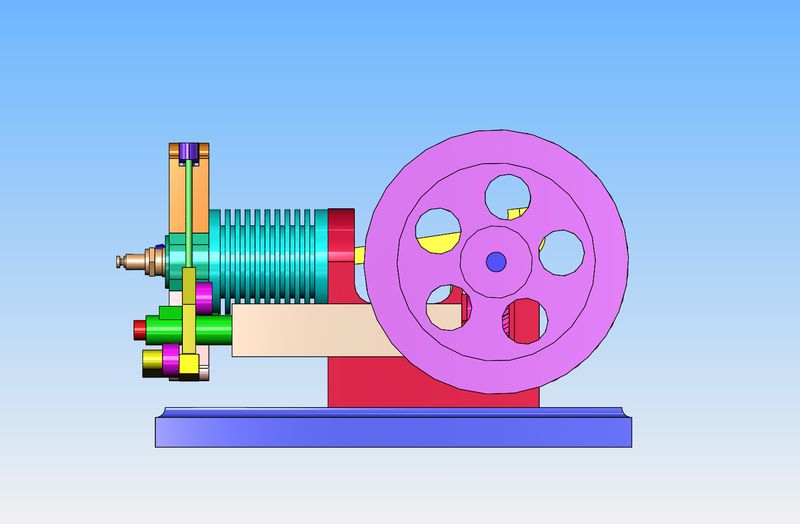

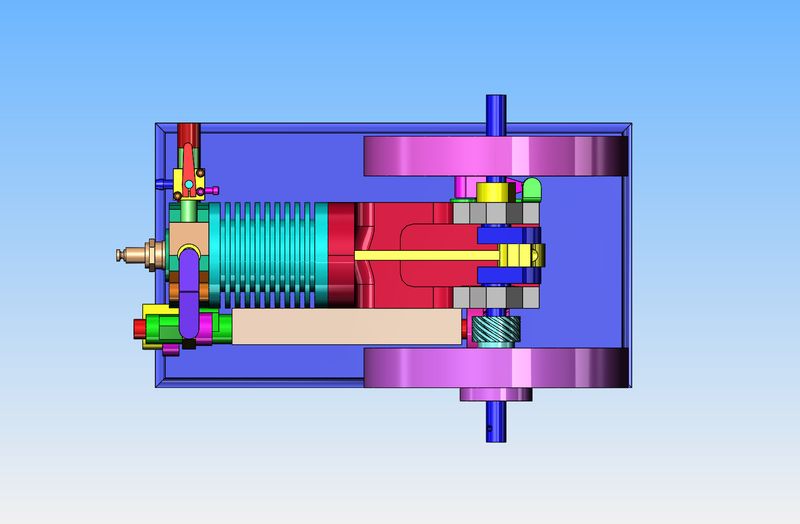

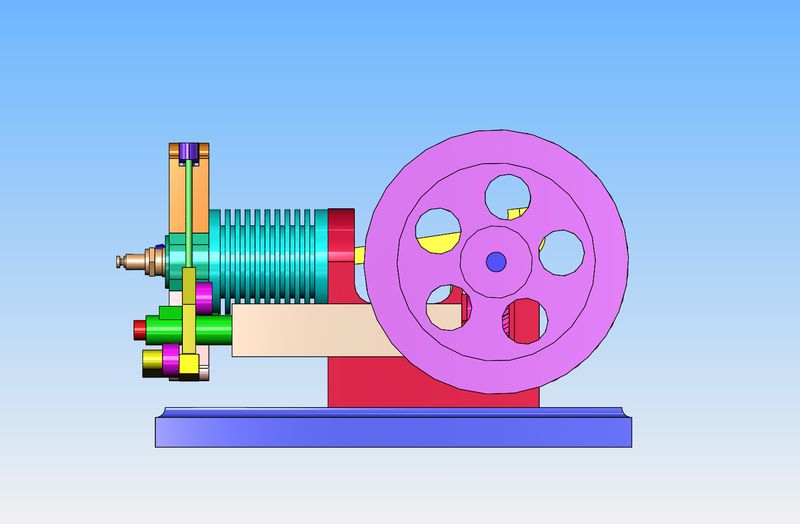

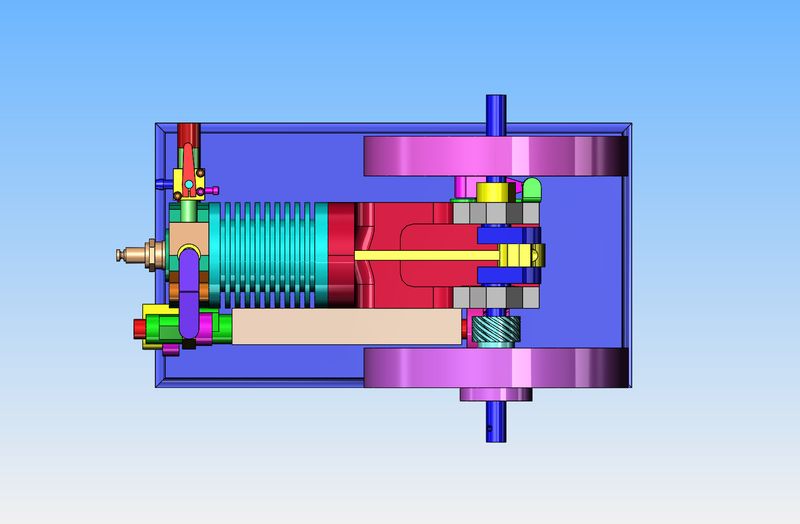

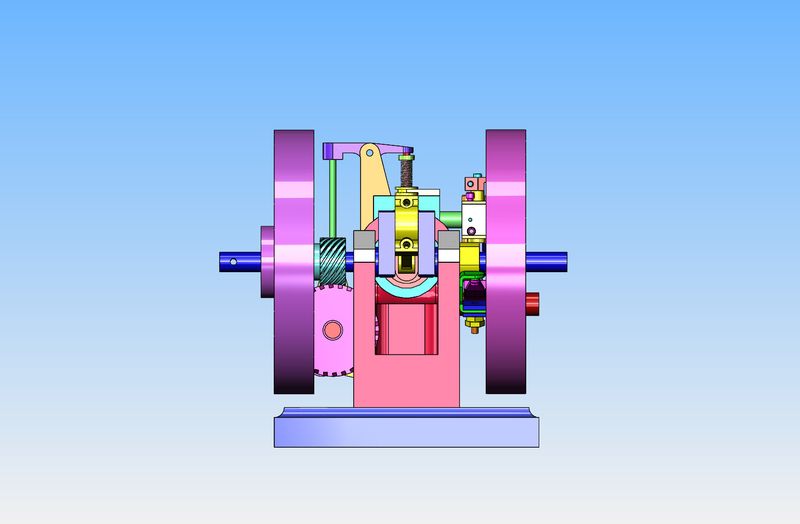

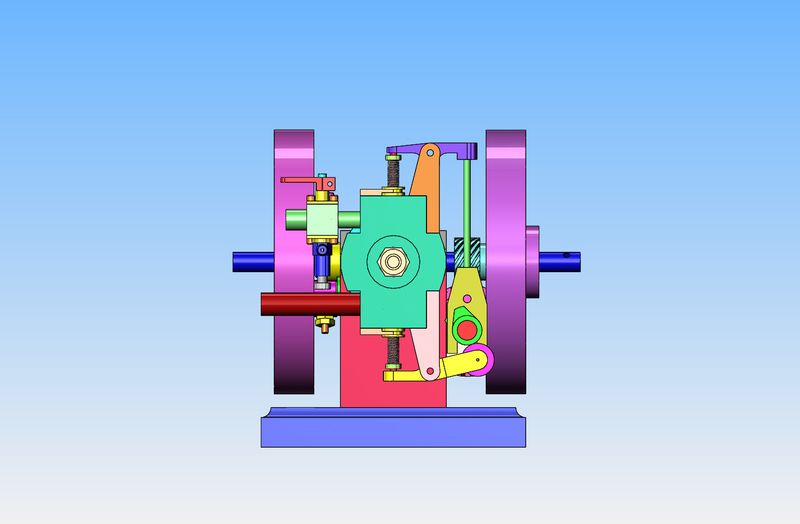

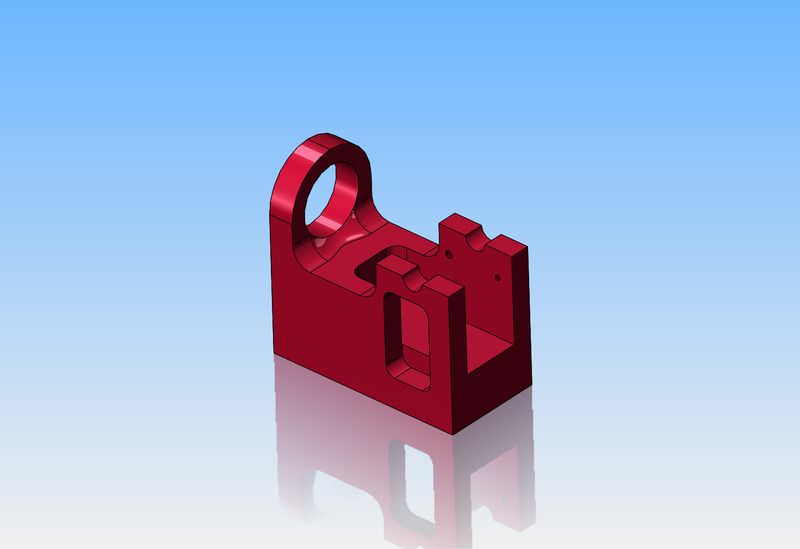

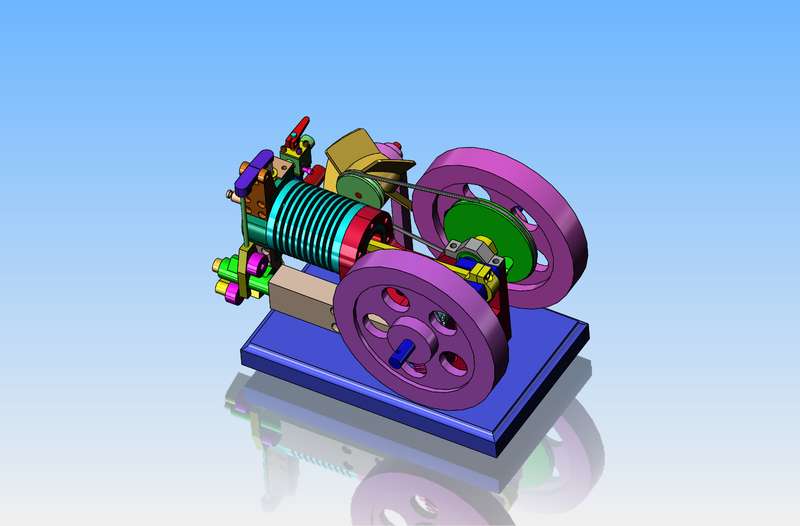

