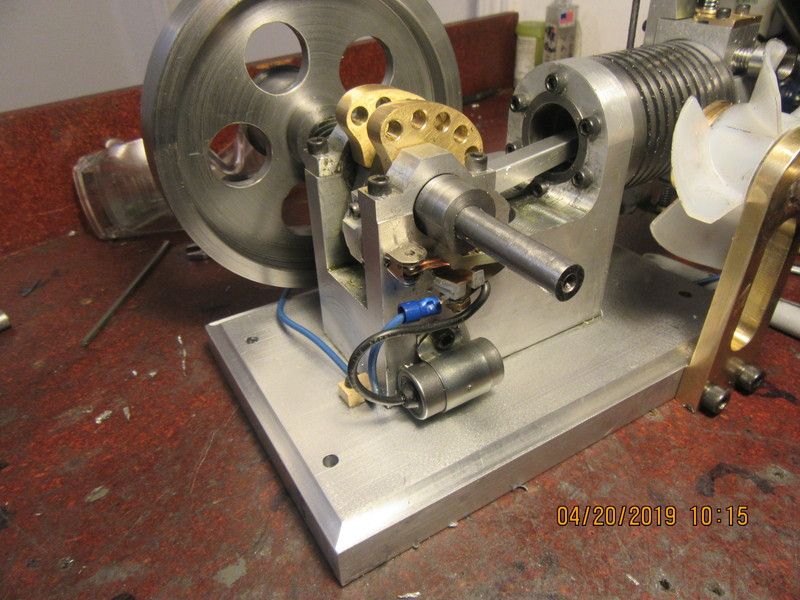

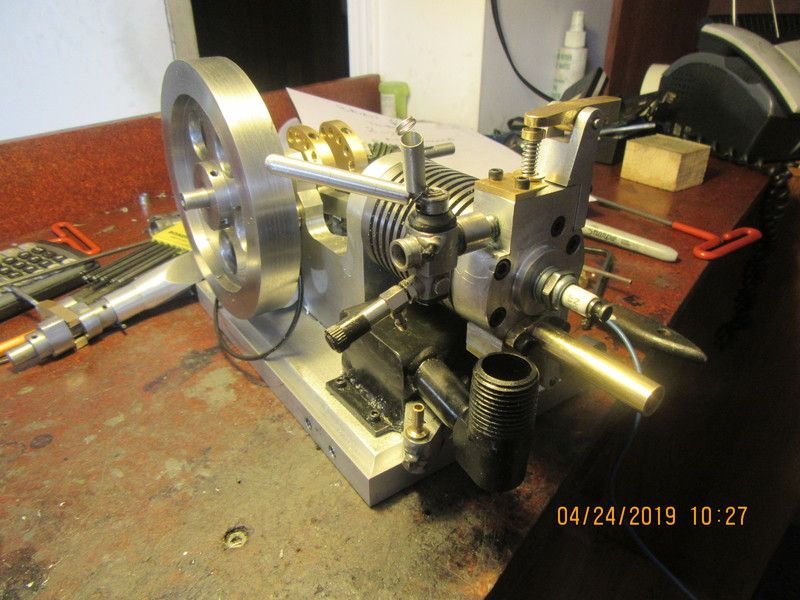

Of course, like all my i.c. engines, I have to have a starter hub. This hub will bolt to the face of the flywheel. Since the crankshaft is relatively small on this end (0.3150") I want to keep any torque forces from outside to be as close to the supporting crankshaft bearing as possible. I will probably make this up today. Also you will see at the far end of the engine a red wire clamp. I don't have it correctly positioned yet, but it is there to hold the "hot wire" which goes to the ignition points so that it doesn't rub on the flywheel and short out.