Thanks Zee for the confidence.

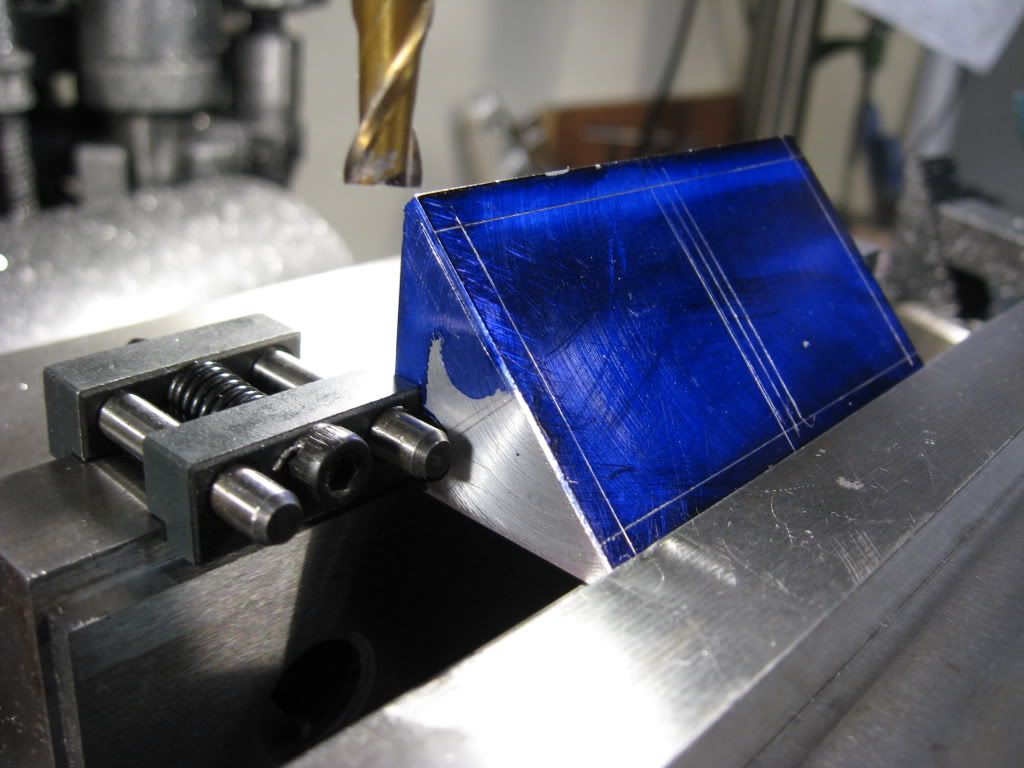

Well very little done tonight besides stare at the prints and scratch my head. I jumped onto the upper crankcase just for a change of pace. 3 lowers and I needed a break. I started the camshaft "hole"

