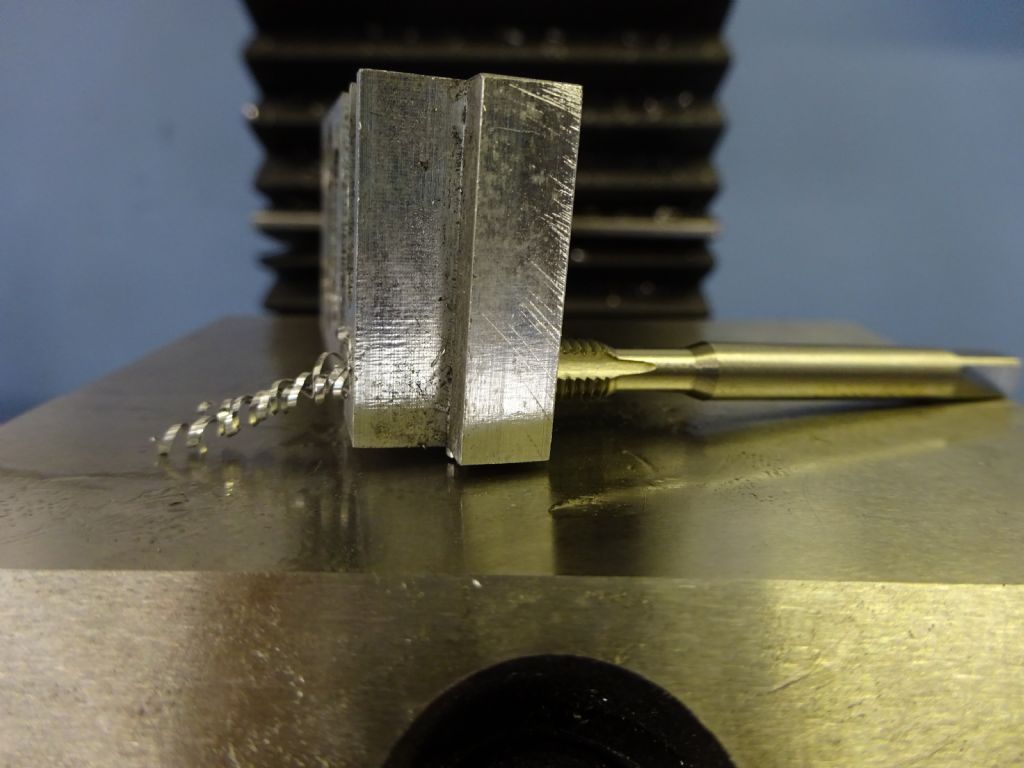

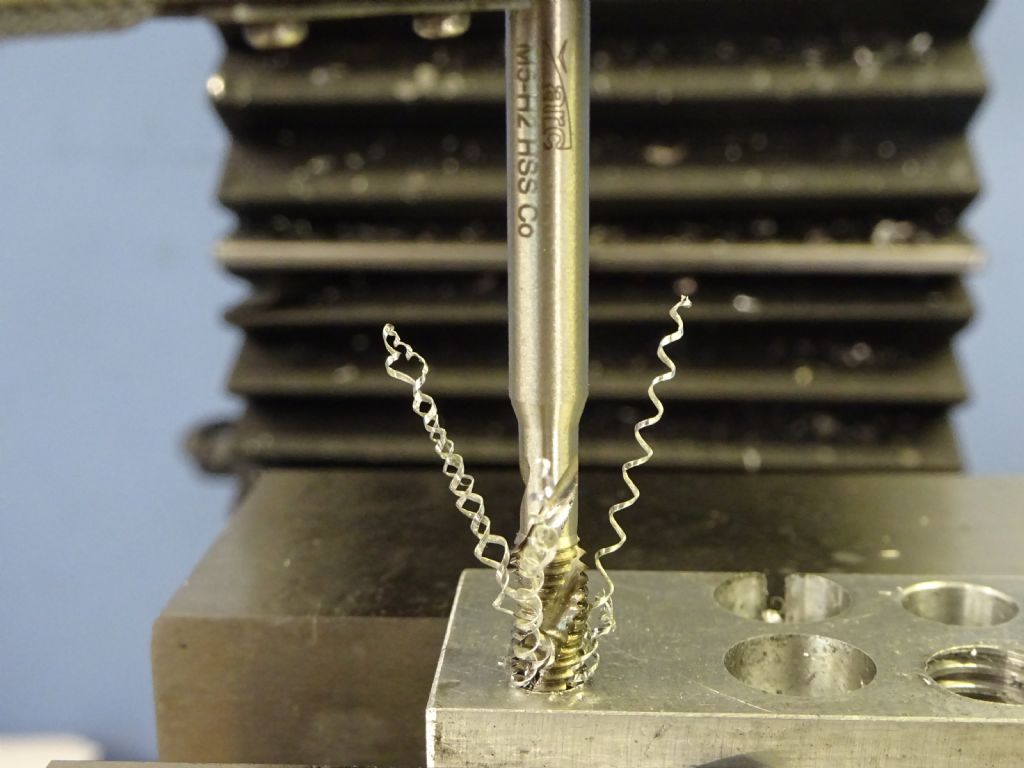

The smallest spiral flute or spiral tip that I have used is an M3, closely followed by a 6-32. I've not used the M3 as much, but never broken it, despite the fact that the spiral flute seems to leave very little metal in the tap. I have occasionally broken a 6-32 spiral tip tap. With the 1/4-20 or larger taps, you can be pretty aggressive with a spiral tip tap ... with 6-32, 8-32, and 10-24, you have to be more patient and sensitive. Oddly, the worst of these for me is the 10-24 - it seems big enough to be more aggressive, but the size of thread weakens it enough that it really won't stand too much. By contrast, I find 10-32 to be very forgiving.