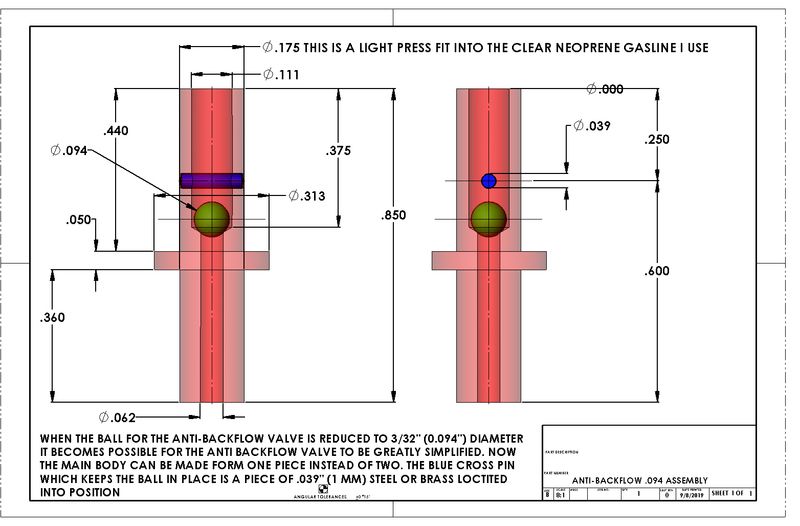

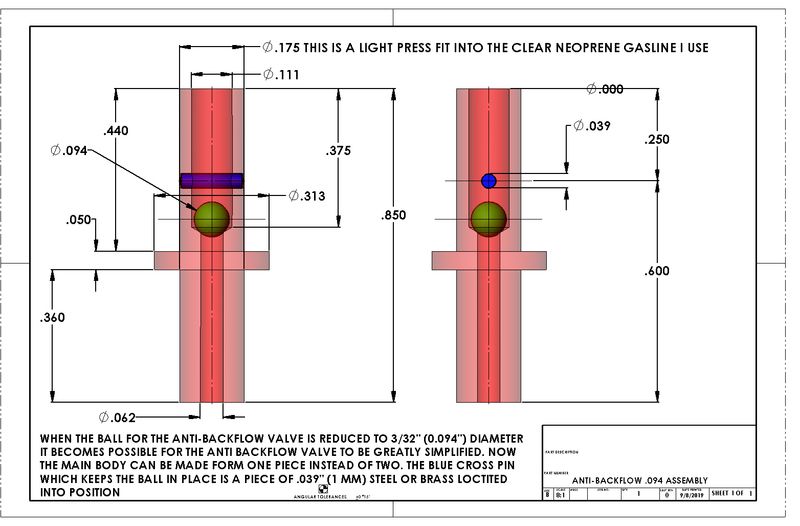

After much playing about with this engine, under both load and no load conditions, I have come to notice this phenomenon that I have seen before on other hit and miss engines. When the engine is running very slowly, with a good number of "misses" between "hits", the fuel in the line running to the carburetor wants to all run back down in to the tank during long "miss" cycles. Then when it finally does "hit" again, there is no fuel at the carb and the engine stops. I use clear neoprene gas line, and I can see it doing this. The answer of course is my venerable one way valve, as shown in the .jpg. This one way valve only works well in the vertical position, and the best location is immediately below the carburetor fuel inlet. Experience has shown that a 3/32" diameter ball is the optimum size. If the ball is larger, the venturi vacuum from the carburetor may not be strong enough to lift the ball consistently.