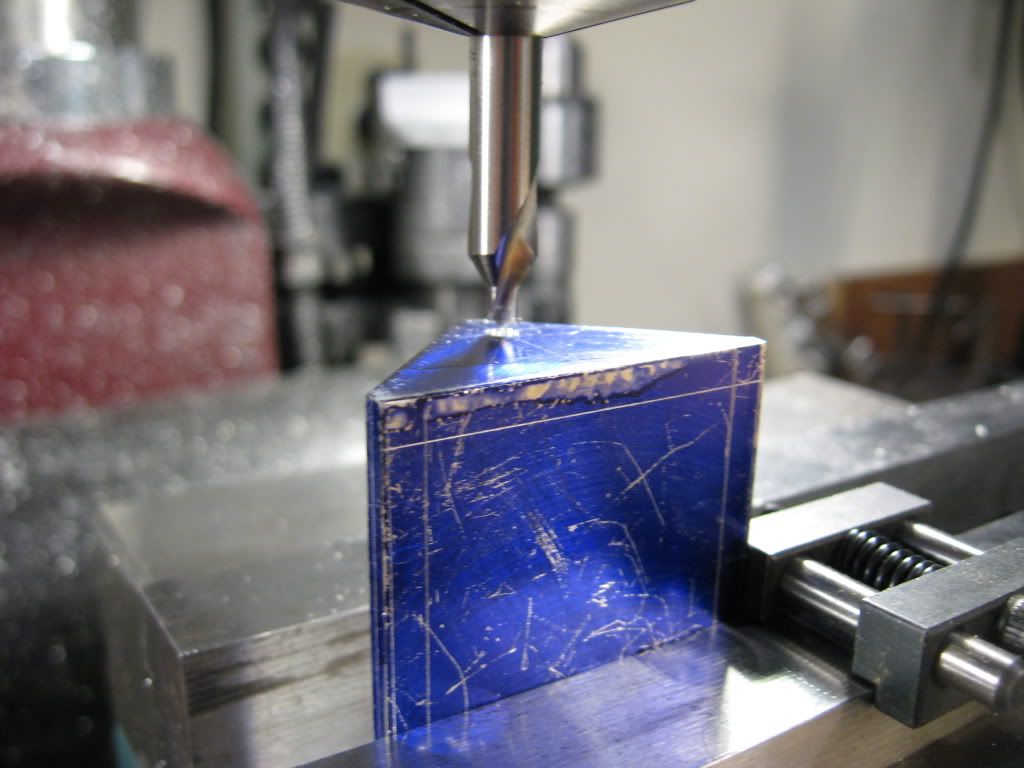

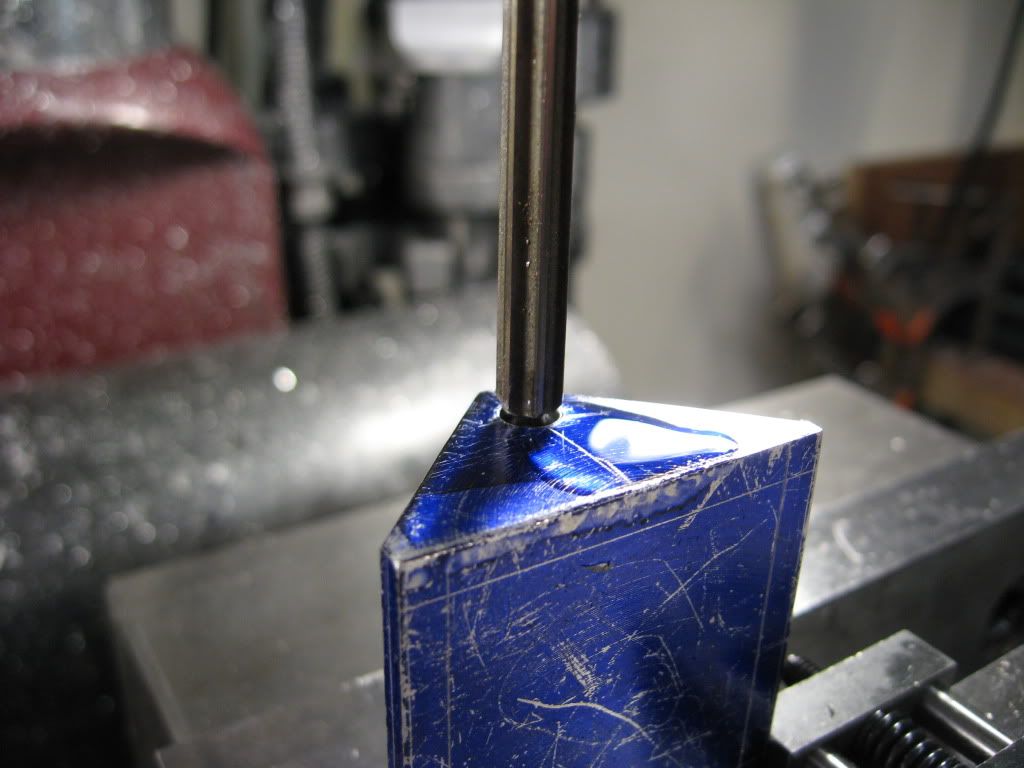

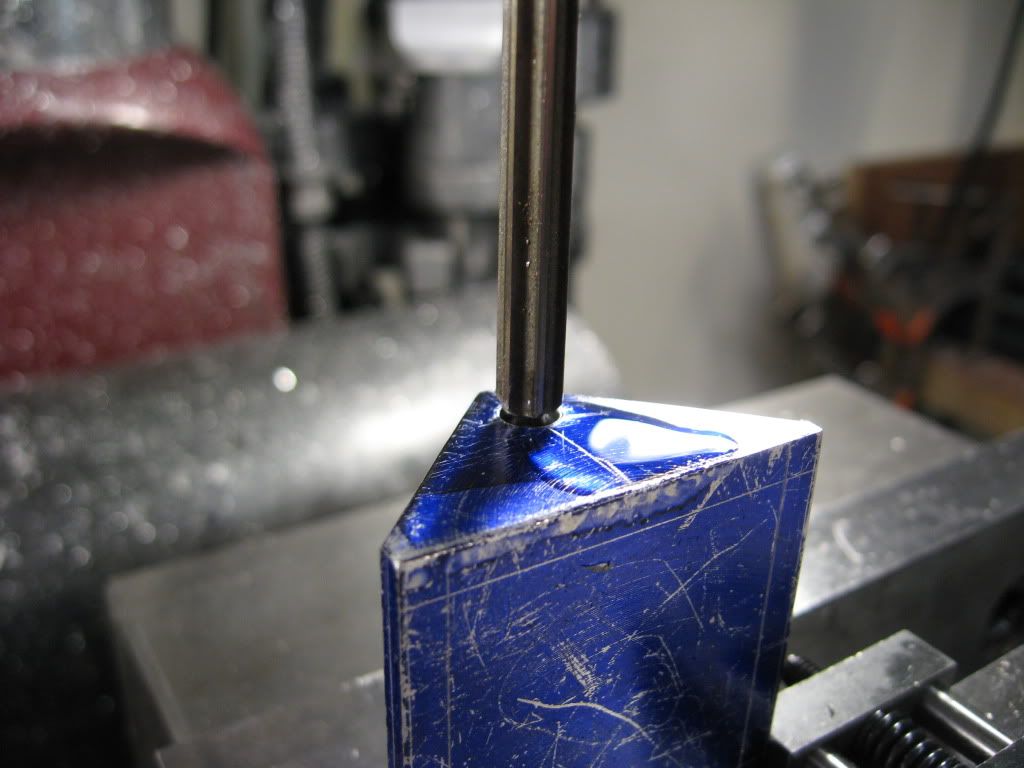