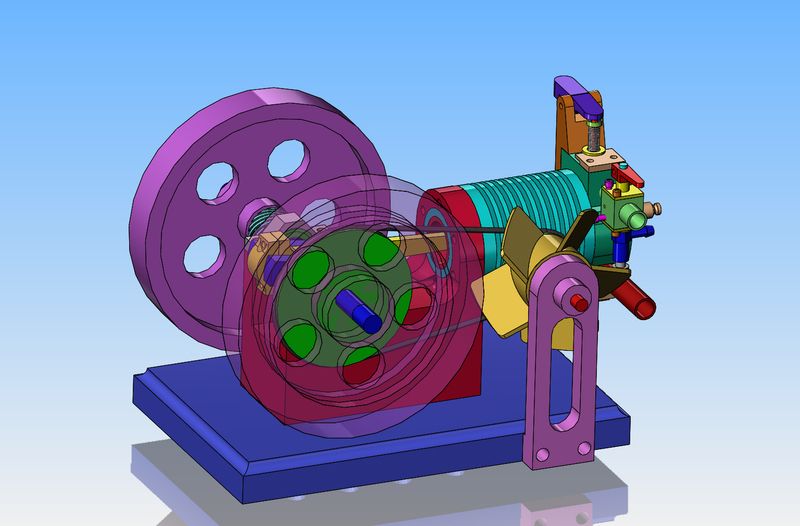

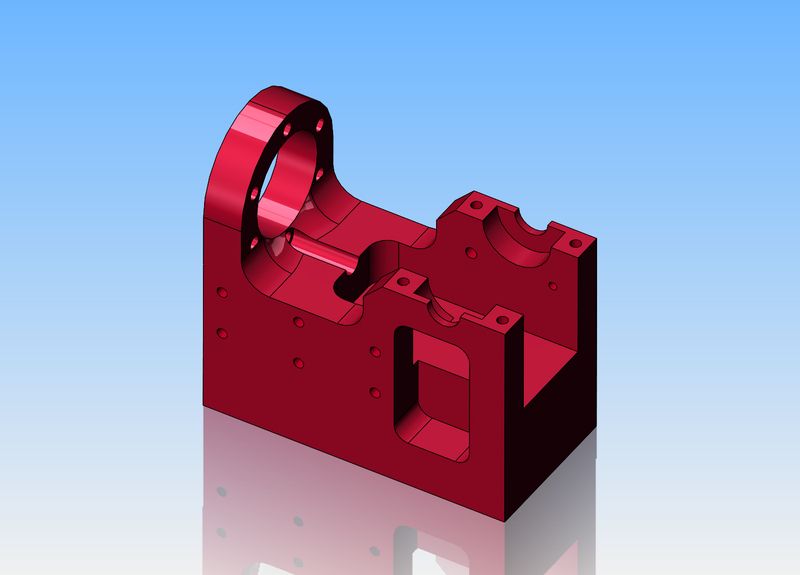

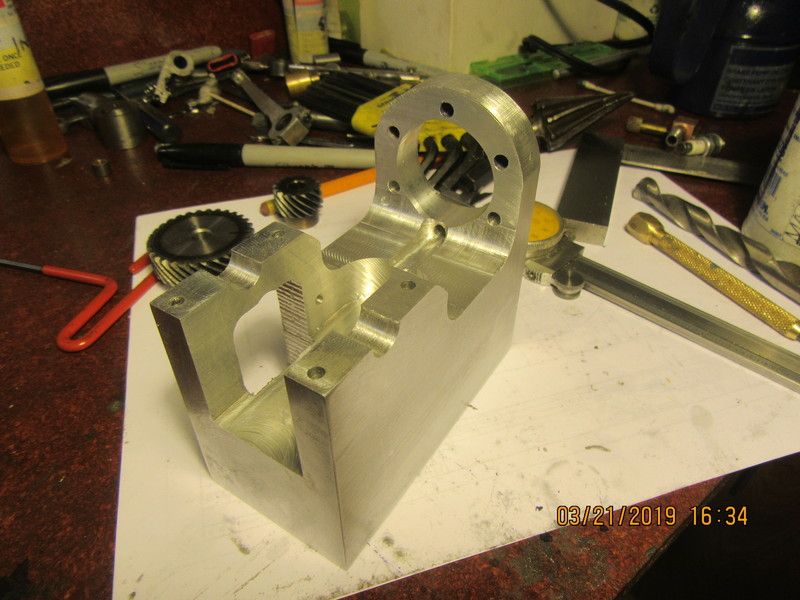

You fellows may remember---When I was chasing down helical gears for the sideshaft hit and miss engine I built, I bought a pair with 2:1 ratio off Ebay for $12.00 which is about $90 less than I paid for a set made in USA. I used the made in USA gears from Debolt to build my engine, but had the Ebay Chinese gears left over. I watched a YouTube video of an Edgar Westbury engine called the "Centaur" and was very impressed with the valve and sideshaft arrangement on it. Grandma was right--Idle hands truly are the devil's workshop. I was bored this week, so I've been messing around designing another sideshaft engine which uses the Chinese helical gears, and a valve arrangement similar to the Centaur engine. It's not a hit and miss engine--just a 4 cycle open crankshaft engine with a throttled carburetor. I might never build it, but it is interesting.