cyclerider57

Member

- Joined

- Aug 7, 2011

- Messages

- 17

- Reaction score

- 11

I've been watching and reading for a little while on the site now and have finally started my first scale project. I'm an engine development engineer and race engine builder so I'm not new to machining but this will be my first micro build. I started yesterday by getting together some parts and laying them up in CATIA to 1/4 scale. I'll try to keep the build updated as it progresses because those are the threads that have inspired me to do a build (such as stevehuckss396 v8).

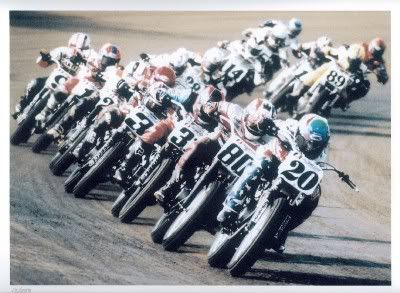

My build will be a 1/4 scale Harley-Davidson XR750 motorcycle engine. The XR750 is still the dominate engine in grand national dirt track racing and where my roots are so it was an obvious choice.

Regards.

-Jordan

My build will be a 1/4 scale Harley-Davidson XR750 motorcycle engine. The XR750 is still the dominate engine in grand national dirt track racing and where my roots are so it was an obvious choice.

Regards.

-Jordan