Center drilled the location

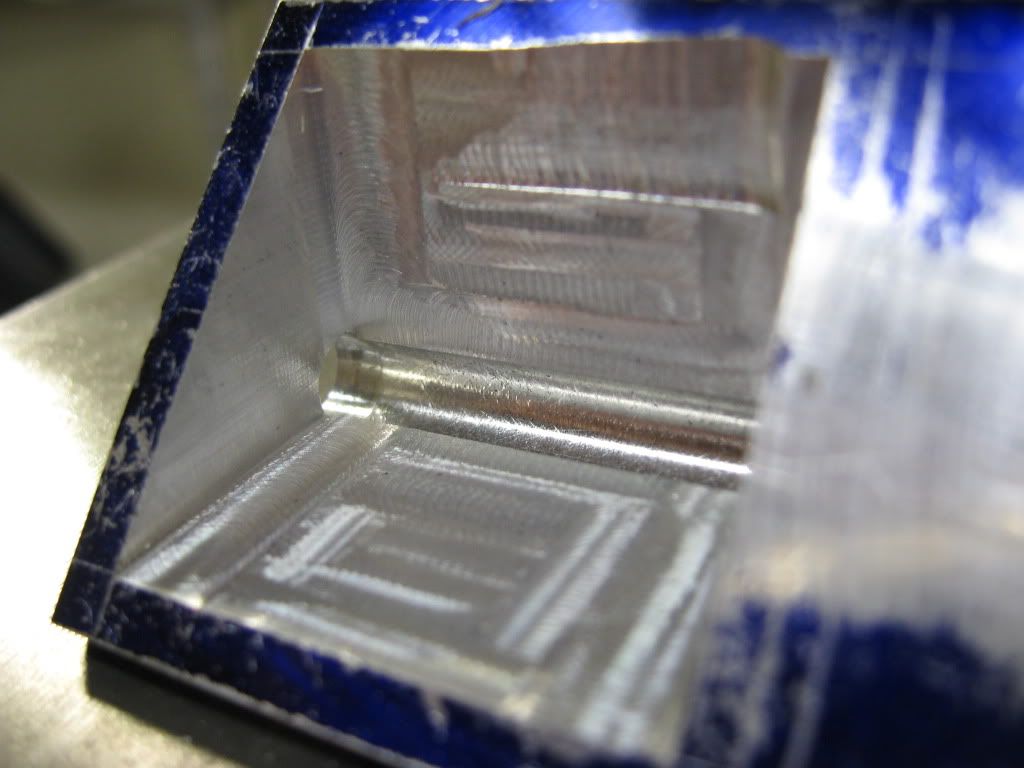

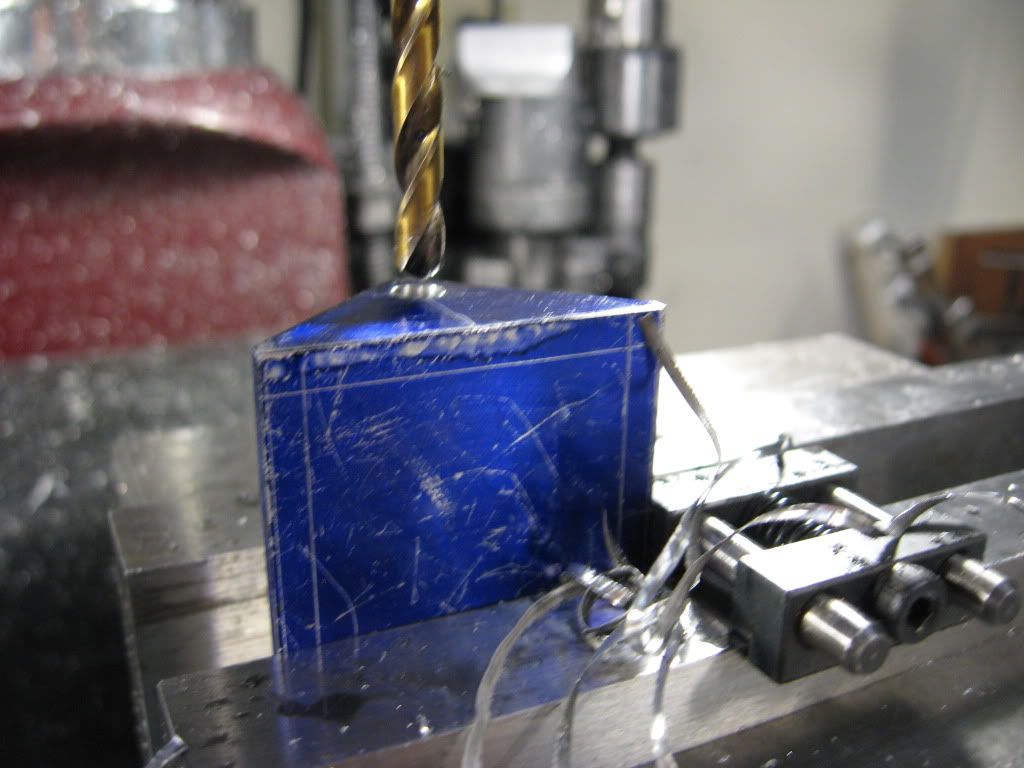

