Looking good so far.

No blood spilt is always a plus

Robert

No blood spilt is always a plus

Robert

zeeprogrammer said:Niiiice looking flywheel Sam.

bearcar1 said:Square headed bolts and square nuts would be in order for fasteners. Square pegs doweling the pieces together wold also be of that time period. As for any 'weathering' or 'aging', have a look at Micro Mark, they carry a range of solutions widely used by model railroaders for achieving that look to their rolling stock. Parkerizing of the metal pieces would go a long way as well.

BC1

Jim

Philjoe5 said:Nicely done on the flywheel SAM. A neat method for building one up :bow:

Cheers,

Phil

Foozer said:Looking good so far.

No blood spilt is always a plus

Robert

sbwhart said:Great looking flywheel Sam this will be a very nice engine.

Sorry about your loss of blood hope its healing up well:- Table saws scare the c**p out of me.

Have fun

Stew

Bogstandard said:I just wish I had the knowledge and skills to make stuff like that, but it has always eluded me.

That is a very nice flywheel indeed, and I suppose when it is completely finished, it will look stunning. I can't wait to see what the rest will turn out like.

Bogs

kcmillin said:Ouch, a table saw. Jeeeeeez. your lucky you still have a finger. You do still have a finger, Right?

This looks like a neat engine, nice change from metal, eh.

Kel

PS. In your Avatar, Is that Doc Brown Showing Marty McFly how to work the flux capacitor. ;D :big: ;D :big:

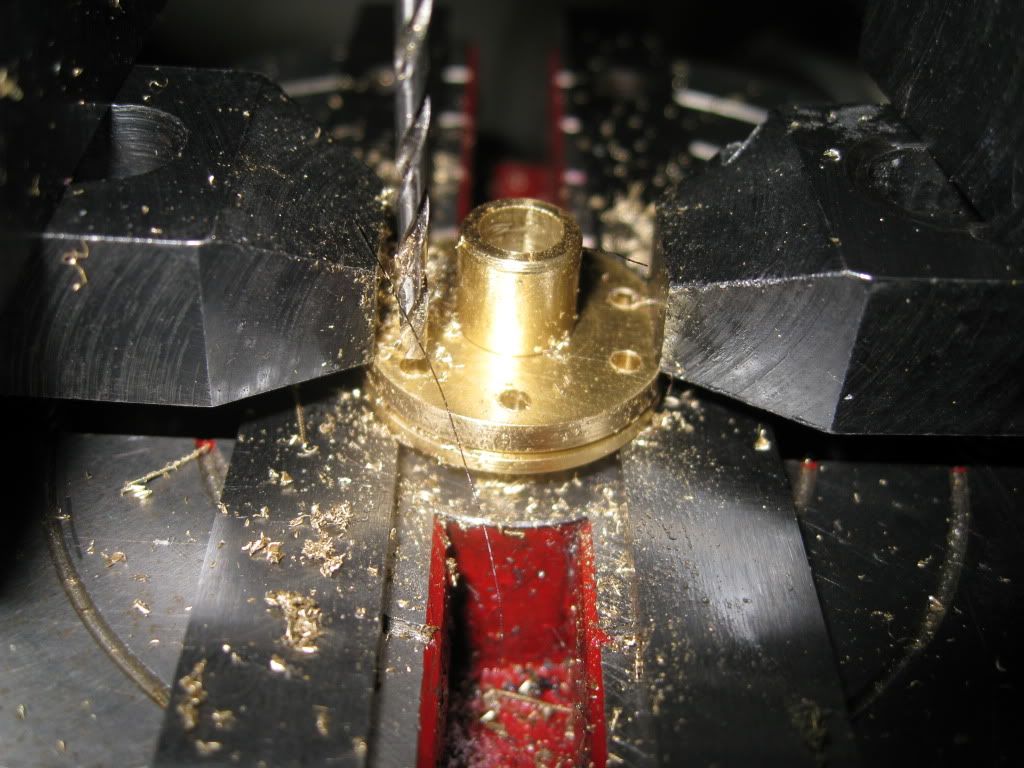

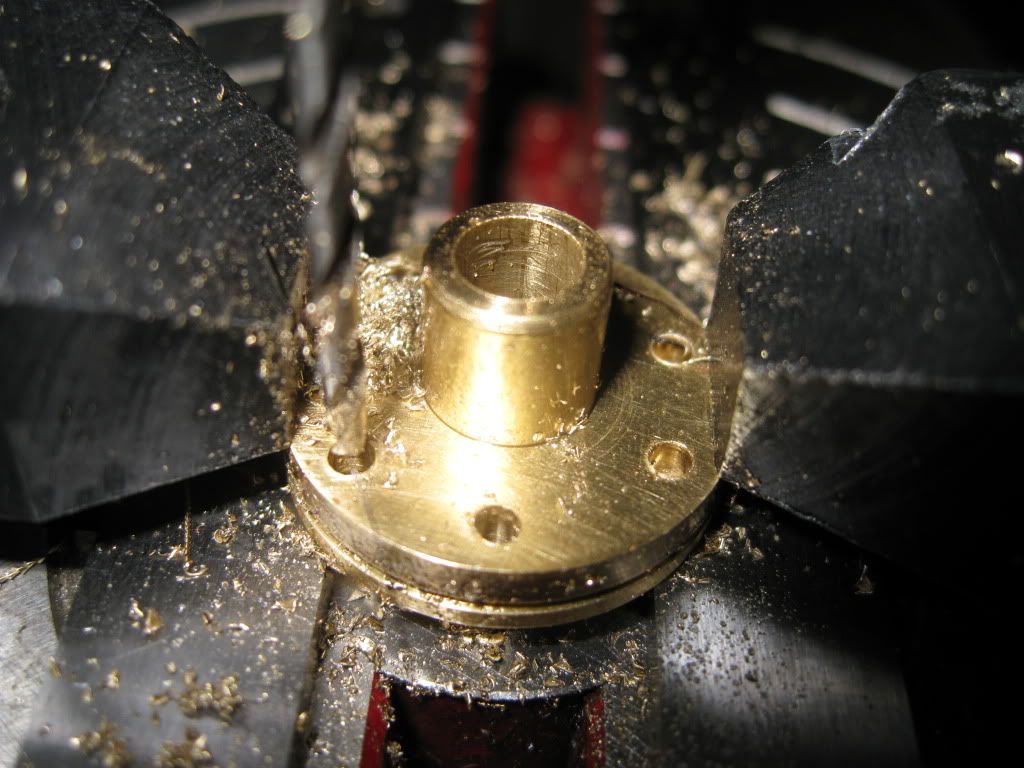

kcmillin said:Very Nice Sam. Congratulations on getting those pesky step clamps on such a small area.

What did you use to center the hub on the rotary table? With those step clamps it would seem a dial indicator would not work.

Kel

Enter your email address to join: