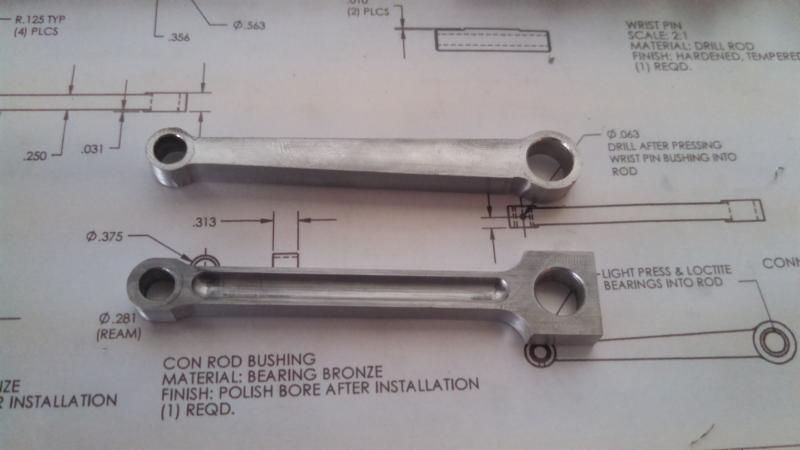

A little random knowledge about cam shapes and cam followers.--The Webster engine, in it's original form, did not have a roller on the rocker arm. This means that the cam should have had a radius on the cam flanks (instead of flat sides). With flat sides on the cam, every time it revolves the flat side of the cam will "slap" the rocker arm. If the cam had a radiused flank, it would raise the rocker arm in a more gradual motion and not "slap" it. Cams with flat sides do work well with a "roller follower" because the roller can more closely follow the contour of the cam without getting "slapped" each time the cam revolves.--So, your plan for a bearing as a cam follower is a good one.--However--This bit of arcane science doesn't seem to matter to much with the Webster, because it is a low powered, low revving engine, and seems to work just fine as designed. I am sure that on higher powered, faster revving engines this effect of flat flanked cams as opposed to radius flanked cams makes a large difference to engine performance. I don't think the Webster really cares too much, and will perform well either way.