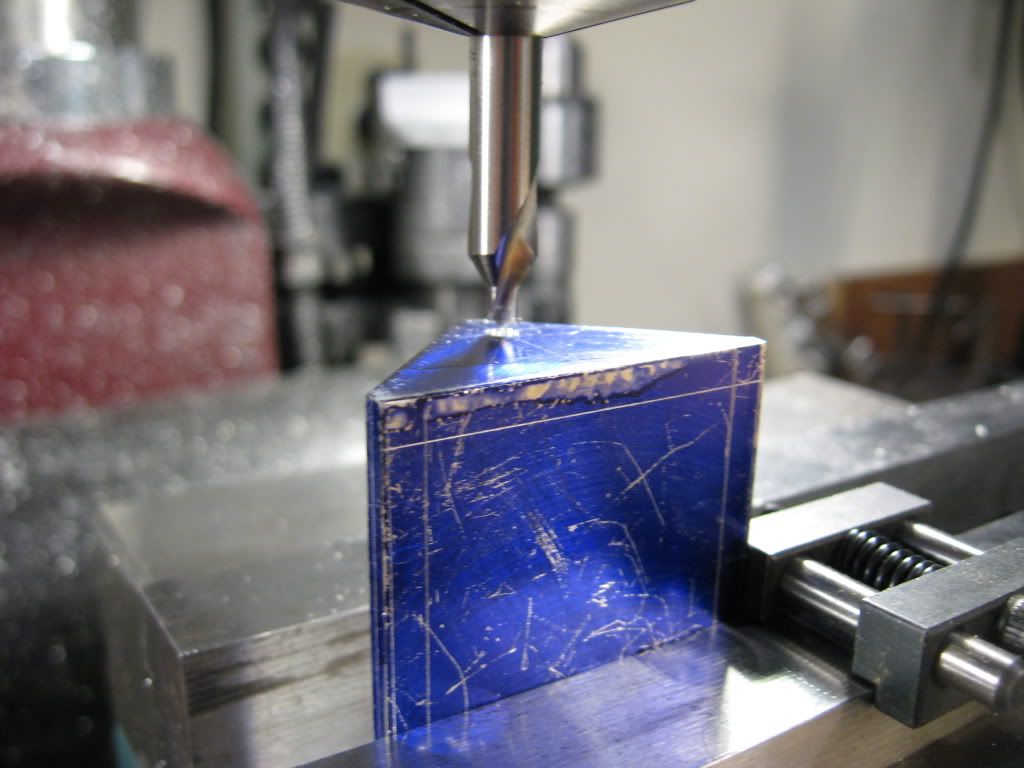

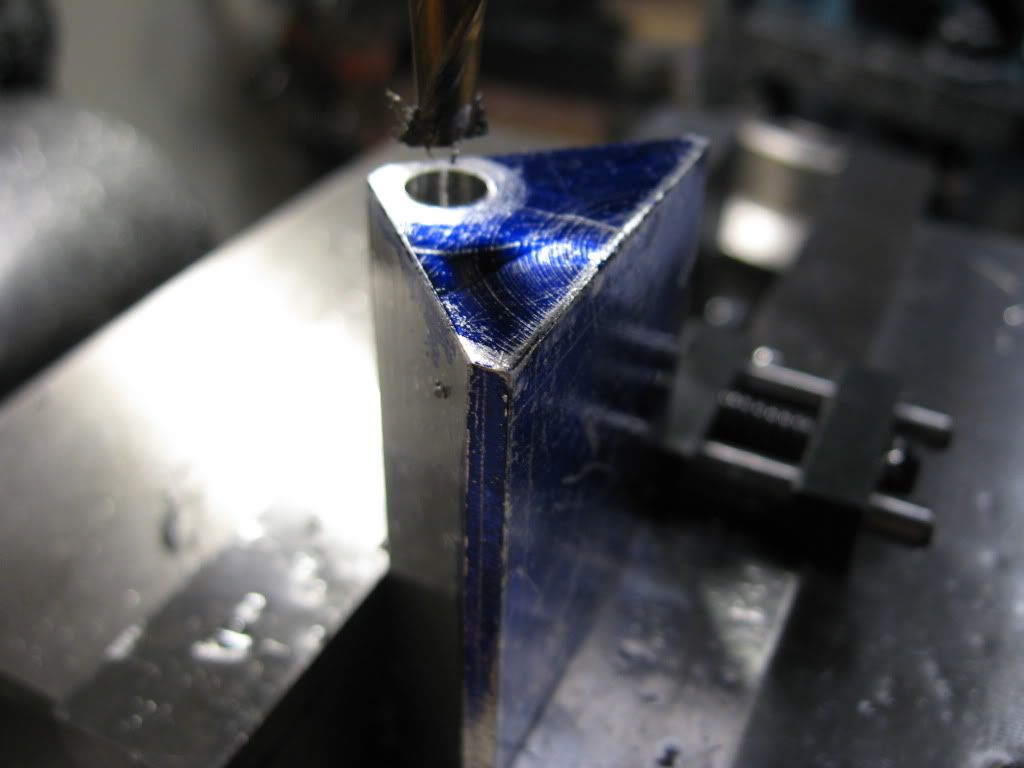

Drilled .201 hole about 5/8 of the way