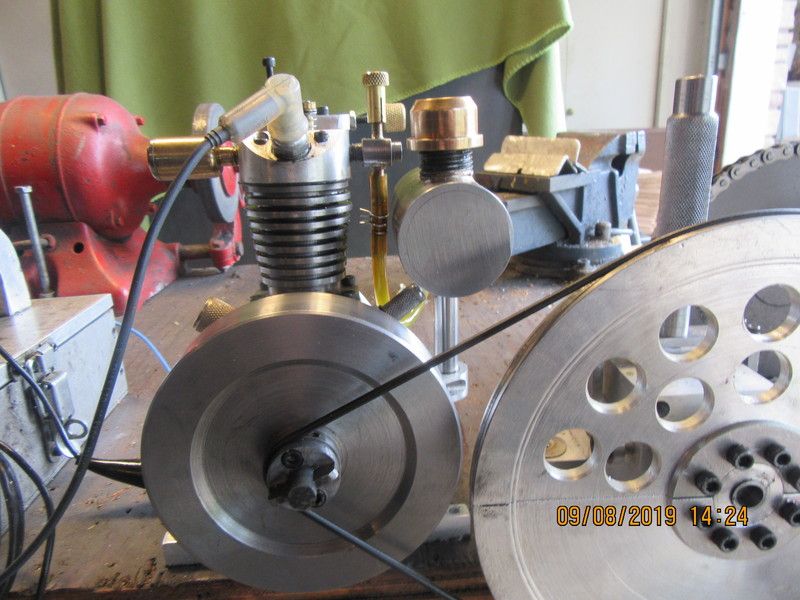

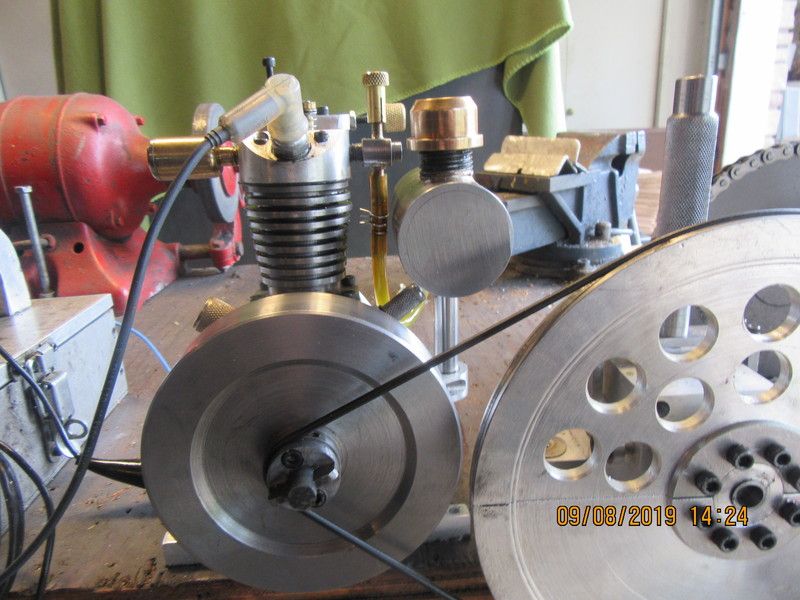

That fixed it!! You can see it setting directly below the carburetor fuel inlet. (there really isn't much to see, because the gas-line pushes on from both ends of it). Now when the engine is on "miss" cycles, the fuel doesn't run back from the carburetor at all. The engine starts a lot easier too, with much less manual choking.--Also of interest to some will be the gear reducer with the piece of tape on the output shaft. I built that reducer about ten years ago, using gears from a couple of dead electric drills. It has an 8:1 overall ratio. That reducer was built back before I purchased my own complete set of 24DP gear cutters.

I'd like to see a short video of that running. I'm guessing the tape goes slower than the engine does.

The engine pulley drives a bigger pulley, which will be slower (RPMs) than the engine. That drives a small shaft which uses a chain to drive a bigger gear which will be slower than the intermediate gear's input. Is that tape running at 1/8 the RPMs of the engine or something much slower, like 1/64 speed?

The engine pulley drives a bigger pulley, which will be slower (RPMs) than the engine. That drives a small shaft which uses a chain to drive a bigger gear which will be slower than the intermediate gear's input. Is that tape running at 1/8 the RPMs of the engine or something much slower, like 1/64 speed?

Bob--lets pick a random number--say the engine is turning 1000 rpm. The initial belt drive from the engine to the clutch big pulley is 8:1 ratio, so the clutch shaft is turning 1000/8=125 rpm. The clutch is a straight thru drive with no gear reduction, so the small sprocket is turning 125 rpm. The ratio between the two sprockets is 4:1, so the big sprocket is turning 125/4=31.25 times per minute. The gear box has an 8:1 ratio, so the output shaft is turning 31.25/8=3.9 rpm. that is why I have the tape on it, to be sure I can see it turning.

Thanks. That's slower than I thought it would be.

Interesting to see it's almost 1/256 of the input.

Interesting to see it's almost 1/256 of the input.

Similar threads

- Replies

- 413

- Views

- 38K

- Replies

- 148

- Views

- 22K

- Replies

- 5

- Views

- 2K

- Replies

- 6

- Views

- 784