down. turned the block over and center drilled the other side and drilled again till the holes meet and a little further.

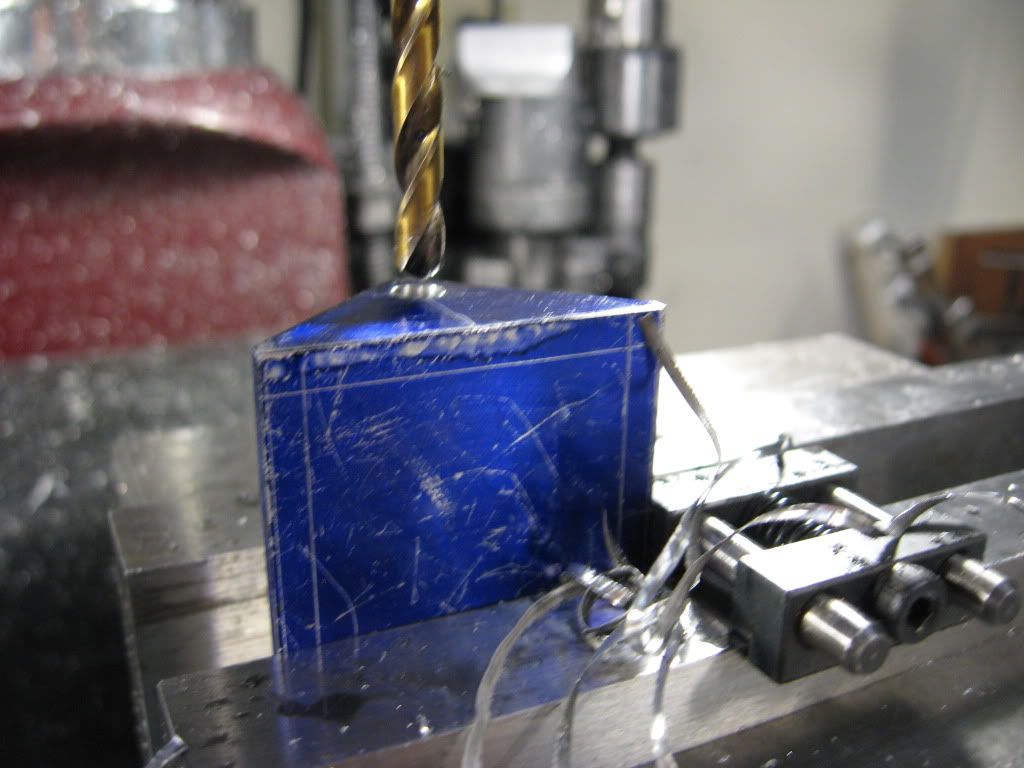

Then the 7/32 reamer came out. I went through the hole block one shot with the reamer

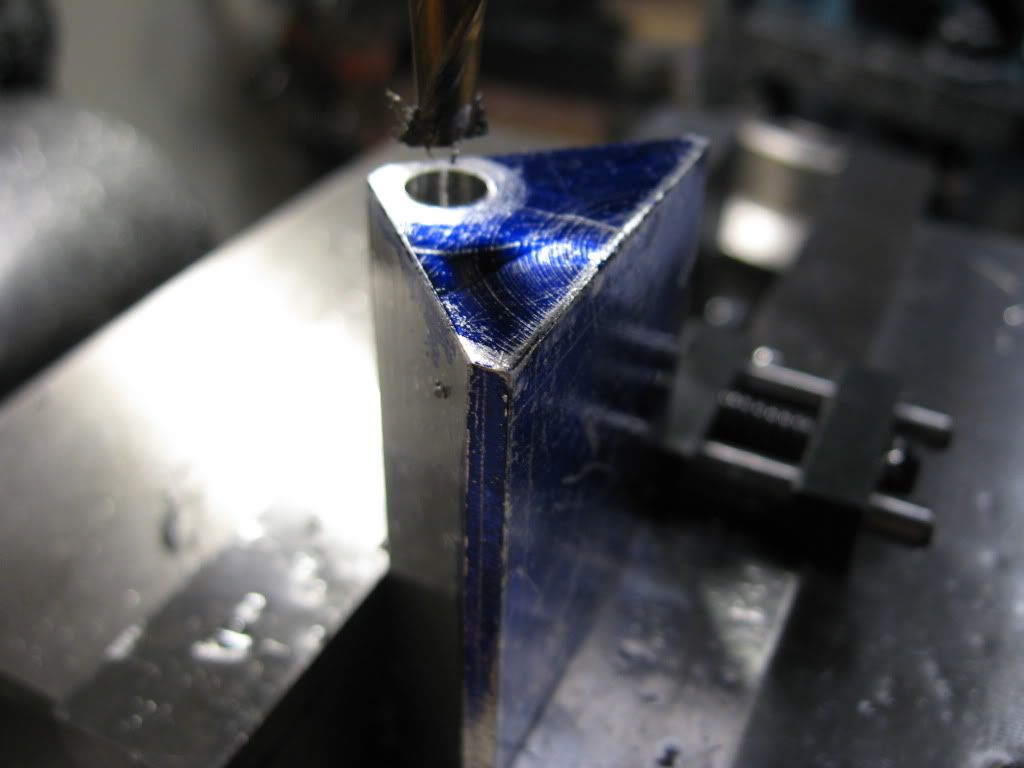

Then spot faced a 1/4" dia at rear of block for the larger bearing

Now this is where the head scratchin comes in.....no center support bearing??? The plans just show a front and rear bearing????

There has got to be a center support bearing.

Gail, am I missing something??

Before I break this set up down I need to figure something out. I wish EW did an assy drawing or a cross section through the vitals.

Thanks

Tony

Well very little done tonight besides stare at the prints and scratch my head. I jumped onto the upper crankcase just for a change of pace. 3 lowers and I needed a break. I started the camshaft "hole"

Center drilled the location

Drilled .201 hole about 5/8 of the way down. turned the block over and center drilled the other side and drilled again till the holes meet and a little further.

Then the 7/32 reamer came out. I went through the hole block one shot with the reamer

Then spot faced a 1/4" dia at rear of block for the larger bearing

Now this is where the head scratchin comes in.....no center support bearing??? The plans just show a front and rear bearing????

There has got to be a center support bearing.

Gail, am I missing something??

Before I break this set up down I need to figure something out. I wish EW did an assy drawing or a cross section through the vitals.

Thanks

Tony